Specification

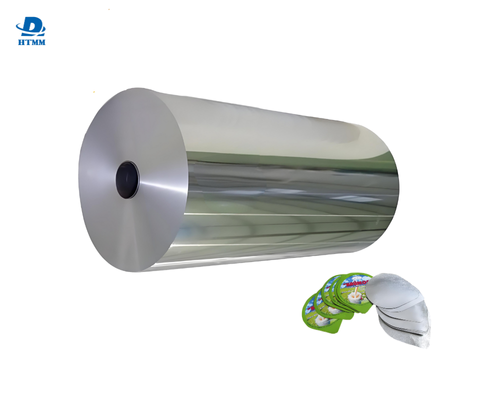

Our foil lids can be made with proprietary coating formulations to match yogurt types and storage conditions; moreover, our foil lids provide outstanding resistance to acidic dairy environments, consistent performance across filling/sealing packages, and reliable tamper-evident features to increase consumer confidence—all while complying with food safe standards and sustainability, through the optimization of material usage and recyclability.

Details include:

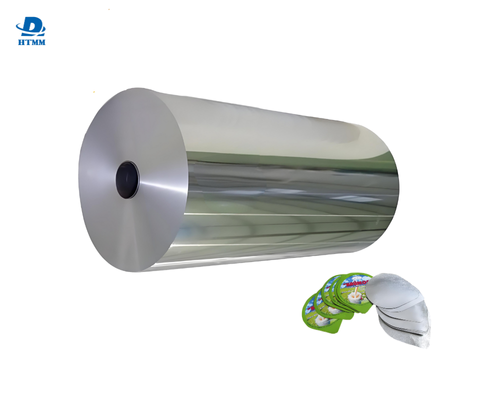

| Alloy |

8011, 1235 |

| Temper |

O (Soft) |

| Thickness |

8–25 microns |

| Width |

200mm–1600mm |

| Roll Core ID |

76mm (3 inch) or 152mm (6 inch) |

| Surface |

One side bright, one side matte |

| MOQ |

3 tons per size |

| Packaging |

Standard export wooden case |

| Customization |

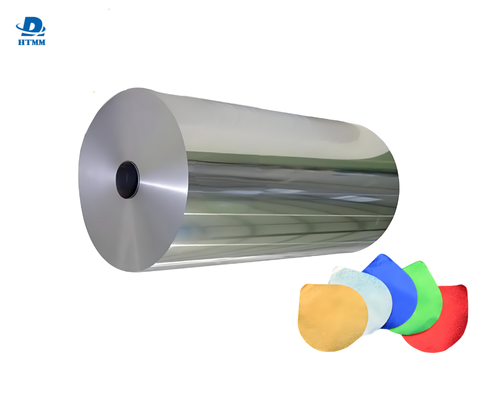

Thickness, width, logo, and packaging can be customized |

| Application |

Household kitchen foil rolls, catering foil, baking foil, wrapping foil |

Bestselling CountriesOur aluminum foil lids for yogurt packaging have garnered a strong foothold in the European dairy markets, particularly in Germany, France, and the Netherlands, due to the sophisticated nature of their dairy industries and passion for quality products. The North American market, including the US and Canada, has shown increasing interest in the foil lids for both conventional and specialty yogurt products. Japan, South Korea, and China, which have higher levels of dairy consumption and modernization methods, are also showing signs of growing demand for foil lids. The Middle East, comprising markets such as Saudi Arabia and the UAE, recognizes the value of foil lids due to their performance in challenging climate conditions. Dairy manufacturers in Australia and New Zealand regularly specify our foil lids to meet their export-quality criteria. Emerging dairy markets in Southeast Asia and Latin America are quickly recognizing the foil lids' value proposition as they expand their packaging needs and quality expectations.

FAQWhat distinguishes your aluminum foil lids in the yogurt packaging space? Our lids are designed specifically for dairy requirements, featuring unique barrier properties and coatings to maximize seal integrity, easy peeling, and printing, all engineered for high-speed filling processes within dairy applications.

Can you offer lids used for different yogurt variants/cup materials? Yes. We make custom coating formulations to suit various yogurt types and cup construction materials. These include options like PP, PS, PLA, and other polymer types, with specific adhesion and peel properties.

How do you maintain consistency in seal performance? We conduct stringent quality assurance/controls processes which include coating uniformity testing, seal strength testing, and compatibility studies with cup construction for consistency.

What printing capabilities do you have available for brand customization? We offer high-definition rotogravure printing with up to 8 colors, suitable color matches and color-matching systems, and food-safe inks that last throughout the product lifecycle.

Are you able to create sustainable foil lid options?Of course, we can provide solutions in recyclable materials, with less material, compatible with sustainable packaging systems, while retaining the barrier properties.

What is your lead time for customized foil lid orders?The standard lead time is 4-6 weeks depending on customizations, but we can set up urgent production invoicing, stock programs for standard specs, and even flip the lead-time on occasion.

What is your process for handling foil lid quality issues?If it is a matter of quality, we can respond to you with the utmost sense of urgency. We will investigate the technical issue, replace the material at no charge, and provide corrective actions to prevent the issue from reoccurring.

Do you have the ability to match lid specifications that I already have?Our technical group can reverse engineer some existing lid specifications and often time provide you with performance improvements or cost reductions.

What type of technical support do you offer based on the filling line?Our technical support ranges everywhere from machine parameter recommendations, troubleshooting, and on-site technical service to support the performance on your filling lines.

Will you offer me a sample quantity for testing purposes?We provide complete sample kits with different specifications to test the production process, along with rapid shipping, so you are not delaying your development schedule.