1235 O aluminum foil is part of the 1××× series of pure aluminum foil, or foil that has aluminum as the main chemical component, having over 99.35% aluminum with further ticks of just iron and silicon. This major purity gives the 1235 aluminum foil fantastic basic properties, with the "O" representing its annealed state. Having undergone full annealing treatment; the internal microstructure of the aluminum foil becomes more uniform and stable, relieving internal stresses induced during the processing, leading to the best plasticity and flexibility in aluminum foil.

.jpg)

The thickness of this aluminum foil is precisely defined as 6 microns. What does 6 microns mean? It is about one-tenth the thickness of a human hair. This ultra-thin characteristic of the 1235 O 6-micron aluminum foil offers many benefits in terms of packaging functionality. First, its very light weight greatly reduces packaging material weight. This means less energy consumption during transport and ultimately supports current green and environmentally friendly development concepts. Second, its lightweight and thin characteristics improve the foil's flexibility, allowing it to be easily bent, folded, and wrapped to accommodate a variety of complex packaging shape needs.

The 1235 O 6-micron aluminum foil also possesses excellent ductility. During processing, it can experience significant stretching without breaking as part of subsequent composite and printing processes. It also features a smooth and clean surface free of burrs to ensure the visual aspects of the packaging and, at the same time, the bond when combining with other materials are satisfactory.

Additionally, 1235 O 6 micron aluminum foil also has good electrical and thermal conductivity. While these properties are not a primary consideration in the likely uses in the packaging space, they might apply in some cases in special or unique packaging. Most importantly, it is non-toxic, odorless, and meets the hygiene specifications required for packaging materials in food and pharmaceutical packaging, while not contaminating the contents in the package.

1235 O 6 Micron Aluminum Foil: An Invaluable Product

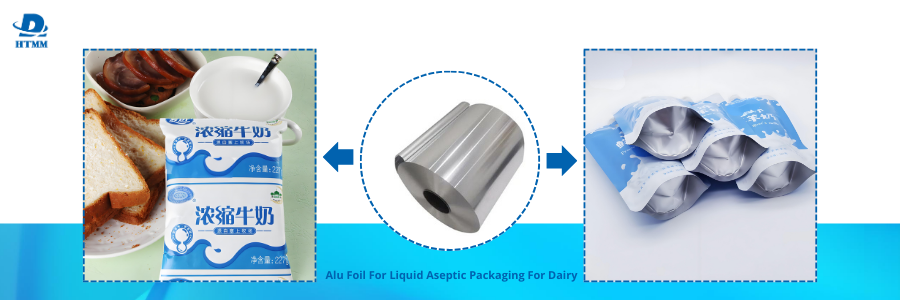

(1) Food Soft Packaging Industry

In the food "soft packaging" industry, 1235 O 6 micron aluminum foil has an irreplaceable status in the industry. It is often used to manufacture many types of composite packaging bags for food products, for example, snack foods bags, ready-to-eat food bags, and baked goods packaging bags.

Snack foods have high standards for packaging heat sealing and freshness. The 1235 O 6 micron aluminum foil when combined with plastic film or other materials are formed into a very tight barrier that can block out oxygen, moisture, and light so the snacks don’t get exposed to humidity, oxidation or staleness. While keeping the snacks crispy with their original taste in these composite packages, the packaging for what snacks are highly strict.

For ready-to-eat foods and baked goods, even with a composite package bag, for example a ready-to-eat meals and with cooked items, this composite package, not only provides shelf life protections for food storage, it creates preserved flavor neighborhood without cross-contaminating the flavor.

In addition, the 6-micron ultra-thin thickness of the food packaging bag, or as the consumer feels lightweight to carry consumption use. In addition, when printing the 1235 O 6 micron aluminum foil surface smooth to impact the product and printed take operation, because it suggests that you will be able to print fine patterns and excellent food information display on your packaging bags, improving your product's market competitiveness even more.

(2) Pharmaceutical Packaging Segment

The pharmaceutical packaging segment has also included 1235 O 6-micron aluminum foil for aluminum-plastic blister packaging of pharmaceuticals and for some types of pharmaceutical packaging bags.

