Alloy 1235: The highest purity

1235 aluminum alloy is known for its exceptional purity, with a minimum aluminum content of 99.35%. This iron achieves a purity level through a process that thoroughly cleans it of impurities such as silicon and copper. The result is not only high performance but also good corrosion resistance, making it ideal for a variety of packaging applications.

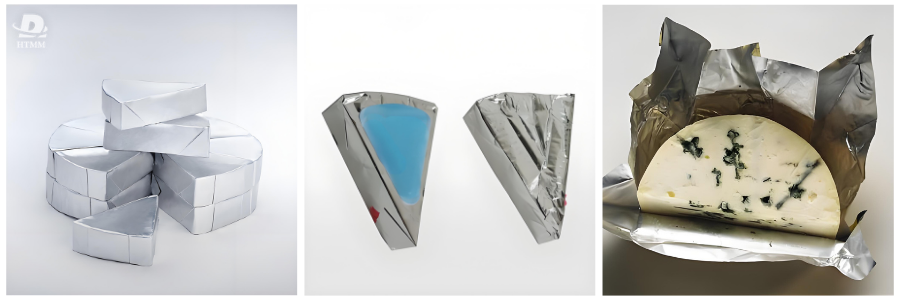

One of the main advantages of 1235 aluminum foil for flexible packaging is its good resistance. small pieces; Its ability to separate air and water makes it an important component in packaging solutions for a wide variety of food and beverage products. From solid confectionery products to sensitive pharmaceutical products; Alloy 1235 makes the equipment cool, ensures safety and tolerance. Good quality packaging also applies to personal care product packaging where maintaining product integrity is important.

In addition to its excellent resistance, Alloy 1235 is an attractive and attractive product. Print at the highest resolution to create beautiful graphics. This brand's combination of exceptional flexibility and anti-bacterial properties makes it a popular choice for flexible packaging solutions. Food manufacturers in industries such as snacks and coffee use Alloy 1235 to create aesthetic and functional packaging that enhances the customer experience.

Alloy 8011: A versatile workhorse

Although the cleanliness and resistance of alloy 1235 is excellent, 8011 aluminum foil for flexible packaging offers many advantages to meet the needs of flexible packaging. Aluminum foil thickness Available in aluminum content from 98.5% to 99.2%, Alloy 8011 balances cost and performance, making it a versatile choice for a variety of applications.

One of the unique features of alloy 8011 is its excellent composition. You can easily create soaps or tiles to create complex and interesting packaging designs. Vertical Pouches This feature is especially useful when creating flow wraps and other flexible packaging types that appeal to consumers. Food and beverage manufacturers and the personal care industry are adopting alloy 8011 to transform ordinary packaging into beautiful and functional products.

Apart from the process. Alloy 8011 also has exceptional strength and toughness, making it a great choice for applications that require increased strength and tear resistance. This feature tool is very useful for packing sensitive products (such as electronics and even some food products).

In addition, the malleability of alloy 8011 makes it suitable for many turning and molding processes. Produced in print, Aluminum foil width convertible and digital versions. This combination ensures consistent, high-quality results, allowing brands to present their products in bright packaging.

Flexible packaging changes

The emergence of alloy 1235 and alloy 8011 in the flexible packaging industry follows changes in consumer preferences. Various factors contribute to this, including the issue of sustainability and technological progress.

One of the most important trends shaping the flexible packaging landscape is the increasing demand for healthy consumption and low weight. Today's consumers want transparency. Recyclers are looking for packaging solutions, and flexible aluminum packaging has proven to be a good choice to meet these needs. Heavy and durable 1235 and 8011 alloys provide product protection and availability.

.jpg)