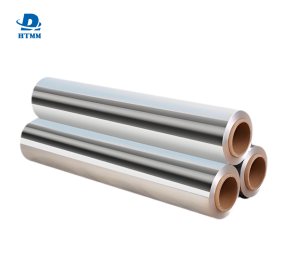

The commonly selected laminated foil for flexible packaging can choose alloys: 8011, 8079, 1235. Among them, 8079 flexible packaging aluminum foil is often used for chocolate packaging, snack packaging, and condiment packaging. 8011 flexible packaging aluminum foil is often used for various household packaging, such as skin care product packaging, etc., and 1235 aluminum foil is often used for industrial packaging, such as cable packaging, making aluminum foil tape, and used as a moisture barrier.

Understanding the advantages of these aluminum foils for flexible packaging can help you choose the most suitable flexible packaging aluminum foil for your use.

Why choose laminated aluminum foil for packaging?

Laminated aluminum foil, also known as flexible packaging aluminum foil, is often chosen for packaging because of the characteristics of the packaging industry. Packaging industry manufacturers need this material to have excellent performance, such as durability, safety, high efficiency in transportation, and convenient logo printing. The emergence of flexible packaging aluminum foil fully meets these requirements of packaging manufacturers. Therefore, many increasingly wise packaging manufacturers will choose flexible packaging aluminum foil for lamination.

Advantages of 8079-O aluminum foil for flexible packaging

8079-O flexible packaging aluminum foil is a high-performance laminated material that is used for food packaging applications in various industries. Please see the table below for its characteristics:

| Property | Specification |

| Thickness Range | 6-200 microns |

| Customizable Width | Available as per requirement |

| Applications | Pharmaceutical, food, and industrial packaging |

Main advantages of 8079-O aluminum foil:

High flexibility: It can package your food with soft materials!

Excellent barrier protection: It protects your products like a warrior to avoid spoilage.

Strong puncture resistance: It can improve packaging durability, making your packaging more durable and tough.

Advantages of 8011-O aluminum foil for flexible packaging

8011-O aluminum foil is a well-balanced alloy and is the most intimate choice for food packaging manufacturers and beverage packaging manufacturers.

Property Specification

Thickness Range 6-200 microns

Customizable Width Available as per requirement

Applications Food, pharmaceutical, and household packaging

Main advantages of 8011-O aluminum foil:

Are you worried about problems during heat sealing? With 8011 aluminum foil, you can seal well.

Are you worried about the performance of 8011? With 8011 aluminum foil, it has excellent corrosion resistance and perfectly protects your products.

Are you worried about cost-effectiveness? Don't worry, 8011 aluminum foil is lightweight and easy to transport, giving you greater economic benefits.

Advantages of 1235-O aluminum foil for flexible packaging

Flexible packaging aluminum foil 1235 O is mainly used in industrial applications such as cable foil, tape foil and moisture-proof packaging, and is extremely durable.

| Property | Specification |

| Thickness Range | 6-200 microns |

| Customizable Width | Available as per requirement |

| Applications | Industrial packaging, electrical components, and insulation |

Main advantages of 1235-O aluminum foil:

The difference between 1235 aluminum foil and 8079 aluminum foil is that one is more suitable for food contact and the other is more suitable for industrial use. Because 1235 aluminum foil has excellent moisture and chemical resistance, no material can surpass and replace it in protecting industrial parts.

1235 aluminum foil has excellent plasticity and is suitable for high-speed packaging processes. It will never be a drag.

1235 aluminum foil has reliable insulation performance. No material can match it in electrical and thermal applications.

The role of aluminum foil flexible packaging in sustainable packaging

The global packaging industry is developing rapidly, and the demand for aluminum foil is gradually increasing. Flexible packaging aluminum foil plays a vital role in the entire packaging industry.

Its gratifying recyclability makes this high-performance laminated aluminum foil recyclable and reduces waste.

Its most reliable lightweight can well reduce the amount of material used.

In short, flexible packaging aluminum foil is still an indispensable and extremely important packaging material choice in modern packaging solutions. The advantages of laminated aluminum foil make it an indispensable product in various industries, from food and pharmaceuticals to industrial applications. Whether choosing 1235 O flexible packaging aluminum foil or 8011 or 8079 aluminum foil, packaging manufacturers can get the maximum economic benefits from its inherent excellent performance.