As you’ve already learned, flexible packaging comprises a barrier to the outside environment.

In fact, at the heart of any effective flexible packaging solution is the need for strong barrier protection. When it comes to such a vital task, flexible packaging aluminum foil, which protects against foam, moisture, and light like no other material, is the preferred option. But the barrier performance is determined by the thickness of the foil.

High-quality flexible packaging aluminum foil is usually produced in thicknesses ranging from 20 microns to 50 microns (1 micron = 1/1000 mm), which act as a barrier against a wide range of environmental factors. This greater thickness create a stronger barrier, making it extremely difficult for harmful elements to penetrate, ensuring the freshness, quality, and safety of your products.

Thinner flexible packaging aluminum foil is usually 6 to 15 microns thick. Due to its production process, it is more expensive, but may sacrifice overall barrier properties. Therefore, it needs to be combined with other materials to achieve better storage and preservation functions.

A Balance With Flexibility but Firm Guidelines

Flexibility vs. Rigidity: Flexible packaging solutions must strike a balance between flexibility and rigidity. This balance is largely determined by the thickness of the foil and affects the final functionality and aesthetics of the package.

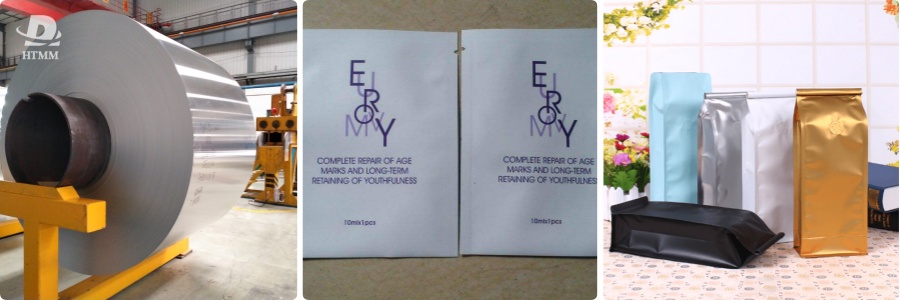

More flexible, thinner foils are ideal for complex packaging designs and can be combined with other flexible materials, stand-up pouches, retort pouches, laminations, and more. This versatility enhances existing packaging formats to appeal to consumers and differentiate your brand in the market.

On the other hand, thicker foils, while offering the best barrier protection, may be less ductile, which can limit packaging formats and design options. Therefore, this is critical for all brands interested in expanding flexible packaging and offering new, aesthetically pleasing solutions.

Reinforcing Structural Integrity and Rigidity

The thickness of the aluminum foil used must also take into account the required integrity and rigidity of the container, which can vary depending on the application and the nature of the packed contents.

Another consideration is that heavier or fragile items may require thicker aluminum foil in the package to ensure the necessary rigidity and to avoid deformation or damage during handling and shipping. On the other hand, a lighter or not-so-fragile product can be sufficiently maintained for optimum cost efficiency by utilizing thinner aluminium foil without losing performance.

Furthermore, different packaging applications, including stand up pouches, retort processing, welding/gussets, etc., may require certain thickness specifications, to maintain the shape and performance of the package during its life span.

Choosing the right aluminum foil thickness is a crucial decision to its ability and health that could define its future in the flexible packaging industry. As a premier manufacturer of premium aluminium foil solutions, we know how integral this process of choosing the right thickness is and have determined the best thickness ranges for different flexible packaging use cases.

Stand-Up Pouches: Your Lightweight Option

For stand up pouches, the ideal thickness of aluminium foil is generally between 12 and 20 microns. This thinner foil provides the optimal combination of flexibility and structural strength that allows for the development of a new type of pouch that attracts attention and sells on the shelf.

Aluminum foil thickness of 12 to 20 micron boasts great flexibility which helps in easily moulding into plastic films and other flexible packaging materials for a better fit. This versatility allows for the creation of complex, visually appealing pouch shapes that enhance product presentation and brand identity.

