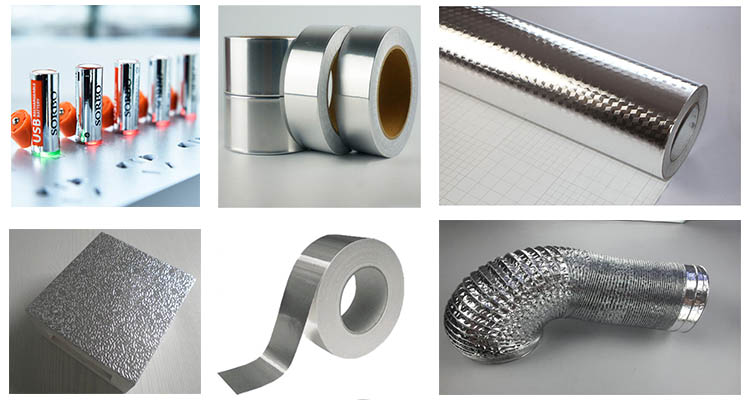

Wholesale Aluminum Foil In Jumbo Roll

Wholesale Aluminum Foil In Jumbo Roll

The aluminum foil coated with a hydrophilic organic coating on the surface of the aluminum foil can be hydrophilic, so this kind of aluminum foil coated with a special coating is called a hydrophilic aluminum foil

Hydrophilic aluminum foil material After degreasing, washing, and drying, the aluminum foil is coated with special coatings on its two surfaces. After drying and cooling, it becomes a very hydrophilic and corrosion-resistant material. Hydrophilic aluminum foil can make air conditioners Extend the service life of 5-10 years. Hydrophilic aluminum foil rolls increase corrosion resistance. Condensate on the accumulation surface of the anti-mold and odorless heat exchange fins is evenly distributed on the surface, and will not cause accumulation and blockage between the heat exchange fins due to the formation of water droplets. Affect the heat exchange conditions, thereby increasing the heat exchange rate

Non-hydrophilic aluminum foil has serious defects. The biggest problem is that the condensed water generated during cooling will adhere to the aluminum foil and form a water bridge, causing blockage between the fins, affecting ventilation, reducing heat exchange efficiency, and reducing the air conditioner’s efficiency. Energy efficiency ratio, thus more power consumption.

In fact, consumers only need to sprinkle a glass of water to identify whether it is hydrophilic aluminum foil. The water cannot flow away and looks watery. The water bridge phenomenon is the use of non-hydrophilic aluminum foil.

Generally, non-hydrophilic aluminum foil is used for single-cooling machines, and hydrophilic aluminum foil is mostly used for heating and cooling machines.

The production process of hydrophilic aluminum foil:

Uncoiling→Pretreatment→Surface roll coating (first roll coating→first drying→second roll coating→second drying)→coiling

The function of pretreatment: mainly to enhance the bonding force between the coating and the aluminum foil.

The function of the coating: The coating has the function of increasing the hydrophilicity and anti-corrosion of the product.

For products with higher performance requirements, if the primary coating fails to meet the required indicators, a secondary coating is required. Generally speaking, single-coated products have both hydrophilic function and corrosion resistance in the primary coating. For double-coated products, the first coating has a corrosion resistance effect, and the second coating has a hydrophilic effect.

Learn more about Aluminium Foil Used For Wrapping Food