Applicable Packaging Form Types for 7 Micron 8079 Aluminum Foil

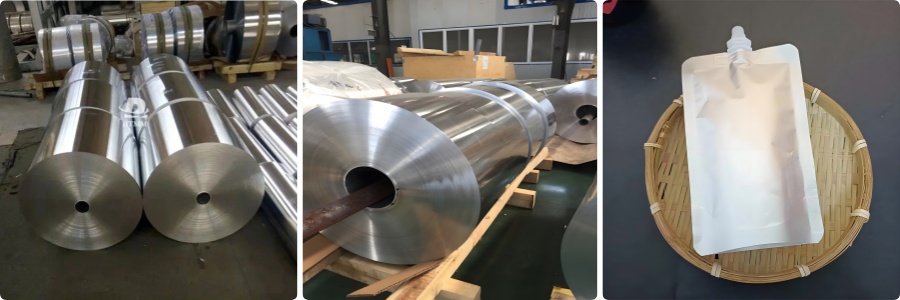

There are many foil attributes and properties that make the 7 Micron Aluminum Foil 8079 Jumbo Roll multi-functional for packaging applications in various foil types. In the food industry, it is most often laminated with paper or plastic film to form pouches or wrappers for packaging snacks, chocolate, and other dairy food items that might be susceptible to moisture, light and oxygen permeation. It is also offers high flexibility and permits free-form folding and tight wrapping without cracking making it very applicable to confectionary and baked goods packaging.

In the pharmaceutical industry, 8079 foil at 7 microns is used as blister packs, sachets, and strip packs. This foil is thin and strong enough to keep medicines safe from outside contamination but still easily opened by the consumer. For tobacco products, the foil is laminated to paper to create inner liners that preserve the aromas and quality of the tobacco. With that said, the 8079 aluminum foil is one of the most trusted and reliable packaging materials used for sensitive packaging applications.

Why Laminated Aluminum Foil Packaging is Becoming Increasingly Popular

The shift toward laminated packaging materials shows the importance of 8079 aluminum foil. When it is used as the best laminating foil, it is laminated to paper, polyethylene, or polyester films and make a multi-layer structure that is stronger and performs better. The laminated foils allow for good seals for airtight packages, the ability to be printed on for branding purposes, and a metallic appearance that improves the aesthetics of packaged items.

Laminated foil packaging has gained traction primarily due to the benefits to sustainability laminated foils provide. Thinner foils, like 7-microns, use less raw material, thus decreasing the overall weight of the package which lowers the shipping costs. At the same time, laminated foils develop barrier properties that will give product a longer shelf life, which will help reduce food waste. The associated environmental and cost savings has contributed to the popularity of laminated foils with many producers.

Benefits of 8079 Alloy for Laminated Foil Applications

The 8079 aluminum contains considerably more iron and silicon than typical aluminum alloys which greatly enhances elongation, tensile strength, and tear properties. Elevated elongation and tensile strength and tear properties provide added value to ultra-thin laminated foils like the 7-Micron Aluminum Foil 8079 Jumbo Roll because laminated foils can now be laminated printed, cut and packaged at a higher rate without no risk of tearing. In addition, the surface finish left on the foil provides smooth lamination edges when laminated with adhesive coatings that improves the properties of the adhesive.

The 8079 jumbo roll of 7 micron aluminum foil has positioned itself as one of the foremost solutions for modern foil for packaging applications. Used in food, pharma, or tobacco packaging, it provides substantial barrier properties, flexibility, and durability, but it is also the best laminating foil for packaging that supports product safety and attractive branding while providing lightweight, sustainable packaging. It is apparent that the unique advantages presented by 8079 aluminum foil will continue to lead innovation and reliability in packaging at an international level.