Preventing Damage to Packaged Goods | Retort Pouches

The use of a thicker gauge aluminum foil provides excellent barrier protection and structural integrity for rigors of heat processing for retort pouch applications. The thickness for retort pouches is usually 20-35 micron.

By having a greater thickness, it creates a more impermeable barrier with regards to oxygen, moisture, and light that can damage the packaged contents. This enhanced barrier performance is essential to preserve freshness, quality, and safety of the contents, particularly critical for sensitive products such as food and pharmaceuticals.

Moreover, the thicker aluminum foil serves the dual purpose of giving the required rigidity to the pouch, allowing it to withstand the high temperatures and pressures typically employed in retort processing — a critical factor to ensure that the pouch retains both structural and operational integrity throughout the product lifecycle.

Strength: The Power of Laminated Structures in Packaging

Materials used for flexible packaging odesofthe stores are tumprinted to a variety of different colors, and then laminated with a thin layer of plastic. In such applications the thickness of the aluminum foil used may vary depending on the requirements and the configuration of the laminate.

Aluminum foil (6-12 microns) can be a good option for lightweight and economical laminates. This low gauge foil easily integrates with plastic films and other flexible materials for new brilliant and eye catching packaging designs.

Conversely, 12-20 microns are the general preferred thickness of aluminum foil used for laminates that require more barrier resistance, as well as structural integrity. That larger dimension increases the strength of the overall barrier performance, while its rigidity helps maintaining the structural integrity of the laminate.

Blister Packaging | Essential Protection with Adaptability

Aluminum foil thickness selection presents special challenges for blister packaging, one of the most widely used formats for packaging small, individual items. In this context rebalancing flexibility and structural rigidity is crucial.

The most preferred aluminum foil thickness for blister packaging is below 20-35 microns. This extra thickness adds just enough stiffness to support the blister cavity's shape and form, preventing the packaged product from falling out. The foil maintains sufficient flexibility to be able to shape and seal the blister pack accurately.

The thicker aluminum foil also plays a role in the overall barrier properties of the blister packaging, ensuring the packaged contents are protected from external factors and maintaining product integrity.

Finding the Right Balance Between Cost and Performance

As with all packaging decisions, the cost-effectiveness of the solution is another key consideration. The thicker aluminum foil provides better barrier protection and structural integrity; however, this type of foil generally costs more. Alternatively, thinner foil is available and may be more affordable, especially for high volume applications.

The solution lies in optimizing the cost versus performance: the ideal aluminum foil thickness for your use case will provide the balance between performance, protection, and value that works best for you and your customers.

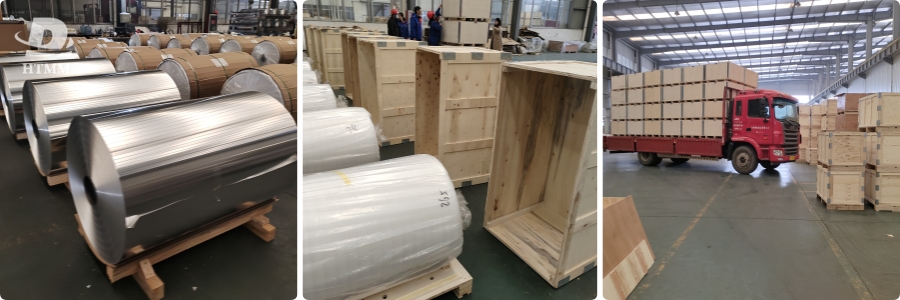

When selecting aluminum foil thickness to help obtain success in your flexible packaging, one should choose wisely amongst the following: barrier protection, flexibility and rigidity, structural integrity and cost-effectiveness. To help in this process, HTMM high quality flexible packaging foil manufacturer,our team of packaging experts is equipped to help you leverage aluminum foil to suit your flexible packaging needs.