Requirements for Dairy Liquid Aseptic Packaging Materials

In the Swiss market, dairy products are mainly packaged in aseptic packaging for sale. The key requirements for aseptic packaging materials are as follows:

Oxygen, moisture and light barrier performance. Dairy products are easily oxidized and lose freshness. The packaging material needs to have good oxygen, moisture and light barrier performance to protect the quality of dairy products.

Heat resistance. The packaging material needs to have high heat resistance to withstand high-temperature aseptic filling and sealing processes.

Flexibility and formability. The packaging material needs to have good flexibility and formability to be easily formed into various package structures.

Non-toxic and tasteless. The packaging material should not contaminate the taste and quality of dairy products, and will not produce toxic substances during high-temperature sterilization.

Affordable price. As a daily consumable, the packaging cost of dairy products cannot be too high.

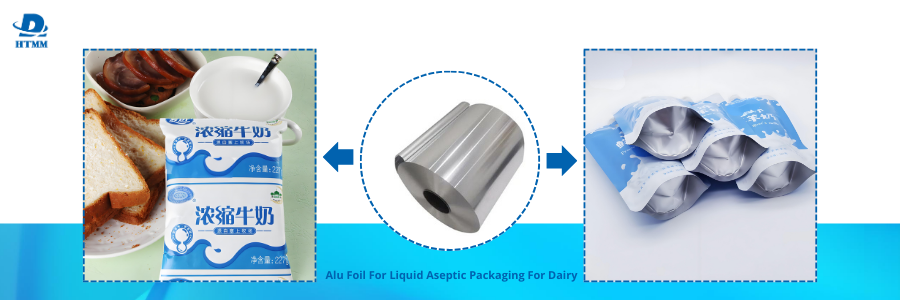

The Advantages of 6.3 Micron Aluminum Foil for Dairy Liquid Aseptic Packaging

Aluminum foil is widely used in dairy liquid aseptic packaging due to its excellent barrier properties, heat resistance, non-toxicity and affordable price. Among various aluminum foils, 6.3 micron aluminum foil has significant advantages:

Aluminum Alloy and Laminated Foil for Dairy Liquid Packaging

Aluminum Alloy

For dairy liquid aseptic packaging, the commonly used aluminum alloy is 8011 aluminum alloy. 8011 aluminum alloy has the following advantages:

Excellent flexibility. 8011 aluminum alloy has good plasticity and can be easily formed, meeting the requirements of complex package forming.

Outstanding barrier performance. 8011 aluminum foil has excellent oxygen and moisture barrier performance, which can well prevent dairy products from oxidation and moisture loss.

High heat resistance. 8011 aluminum alloy has high melting point up to 640°C, ensuring no loss of barrier performance after high-temperature sterilization.

Good sealing property. The surface of 8011 aluminum foil is easy to seal, which is beneficial to the packaging filling.

Affordable price. 8011 aluminum alloy has a price advantage compared to high-purity aluminum materials.

However, the 8011 aluminum alloy foil also has some shortcomings. For example, its gas barrier performance is slightly inferior to high-purity aluminum foil.

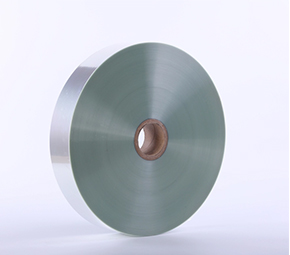

Laminated Foil

To overcome the shortcomings of 8011 aluminum alloy foil and further improve barrier performance, laminated aluminum foil composed of 8011 aluminum alloy and plastic film is widely used.

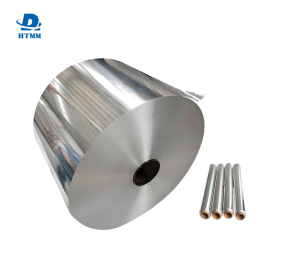

HTMM is a leading aluminum foil supplier in China. Its laminated aluminum foil adopts 6.3 micron 8011 aluminum as the barrier layer, and high-barrier plastic film such as PET, EVOH or SiOx as the strengthening layer. Some advantages are as follows:

Superior barrier performance. The plastic film strengthening layer can significantly improve the foil's gas barrier performance. Oxygen transmission rate is as low as 0.01cc/m2·day, meeting the requirements of aseptic packaging for dairy products with a shelf life of 6 months.

Enhanced mechanical properties. Plastic film provides supporting effect, effectively improving the foil's folding endurance, burst strength and other mechanical properties.

Good heat sealing property. The plastic film surface has excellent heat sealing performance, ensuring reliable and easy packaging sealing.

Affordable price. Compared with composite barrier materials, laminated foil has a price advantage.

.png)

Therefore, laminated aluminum foil is more suitable for dairy liquid aseptic packaging. HTMM's 6.3 micron laminated aluminum foil, with its outstanding barrier performance, mechanical properties and heat sealing property, can fully meet the packaging requirements of dairy products.