Aluminum foil for pharmaceuticals in blister packaging must have a high level of flexibility and formability and the 1235 O 6-micron aluminum foil meets those specifications perfectly. During the forming operation, it can mold precisely and accurately to the shape of the die, producing neatly formed and standardized blisters, giving pharmaceuticals independent sealed compartments. It also has excellent barrier properties that totally exclude the effects of moisture, oxygen, and light on the pharmaceuticals, keeping these in a stable and efficacious state throughout their shelf life. Furthermore, this aluminum foil is easy to puncture to allow patients to access the pharmaceuticals but maintain the integrity of the blister packaging, protecting against contamination during storage and transit.

(3) Personal Care Product Packaging Market

The packaging of personal care products has specific expectations regarding how the material looks, barrier performance and how easily it is processed. In this sector, both 1235 O 6-micron aluminum foil and 1235 O 9-micron aluminum foil are used extensively. The packaging of cosmetics, detergents, skin care products and other products, uses these two products.

For cosmetics, often the products contain active ingredients that are susceptible to oxidation, hence they need to be protected from air (oxygen) and light. Packaging containers or bags that are produced by laminating 1235 O 6-micron aluminum foil to another substrate are very capable at blocking oxygen and light, specifically protecting the active ingredients in the cosmetics from degrading and giving marketers valuable shelf life. In detergent and skin care product packaging, aluminum foil exhibits excellent barrier properties that minimize water evaporation and ingredient loss, concentrating the product a consumer pays for - thereby providing better efficacy.

Finally, in addition to the above advantages, 6-micron aluminum foil is light and compact making containers or bags more manageable at the transport or storage level. Additionally, both 6-micron and 9-micron aluminum foils provide excellent printability which can elevate the packaging quality and provide more visually appealing packaging solutions.

(4) Other packaging uses

Besides the above main applications, 1235 O 6-micron aluminum foil is also utilized in tobacco packaging, electronic component packaging, etc. In tobacco packaging, it is used for the cigarette box lining that restricts humidity with the tobacco. This restricted humidity helps prevent the tobacco from becoming damp, which not only preserves the flavour of the tobacco but also provides some light-blocking property.

In electronic component packaging, some properties of 1235 O 6-micron aluminum foil provide some shielding that will limit the impact of electromagnetic interference on its electronic components, as well as providing performance stability to its electronic components. As with the packaging of precision instruments, 1235 O 6-micron may be used as moisture-proof, dust-proof, and protective packaging.

HTMM Aluminum Foil Factory: Professional Customization of 1235 O Soft Packing Aluminum Foil

HTMM Aluminum Foil Factory is a professional manufacturer of aluminum foil products. HTMM has rich experience and technical advantages in the production and customization of 1235 O soft packing aluminum foil, especially 6 micron aluminum foil.

HTMM Aluminum Foil Factory has good production equipment and production processes to ensure the quality of aluminum products. During the whole production process. Only from raw material procurement to factory inspection, there are strict requirements on quality. For example, in the raw material procurement, the factory only provides aluminum foil made in 1235 aluminum alloy ingots with good quality to guarantee the overall basic performance of the aluminum foil. In the product production process, the factory will use advanced rolling process includes structural features and control of rolling parameters, to control the aluminum foil thickness to use precise 6 micron, made sure the aluminum foil maintains the same thickness. During the product quality assurance, the factory has dedicated annealing equipment, and after the aluminum foil production is completed, it will be subject to strict annealing treatment, usually the aluminum foil can only achieve O-temper properties, when the O-temper properties are flexible and ductile.

HTMM Aluminum Foil Factory knows that customers have different packaging requirements, so it provides customized services. Customers are able to customize the 1235 O 6-micron aluminum foil products at various widths and lengths depending on the characteristics of their products and packaging requirements. The factory is also able to provide additional services, such as surface treatment and composite pre-treatment, depending upon a customer's special needs, giving customers a "One-stop" packaging material service. During the course of services HTMM Aluminum Foil Factory will communicate and cooperate with customers, so that it promptly understands changes in customer needs and offers professional technical support and technical recommendations to ensure customers are provided with the most suitable aluminum foil products.

We believe that in the future with the continued development of the packaging industry, that it will be a broader application prospect for 1235 0 6-micron aluminum foil and that HTMM Aluminum Foil Factory will continue to provide customers with better quality products and services.

.jpg)