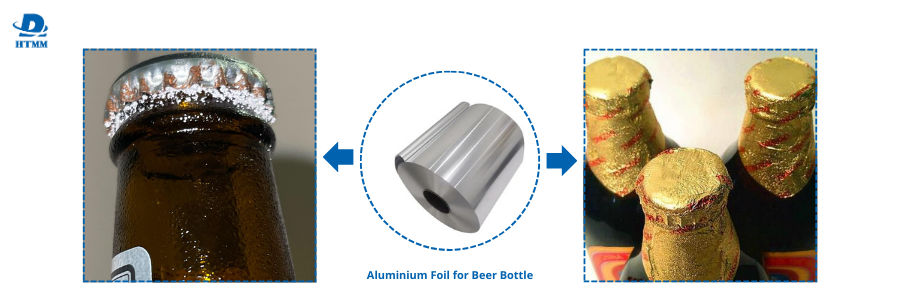

One of the primary reasons for the foil neck is to protect the beer from light exposure. Most beers, especially pale lagers and wheat beers, can be negatively affected if exposed to direct sunlight or artificial lighting. Harmful light can cause undesirable chemical reactions in the beer, altering the taste and aroma over time. Beer Bottle Neck Foils The foil acts as an effective barrier, blocking out nearly all light from penetrating the bottle. This prevents lightstruck flavors from developing during storage and transport before the beer is consumed. Without the foil, the beer quality could deteriorate rapidly on the shelf or while sitting in someone's refrigerator. Brewers rely on the foil to ensure each bottle maintains the same great flavor as when it was bottled at the brewery.

In addition to protecting against light, the foil neck also helps maintain carbonation levels in bottled beer. Beer naturally contains dissolved carbon dioxide, which gives it bubbles and liveliness. However, carbon dioxide can gradually escape from an unsealed bottle through the small opening at the neck. Foil Seal For Bottles The rate of loss depends on factors like temperature, but even at cool temperatures carbonation will fade over weeks without a tight seal. The thin aluminum foil adheres smoothly to create an effective seal that is nearly impermeable to gas. This seal allows brewers to bottle condition their beers, relying on residual yeast and priming sugar to naturally carbonate in the sealed bottle over time. The foil plays a vital role in trapping the carbonation inside the bottle from the moment it is sealed to when the consumer opens it.

Aside from technical functions, the foil serves practical purposes that benefit both brewers and consumers. From a production standpoint, foil provides a simple and low-cost way to seal bottles during bottling runs that can fill thousands of bottles per hour. It allows for high-speed capping lines without complicated mechanisms. And because the foil is thin and pliable, it causes minimal slowdown when moving bottles through the packaging process. For consumers, the foil acts as a freshness indicator that gives insight into how a beer has been handled from the brewery to the point of purchase. An intact foil tells the buyer that the contents remain protected and carbonated. It also provides a satisfying experience, with the satisfying "pop" of breaking the seal adding to enjoyment of that first drink. The tactile removal of the foil gives customers confidence in the quality and freshness of what's inside the bottle.

Of course, aluminum foil serves other roles beyond beer packaging as well. Here at our company, we produce foil for numerous applications in food packaging, household products, industrial uses, and more. However, beer bottle foil remains a particularly notable use that highlights foil's unique combination of protective qualities. The impermeable yet flexible nature of aluminum makes it uniquely suited to form an effective gas and light barrier directly on bottle openings. This allows brewers to ensure their products maintain freshness and carbonation during distribution. As a leading manufacturer with extensive experience and technical knowledge, we're proud to supply foil that plays a key part in bringing high-quality craft beers to consumers worldwide. Aluminum foil safeguards the flavors brewers craft and the enjoyment drinkers experience from their first sip. Its role on beer bottles is a prime example of how such a simple material can make a meaningful difference.

In summary, the aluminum foil covering found on many beer bottles serves several important technical functions that benefit both brewers and drinkers. It forms an effective barrier against light and oxygen, safeguarding a beer's delicate flavors and aromas as well as its carbonation level from the moment it is packaged to when the consumer opens it. The consistent, high-quality seal provided by foil allows brewers to confidently distribute their products worldwide while maintaining freshness. And for customers, the tactile "pop" of breaking the foil seal adds to the enjoyment and experience of their first drink. Here at our aluminum foil manufacturing company, we take pride in supplying foil for this notable application that plays such a key role in the beer industry worldwide. Its protective properties make foil uniquely suited to preserve beer quality from brewery to glass.