Specification

Besides the quality of the products offered by HTMM, there are many advantages that come with working with HTMM; among these are great customer service! With a team that consists of knowledgeable sales and technical experts, the HTMM Aluminum Foil Factory provides customers with a complete experience by helping the customer understand what kind of product will work best for them, along with providing support once the customer has made a purchase.

Details include:

| Alloy |

8011/8006 |

| Temper |

O (Soft) |

| Thickness |

9 – 20 microns |

| Width |

30cm (customizable upon request) |

| Length per Roll |

5m – 300m |

| Core ID |

30mm / 38mm / 76mm |

| Surface Finish |

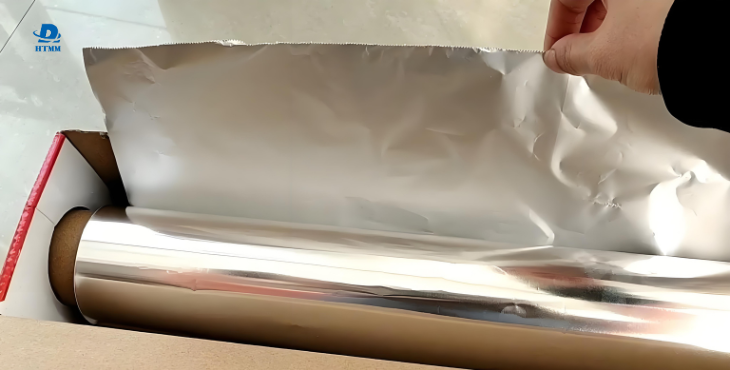

One side bright, one side matte |

| Packaging |

Boxed or shrink-wrapped with cutting blade |

| MOQ |

1000 rolls |

| Customization Service |

Logo printing, packaging design, core material |

| Application |

Catering, baking, food wrapping, take-away |

450mm x 75m Catering foil's lightweight range (0.012mm - 0.015mm) has great flexibility and cost savings associated with using that thickness of caterer foil to wrap small single wraps and medium-sized plates when covering a dish or keeping a dish warm/hot. Therefore, wrapping individual items in foil, and/or using foil to cover leftover food will protect them from bacteria while keeping their warmth/heat inside the plastic container. The lightweight nature of this type of foil will reduce fatigue for the kitchen staff during peak service times as the 75m roll is easily handled and stored.

The heavy-duty 0.020mm to 0.025mm thickness category of catering foil is designed for use with the 450mm x 75m caterer's foil. The added thickness gives this foil, stronger and more durable characteristics than the regular 0.020mm - 0.025mm foil and make it usable for more arduous applications such as Roasting, Baking and Grilling. During the baking process, the heavy-duty foil is able to withstand high heat without tearing or melting and therefore act as an effective barrier, holding juices and flavours. Grilling with the heavy-duty foil provides protection to delicate foods such as Fish and certain Vegetables that otherwise would fall through the grill grate as well as taking on the Flavour of the grill. In many cases, heavy-duty foil can be reused after being thoroughly cleaned, therefore providing a more sustainable option for catering Businesses seeking to reduce Waste.

The range of thicknesses from 0.016mm to 0.019mm is an extremely versatile middle range thickness that can be used for many different types of catering functions. It provides strength enough to wrap larger dishes or to cover large baking trays while providing an excellent degree of flexibility for wrapping irregularly shaped foods. This thickness of foil is a very popular choice among caterers because it provides the ability to have a single roll of foil for all their individual needs, meaning caterers are not required to stock multiple varieties of foil.

In the food preparation stage, foil is used very broadly for preparing and marinating ingredients. Caterers will often combine the marinades with the meat, poultry, or fish and wrap them in the foil so the marinade flavour will penetrate the food. The 450mm width of the foil is very helpful in this technique since it allows caterers to wrap large-sized cuts of meat, like roasts and turkey, without overlapping multiple pieces of foil. The length of 75 metres means that it provides plenty of foil to work with for the larger quantity of ingredients that are often needed for catering, such as weddings, corporate meetings, or festivals.

Foil is an excellent option for many types of cooking due to its ability to withstand incredibly high temperatures, along with its excellent barrier properties. The type of foil that is used for roasting and baking is called heavy-duty foil, while lightweight foil is typically for steaming food.

A lot of catering companies will make foil packets (also called foil dinners) when they are preparing food for an event. Foil packets consist of protein, vegetables, and seasoning together in one packet. The foil packets are placed in either a baking pan or on a grill for cooking, so by making each of the packets separately, catering companies can give their customers their meals more quickly, with individual portions, and without needing any extra time for cooking. Foil 450mm wide is especially helpful in creating larger foil packets that contain several servings of a meal. It reduces the overall amount of foil that is used, while also reducing the time it takes to cook and serve meals at events.

Comparison Aspect 450mm Width Catering Foil (75m Length) :

Coverage Capacity Can cover large dishes (e.g., 12-inch baking trays, full-size platters) in one piece without overlapping.

300mm Width Catering Foil (75m Length):

Requires 2-3 pieces of foil to cover large dishes, leading to overlapping and potential gaps.

As shown in the table, the primary benefit of the 450mm width is its capacity to manage large-scale catering projects more effectively while minimizing waste and labor expenditures and increasing its versatility. For caterers serving large numbers of people regularly or who often cater to events where the size of individual food products requires multiple levels of catering equipment, the 450mm x 75m catering foil rolls offer a better price point and a more efficient way to accomplish this.

If you are looking for a high-quality source of 450mm x 75m catering foil, look no further than HTMM Aluminum Foil Factory. With many years of experience in the production of aluminum foils for the food service industry, HTMM has developed a reputation as a reliable and innovative manufacturer of catering aluminum foil. The factory produces 450mm x 75m catering foil in every thickness offered in the industry (0.012mm to 0.025mm), allowing caterers a wide variety from which to choose the most appropriate for their catering requirements.

HTMM’s commitment to providing premium quality aluminum is demonstrated at every point in the process of producing aluminum foil. The aluminum foil is manufactured using virgin, high-purity aluminum ingots (99.7% pure aluminum) as raw materials to guarantee the product is free from all contaminants and is suitable for use with food products.

The production line utilizes state-of-the-art rolling and annealing equipment to provide consistent and uniform thickness and smooth surface area of the foil, maximising flexibility and longer life for the final product; Within its operations, HTMM employs an extensive quality control system, including comprehensive testing (aerospace) of every batch of aluminum foil to ensure that each sheet meets the required specifications for strength, heat resistance and compliance with FDA/Safe Food standards.

Because of the HTMM commitment to quality is backed by certification from internationally recognized organizations including ISO 9001 (Quality Management System) and FDA (Food and Drug Administration), HTMM's aluminum foil products are well positioned to compete successfully in Year 2021 and beyond.

HTMM is able to provide custom foil rolling solutions for their clients in addition to its 450MM x 75 Metre (450mm x75m) catering foil, which is a standard product line. Catering businesses may require specific types of foil for their menus, cooking methods, or brands; as such HTMM offers a variety of customisation options to meet these unique needs. Dimensions such as width (from 100mm to 1000mm), length (from 10m to 200m), thickness (from 0.008mm to 0.05mm) and surface finish (shiny or matte) can be tailored to suit individual customer requirements.

HTMM can also create custom printed foil rolls for customers to provide their customers with their logo, brand name, advertisements, etc., on the outside of their foil product. This will further help promote the business name, as well as give the customer a more professional image regarding the product.