Food Industry - Efficient Packaging and Preservation

In the food industry, heavy-duty rolls of aluminum foil are often used for large-scale food packaging, e.g. for industrial-grade food ingredients. Aluminum foils with a thickness of 0.05 - 0.2 mm are preferred, as this thickness ensures good barrier properties against moisture, oxidation and microbial contamination of the foodstuffs, as well as sufficient strength for large-scale packaging and transportation. For example, some large bakery enterprises purchase flour, sugar and other raw materials, the use of heavy-duty aluminum foil roll packaging, can effectively extend the shelf life, to protect the quality of food materials.

Pharmaceutical Packaging - Strict Quality Assurance

Pharmaceuticals have extremely strict requirements for packaging, and when heavy duty aluminum foil rolls are used for pharmaceutical packaging, products with a thickness of 0.03 - 0.1 mm are generally used. It can effectively block water, oxygen and light to ensure the stability and efficacy of the medicine. For some injectable drugs, blister packs made of heavy-duty aluminum foil rolls can provide reliable protection for the drugs and meet the strict requirements of Good Manufacturing Practice (GMP).

Building & Insulation - Increasing Energy Efficiency

In the building sector, heavy-duty aluminum foil rolls are commonly used for thermal and moisture insulation. Aluminum foil with a thickness of 0.1 - 0.5 mm is used for roof and wall insulation in buildings. It reflects heat and reduces a building's dependence on cooling equipment such as air conditioning, resulting in energy savings. For example, in the external wall insulation systems of some large commercial buildings, aluminum foil is used in combination with insulation materials to significantly improve the building's thermal insulation performance and reduce energy consumption.

Electronic Equipment - Heat Dissipation and Shielding

Heavy-duty rolls of aluminum foil play an important role in the production of electronic equipment. Aluminum foils with a thickness of 0.02 - 0.1 mm are used for heat sinks and electromagnetic shielding of electronic components. In the thermal modules of computer CPUs, aluminum foil heat sinks quickly transfer heat away from the device and prevent it from overheating. At the same time, in electronic equipment that is sensitive to electromagnetic interference, such as medical electronics, aluminum foil is used for electromagnetic shielding to ensure stable operation of the equipment from external electromagnetic interference.

Automotive Manufacturing - Multiple Application Scenarios

The automotive manufacturing industry is also inseparable from heavy-duty aluminum foil rolls. In automotive thermal and acoustic insulation systems, aluminum foil with a thickness of 0.05 - 0.3 mm is laminated with other materials and used in engine compartments, doors, etc. to provide both thermal and acoustic insulation. In addition, aluminum foil is used in the manufacture of automotive batteries as a material for the battery's fluid collector, which enhances the battery's performance and safety.

Aerospace - high standard applications

The aerospace industry has very high material requirements and heavy duty aluminum foil coils have their place. High-strength aluminum foils with a thickness of 0.03 - 0.2 mm are used for thermal insulation in aerospace equipment, as well as shielding materials for electronic devices. Thanks to its light weight, high strength and corrosion resistance, aluminum foil meets the stringent requirements of aerospace equipment for lightweight and high-performance materials.

Chemical Industry - Corrosion Resistant Packaging

Chemical products are often corrosive, and heavy-duty rolls of aluminum foil are typically used in thicknesses of 0.08 - 0.3 mm for chemical packaging. The oxidized layer on the surface of aluminum foil provides reliable packaging protection against most chemicals. For example, some highly corrosive chemical reagents can be packaged in aluminum foil to ensure safety during transportation and storage.

Freezing & Refrigeration - Low Temperature Protection

In the freezing and refrigeration industry, heavy-duty catering foill rolls are used to package frozen food, refrigerated pharmaceuticals, etc. Catering foil with a thickness of 0.04 - 0.2 mm maintains its flexibility and barrier properties at low temperatures, preventing moisture penetration and avoiding freezing or deterioration of the product. Frozen foods such as meat and seafood stored in large-scale cold storage facilities can be better preserved in terms of freshness and quality by using aluminum foil packaging.

Solar Industry - Ancillary Material Applications

Heavy duty rolls of aluminum foil are used as an ancillary material for solar panels in the solar industry. Aluminum foils with a thickness of 0.02 - 0.1 mm are used for the manufacture of frames, backsheets and other components of the panels to protect the cells, enhance the structural strength of the panels and reflect light to increase the efficiency of photovoltaic conversion.

Packaging and Printing - A Fine Look

In the packaging and printing industry, heavy-duty rolls of aluminum foil are used to produce high-grade packaging materials. Aluminum foils with a thickness of 0.01 - 0.08 mm are printed and laminated for use in gift boxes, premium tobacco and wine packaging. The metallic luster of aluminum foil enhances the aesthetics and texture of the packaging and attracts consumers' attention.

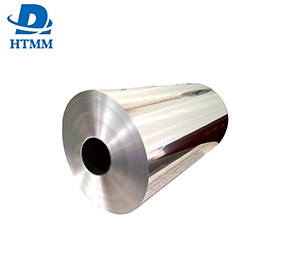

How to select high quality heavy duty aluminum foil rolls

Check the product specifications and parameters: carefully check whether the specifications of the aluminum foil rolls, such as thickness, width, length, etc., are in line with your needs, and pay attention to the material composition of the product to ensure that it meets the relevant industry standards.

Check the appearance quality: the surface of best aluminum foil rolls should be smooth and flat, without obvious scratches, holes, folds and other defects. The color of the aluminum foil should be uniform and consistent, without oxidation discoloration.

Understand the production process: advanced production process can ensure the stable quality of aluminum foil. For example, the use of high-precision rolling equipment and strict quality control system produces aluminum foil with small thickness tolerance and more reliable performance.

Refer to the brand and reputation: Choose the brand with good reputation and credibility, such as the products of HTMM Aluminum Foil Factory. Brands that have been tested in the market for a long time are more guaranteed in terms of product quality and after-sales service.

HTMM Aluminum Foil Factory has been investing in R&D and optimizing the production process for more than 10 years, with strict quality control at every stage, from raw material purchasing to finished products leaving the factory. With advanced production equipment and a professional technical team, we are able to customize heavy duty aluminum foil rolls of various specifications according to the different needs of our customers. Whether it's for food, pharmaceuticals, or electronics or construction, HTMM Aluminum Foil Factory provides best aluminum foil to protect our customers' production and applications. When you choose heavy-duty aluminum foil rolls from HTMM Foil Works, you choose quality, reliability and professionalism.