8079 alloy is an aluminium-manganese alloy that cannot be heat treated. It contains approximately 0.8-1.2% manganese as the main alloying element. Manganese improves the strength and formability of the foil during rolling and forming. Other trace elements include iron, silicon, copper, magnesium, chromium, zinc and titanium.

The lamination process applies a regular textured pattern to the surface of the foil. As the foil passes over engraved steel rollers under controlled pressure, a fine diamond pattern is imprinted on the metal. The pattern is symmetrical and extends evenly across the width of the foil. Light embossing does not affect the basic properties of the foil, but improves its handling and functionality. By increasing the surface area of the foil at a microscopic level, this pattern is able to retain a thin layer of lubricant. This improves smoothness and reduces noise during processing and use. The texture also improves printability of labels and graphic copies.

The lamination process prints a diamond or linear pattern on the surface of the foil. The foil is used to control the embossing pressure via an engraved steel roller. This increases the surface area without compromising key material properties. The soft texture retains a thin layer of lubricant. Multiple rollers ensure uniform patterning across the entire width. Automatic motors maintain tight process parameters. Strict protocols ensure consistent lamination quality.

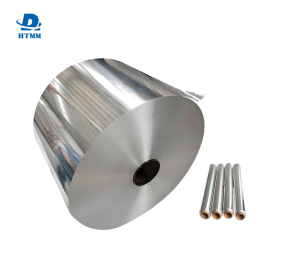

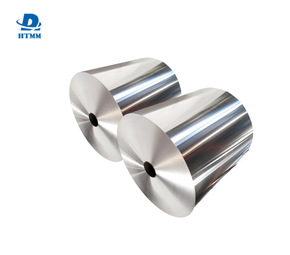

HTMM Aluminium is a leading manufacturer of high quality aluminum foil. We specialize in large rolls of Bare Aluminium Foil 8079 alloy foil. The foil passes through multiple pressure rollers in a continuous process. Precision motors maintain strict speed, gap width and engraving reproduction parameters. This ensures uniform lamination across the entire width of the foil. We follow strict quality protocols to ensure consistency in pattern geometry and oil application. A variety of pattern styles can be applied to meet different customer needs.

The soft lamination surface offers multiple benefits. Its non-stick texture prevents blocking and sticking when winding or stacking. Laminated Aluminum Foil Supplier. A microscopic layer of oil improves sliding and separation capabilities. It also dampens sound vibrations when crumpled or disturbed compared to standard foils. Excellent printability stems from the pattern's secure grip on the ink. Most importantly, the key properties of the 8079 alloy, such as strength and flexibility, are not altered.

Our laminated foils are used in a wide range of applications. Food packaging, such as meat packaging, benefits from a barrier and a clear view of the contents. Pharmaceutical blister foils enhance the moisture and airtightness of pharmaceuticals. Home cooking and storage packaging provide a durable non-stick surface. Electrical components take advantage of its insulating and shielding capabilities. Capacitor and battery applications use the foil as a current collector. It can also be used as a printed substrate and easily enters the container.

We start with high-purity aluminum ingots containing the 8079 alloy component. The ingots are hot rolled into coils or parent coils with precise thicknesses, such as 6μm. Hot rolling deforms and squeezes the metal through heavy rollers at high temperatures and pressures. The foil is then annealed and cold rolled to improve its properties. Aluminium Foil For Lamination 6-9 Micron. Final processing includes cleaning, lubrication, and slitting. Our standard foils are soft annealed for optimal flexibility. All equipment is manufactured to strict quality and environmental standards. Regular testing ensures consistent product specifications.

Laminated Alloy 8079 foil is well suited for many markets due to its balanced combination of properties. Common uses include food packaging, pharmaceutical blister packaging, aluminum beverage bottles, appliance parts, heat shields, and more. Aluminum foil protects contents while providing visibility. It prevents the ingress of moisture, gas, or contaminants. Other applications utilize its insulating or current collecting capabilities. Its barrier properties and performance make it an advantageous material across industries.