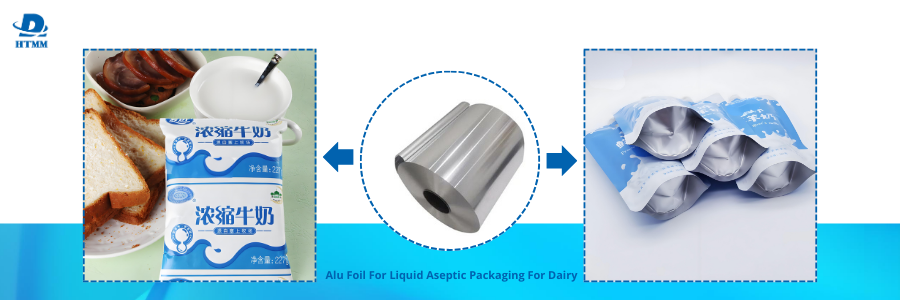

The Structure of Flexible Packaging by Food Flexible packaging typically has many layers, with each layer being specialized for a certain goal. The layers consist of plastic films (PET or PE), adhesive layer and aluminum foil layer. The flexible packaging aluminum foil layer is the core barrier layer in the flexible packaging structure. Its main responsibility is to block light, oxygen and moisture from entering the bag, which spoils the contents through biological contamination by bacteria.

In this multilayer structure, the aluminum foil helps provide mechanical strength and thermal resistance to the package, which is desirable in a package subjected to processes such as pasteurization, sterilization, or freezing. The 7 micron aluminum foil jumbo roll will be even more suitable here, where a balance of flexibility and performance properties are needed, along with the lowest amount of material weight and cost.

Why 7 Micron Aluminum Foil Jumbo Roll?

The 7 micron aluminum foil jumbo roll is widely used in laminates for food-grade pouches, lids, and wraps, providing a thin aluminum foil option that represents durability. The 7 micron aluminum foil is the preferred choice for high-speed automatic packaging lines because of its excellent machinability, and it does not need tearing, which allows it to maintain its formed shape. Furthermore, despite the low gauge thickness of 7 microns, it maintains significant attributes required in flexible packaging aluminum foil, including:

Excellent gas and moisture barrier properties

Good thermal conductivity which will allow for heat sealing

Lightweight with good structure, which provides integrity

Compatible with printing and lamination processes

These properties all make it ideal for snack packaging, dairy product lids, coffee pouches, and pharmaceutical blister packs.

Alloy Types: 1235 vs. 8079 Aluminum Foil Rolls

Using the proper alloy to manufacture aluminum foil has an effect on how well it performs. Two alloys that are commonly used in flexible packaging are the 1235 aluminum foil roll and the 8079 aluminum foil roll. Both grades are commonly accepted in the packaging industry, but each has different properties.

.png)

1235 Aluminum Foil Roll

Composition: Pure aluminum (99.35% minimum)

Strengths: Great ductility and corrosion resistance.

Applications: Used widely in food and beverage packaging, cigarette foil, and household foil.

Usefulness for Flexible Packaging: The 1235 aluminum foil roll offers suitable packaging options for light weight products while considering moisture and air resistance with good flexibility.

8079 Aluminum Foil Roll

Composition: Contains more iron and silicon than the 1235 aluminum foil, and increased strength.

Strengths: Better tensile strength, better resistance to puncturing, and better elongation.

Applications: Good options for pharmaceutical packaging, cosmetic seals, or other high barrier packs.

Usefulness for Flexible Packaging: The 8079 aluminum foil roll offers better performance for more demanding applications in situations where higher durability and barrier protection is required such as in medical or high fat content food products.

Choosing the Right Aluminium Foil for your Application

Whether you use 1235 or 8079 for your aluminium foil flexible packaging, you will want to observe the specific use of the material being packaged. Lighter weight products, such as snack food or dry goods, will probably work just fine with a 1235 aluminium foil roll. However, if the product has aggressive content, such as oily food or medicines, the 8079 aluminium foil roll offers a higher level of mechanical properties that provide more protection.

In either case, a 7 micron aluminium foil jumbo roll will provide converters and manufacturers the ability to be very efficient producing large quantities with predictable quality and performance.

Due to the competitive space of food and pharmaceuticals, material choice is almost always critical. Flexible packaging aluminium foil is well known to be an industry standard material because of its dazzling barrier properties and lightweight flexible nature. The 7 micron aluminium foil jumbo roll has gained popularity with manufacturers looking for quality and efficiency. wheter you choose a 1235 aluminium foil roll for standard applications or with a heavier gauge 8079 aluminium foil roll for high performance applications, the right tooling choice will ensure packaged products have a longer shelf life, and are packaged to the liking of the consumer.

By being aware of the nature of flexible packaging and the various benefits of each alloy of aluminum, companies are able to make educated decisions, which will benefit their packaging operations for cost, performance, and sustainability.