3003 H24 container foil excels in terms of strength. Compared with H18, aluminum foil in H18 condition has higher strength, but its toughness is relatively low, so it is prone to rupture due to stress concentration in the process of lunch box stamping, which affects the yield of the lunch box. The disposable 3003-H24 aluminium foil for food containers, after specific processing, has good strength and excellent toughness at the same time. This enables it to withstand the complex stamping process during the production of lunchboxes, which greatly reduces the scrap rate of the product and saves production costs for lunchbox manufacturers.

Compared to the H22 condition, 3003 H24 aluminum foil is stronger and better able to support the shape of the lunchbox. In practice, lunchboxes may be subjected to a variety of external forces, and lunchboxes made from H22 foils may be slightly weaker and prone to deformation. Meal boxes made of 3003 H24 meal box foil, on the other hand, maintain their shape and ensure the safety of food during storage and transportation.

In the process of meal box manufacturing, processing performance is crucial, disposable 3003-H24 aluminium foil for food containers has good processing performance, easier to process than H18, H18 due to its higher hardness, when processing needs more punching pressure, the requirements for stamping equipment is higher, and the wear and tear of molds in the process is more serious. 3003 H24 container foil effectively improve this problem, it can be processed under relatively low punching pressure, not only to reduce the load on equipment and extend the service life of molds, but also to improve production efficiency. It can be processed under relatively low punching pressure, which not only reduces the load of the equipment, extends the service life of the mold, but also improves the production efficiency.

Compared to H22, 3003 H24 aluminum foil are easier to control in terms of dimensional accuracy during processing. Lunch box manufacturing requires strict dimensional accuracy, H22 may be processed due to the characteristics of the material, resulting in relatively large deviations in size, while 3003 H24 lunch box foil, with its stable performance, can ensure the accuracy of the dimensions of the lunch box, so that the production of lunch boxes with better consistency and improve product quality.

In the process of lunch box stamping and forming, a large friction will be generated between the aluminum foil and the mold. Without oiling, this friction may lead to scratches, folds and other defects on the surface of the aluminum foil, which seriously affects the appearance and quality of the lunch box. The oiled 3003 H24 lunch box foil can form a lubricating film between the foil and the die, effectively reducing friction. This enables the aluminum foil to flow more smoothly during the stamping process and fill all corners of the die, thus producing meal boxes with smooth surfaces and regular shapes. At the same time, oiling also reduces the risk of aluminum foil rupture due to excessive friction, further improving the yield of the lunch box.

The die is an important piece of equipment in the production of lunch boxes, and its service life has a direct impact on production costs. 3003 H24 lunch box foils are oiled to form a protective film on the surface of the die, which reduces direct contact between the foil and the die and wear and tear. During the stamping process, the unoiled aluminum foil may scratch the surface of the die, and long-term use will lead to wear and deformation of the die surface, affecting the precision and service life of the die. The oiled lunch box foil can effectively reduce this kind of wear and prolong the replacement cycle of the mold, which saves the cost of the mold for the enterprise and improves the production efficiency.

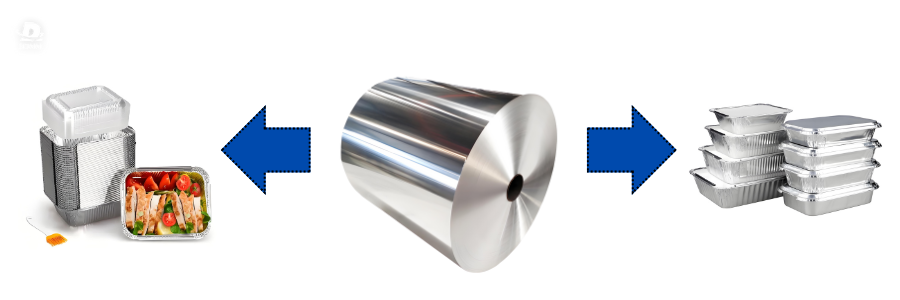

HTMM Aluminum Foil Factory has an excellent reputation in the industry as a company specializing in the production of food grade aluminum foil. With advanced production equipment and strict quality control system, HTMM Aluminum Foil Factory is committed to providing customers with high quality ungreased and greased lunch box foils. For the production of 3003 H24 greased lunch box foil, HTMM Aluminum Foil Factory strictly controls the selection of raw materials from the beginning. The use of high quality 3003 aluminum alloy ensures that the foil has a good performance base. In the production process, the advanced oiling process is adopted, which can precisely control the amount of oiling and ensure the uniformity of oiling to meet the needs of different customers for oiled lunch box foils.

The 3003-H24 aluminium lubricated container foil produced by HTMM factory has clean surface, no oil, bright lines and other inclusions, safe and hygienic products, and high elongation. Whether it is used for airline lunch boxes, takeaway lunch boxes, or lunch boxes used for home cooking, the product demonstrates outstanding performance.

Safety in food packaging is a top priority, and HTMM's 3003-H24 aluminium lubricated container foil are made with food-grade lubricants that have been carefully screened to meet international food safety standards. This oil has good chemical stability and does not react with food or migrate harmful substances into the food, thus ensuring food safety and hygiene. At the same time, the oiling can also isolate air and moisture to a certain extent, preventing the aluminum foil lunch boxes from rusting, which further protects the quality of food during storage and transportation.

With professional production capacity and persistent pursuit of quality, HTMM Aluminum Foil Factory provides high quality 3003 H24 oiled lunch box foil products to the market, and is a reliable partner of lunch box manufacturers. Choosing 3003 H24 greased lunch box foil and HTMM Aluminum Foil Factory is to inject strong quality power into the business of lunch box manufacturing.