The superior recycling rate of aluminum foil versus plastic packaging becomes an important competitive differentiator. Used aluminum foil can become new foil through infinite recycling without quality degradation. In contrast, most recycled plastics downcycle into lower applications each reuse cycle. With amplified recycling education and policies, consumers increasingly seek post-consumer aluminum foil in favor of plastic.

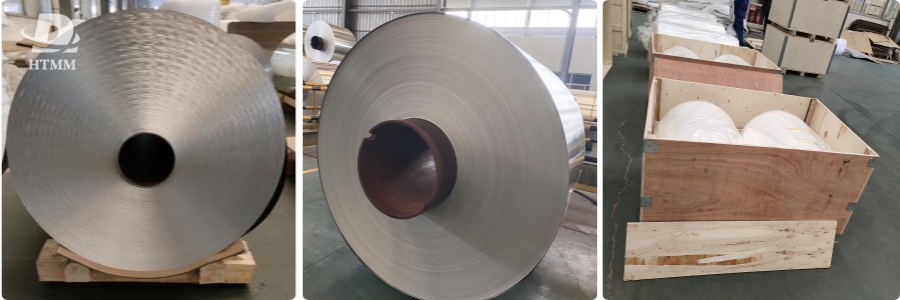

Aluminum Foil Flexible Packaging Specifications

To meet the needs of the growing Serbian pet food market, aluminum foil rolls and the flexible packaging made from it must comply with key material properties and specifications:

Aluminum Foil Thickness: The most commonly used gauges for pet food pouches and bags range between 15-50 microns. Foils as thin as 6-8 microns can also be used for lidding applications through downgauging.

Barrier Properties: The foil must have high moisture and gas barrier capabilities to protect contents for 9-15 months under room temperature storage conditions. Oxygen transmission rates should be below 1 cc/m2/day.

Printability: The foil surface must suit primary and reverse-side printing technologies like flexography to allow branding and on-pack communication. Smooth surfaces without creases or cracks are essential.

Formability: The flexible foil rolls must deform easily into pouches, bags or other forms during horizontal or vertical form-fill-seal production runs. Ductility and stretch properties are important measures.

Recyclability: The foil composition should consist of minimum 90% aluminum to facilitate recycling through established post-consumer collection streams.

Food-Grade Compliance: The final packaging must conform to European and Serbian food contact material regulations for indirect food use.

Durability: The packaging should withstand distribution impacts and pressures without damage, leakage or compromised barrier for the targeted 9-month shelf life.

With these key technical requirements, aluminum foil emerges as a top choice for flexible pouches and retortable trays often used in Serbian pet food sector. Its ease of forming, printing and stress-crack resistance prove invaluable for automating production lines catering to both wet and dry formulations.

Aluminum Foil: The Future of Flexible Packaging

Major Serbian pet food brands have already transitioned a portion of their product lines to aluminum foil flexible packaging or plan to do so in the near future. The material’s outstanding barrier and recyclability give these forward-looking companies competitive differentiators. With local recycling infrastructure bolstering aluminum recovery rates, brands gain assurance that post-use packaging will stay within the circular economy.

Key flexible packaging converters also expressed confidence that downward aluminum foil thickness trends would continue. Based on forecasted availability of 8-micron foils in the next 3-5 years, completely plastic-free pouch options may become feasible for certain applications. Dry food pouches already embrace ultra-thin foils down to 10 microns successfully.

Meanwhile, further advances in printing resolution now bring once-impossible designs like special effects and micro-textures to aluminum foil flexible packaging. These value-added embellishments elevate brands without compromising sustainability. Novel post-print enhancements using techniques such as laser-scoring allow creating easy-open features as well.

By pioneering standardized aluminum foil packaging variants, early adopting pet food companies aim to future-proof their sustainable portfolios for the long run. Considering Serbian consumers’ enthusiastic embrace of pets and eco-values, it appears aluminum foil flexible packaging has a bright future in this region and beyond. When combined with efficient collection programs, the inherent recyclability of aluminum foil rolls can truly nourish both people and planet.