There are many alloys to choose from for aluminum foil, and the common ones are 8011, 8079, 1235, 3003, etc. Among these aluminum foil alloys, 8011 heavy-duty aluminum foil is particularly prominent and popular. Its excellent durability, heat resistance and versatility make it the first choice for industrial and commercial use. So, what are the characteristics of heavy-duty aluminum foil and why is it so popular? Let's understand and discuss it together.

What is 8011 heavy-duty aluminum foil and why is it so popular for industrial and commercial use?

In fact, 8011 heavy-duty aluminum foil is a kind of aluminum foil specially produced for industrial and commercial use. Its own strength, durability and tear resistance are tailored for industrial and commercial use. The difference from standard aluminum foil is that 8011 heavy-duty aluminum foil is thicker and more durable, suitable for both industries. Among them, its excellent barrier properties, heat resistance and flexibility make it widely used in food packaging, insulation, cooking and various manufacturing processes, and its wide range of applications is amazing.

Main advantages of 8011 heavy-duty aluminum foil

High strength: resistant to puncture and tearing, it performs well for heavy or sharp object wrapping.

Good thermal conductivity: even heat distribution, excellent heat resistance and thermal conductivity, suitable for baking and grilling applications.

Corrosion resistance: good corrosion resistance can prevent contamination and maintain product integrity, and it is very durable as a food packaging material.

Moisture and light protection: Food has very strict requirements for moisture and light protection. 8011 giant aluminum foil has the above advantages and is very suitable for this industry.

Environmentally friendly and recyclable: The material is environmentally friendly and recyclable, which is conducive to sustainable development.

| Feature | Benefit |

| High Tensile Strength | Prevents breakage during handling |

| Non-Toxic | Safe for food contact and medical use |

| Flexible & Malleable | Easily molded around objects |

| Chemical Resistant | Protects against contamination |

| Temperature Resistant | Withstands extreme heat and cold |

Why is heavy duty aluminum foil used in industrial applications?

1. Why is it suitable for high temperature cooking?

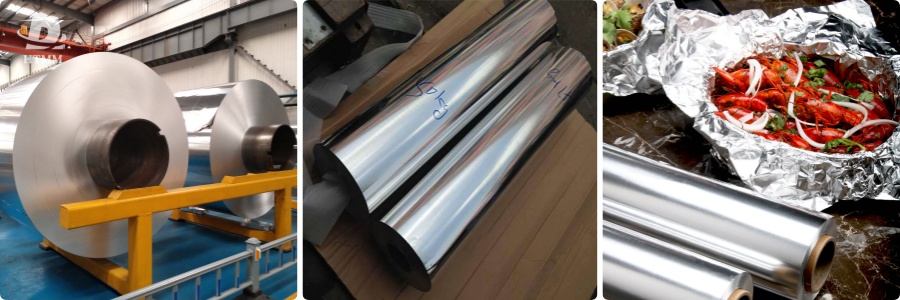

One of the most obvious features of 8011 heavy duty aluminum foil in commercial kitchens and industrial applications is the ability to withstand high temperatures, and it does this very well. One of the features of 8011 heavy duty aluminum foil is that it allows food to be heated evenly, can well protect ovens and grills from grease buildup, and is very convenient to use and throw away. Unlike ordinary aluminum foil, heavy duty aluminum foil is not easy to tear at high temperatures, which is particularly popular in the baking industry.

Advantages:

Withstands temperatures up to 600°F.

Locks in moisture in food while cooking and prevents drying out.

Protects cooking containers and reduces cleaning work for cooking utensils.

How does it enhance food packaging and preservation?

The inherent moisture resistance of 8011 heavy duty aluminum foil can act as a good barrier and easily extend the shelf life of perishable foods. Commercial food manufacturers use 8011 heavy duty aluminum foil to keep food fresh, prevent contamination and extend shelf life.

Common Uses:

Wrapping meat and dairy products,

Seal frozen foods.

Packaging ready-to-eat foods.

Why is it the best choice for insulation and HVAC applications?

Industrial grade heavy duty aluminum foil is often used for insulation and related applications due to its high reflectivity and heat resistance. It can be used as a protective barrier layer in buildings, which can be a good way to reduce energy costs and improve efficiency.

Advantages:

Reflects up to 97% of heat.

Moisture barrier, keeping buildings dry.

Can be used in ductwork for HVAC systems.

What is the difference between regular aluminum foil and commercial aluminum foil?

| Feature | Regular Aluminum Foil | Commercial Aluminum Foil |

| Thickness | 0.00063 inches | 0.0012 inches or more |

| Durability | Tears easily | Resistant to punctures and tears |

| Heat Resistance | Up to 400°F | Up to 600°F |

| Usage | Household applications | Industrial, commercial, and heavy-duty tasks |

Ordinary aluminum foil can meet daily use, while commercial aluminum foil is designed to meet the use of larger industries such as commercial kitchens and food processing. Generally, it is used in larger quantities and is more durable.

How does small roll aluminum foil compare to large roll aluminum foil?

This needs to be distinguished from various aspects of small roll aluminum foil and large roll aluminum foil. For companies that need aluminum foil of different sizes, small roll aluminum foil provides convenience and ease of use. And large roll aluminum foil provides durability and economy. One is very flexible and used for small applications, and the other is durable and used for large applications.

Comparison:

Small roll aluminum foil: very suitable for small applications such as home kitchens, restaurants and take-out services.

Large roll aluminum foil: very suitable and durable in industrial environments that require mass production.

Where can I buy high-quality 8011 heavy-duty aluminum foil?

When purchasing 8011 heavy-duty aluminum foil, you need to find high-quality aluminum foil, reliable suppliers, and can provide you with a large number of stable applications.

The global catering and industrial industries are booming, and the demand for high-performance materials for cooking, packaging and insulation has also increased significantly. 8011 heavy-duty aluminum foil has become the material of choice for these manufacturers due to its durability, heat resistance and versatility. Whether it is used in commercial kitchens, HVAC applications or industrial packaging, excellent performance has become the most popular material choice for all manufacturers. By choosing a reputable supplier such as HTMM, you can be sure to purchase materials that will make you extremely satisfied.