The Wide Range of Applications for 1235 Aluminum Foil in Flexible Packaging

Flexible Packaging Revolutionizes the Tobacco Industry

The tobacco industry has undergone tremendous changes in recent years. Traditional hard packaging is being replaced by more environmentally friendly flexible packaging. Aluminum foil plays a vital role in the new generation of flexible packaging for cigarettes. Its barrier properties and versatility provide an optimal solution for manufacturers seeking alternatives to plastic overwrap and paperboard.

1235 Aluminum Foil: Ideal for Cigarette Packaging

The aluminum alloy commonly chosen for cigarette foil is 1235. With a purity of 99.3%, 1235 aluminum offers exceptional formability and barrier performance at an attractive price point. Its ultra-thin gauges around 0.006mm provide a barrier to moisture, gas, and light while maintaining flexibility during high-speed production lines. The low emissivity of 1235 aluminum foil also helps block infrared rays that could otherwise degrade product quality.

The Emirates Leads Flexible Packaging Adoption

One region at the forefront of flexible packaging adoption in the tobacco industry is the United Arab Emirates. Home to a world-class manufacturing infrastructure and duty-free status, the UAE attracts major international cigarette brands. Local producers like XX and YY have upgraded their packaging from laminated paperboard to laminated aluminum foil substrates. Not only does the new flexible packaging reduce material costs, but it also enhances shelf appeal, functionality, and environmental profile.

1235 Aluminum Foil Technical Specifications

Let's examine the key technical specifications of 1235-O aluminum foil in 0.006mm thickness:

Alloy: 1235 aluminum

Gauge: 0.006mm +/- 5%

Width: 1220mm +/- 1mm

Length: Standard log width is up to 5000m

Surface: Mill finish on both sides

Embossing: Can be lightly embossed for texture or branding

Roll cores: 76mm interior diameter cardboard or plastic cores

1235 Aluminum Foil Production Process

1235 aluminum ingot is first heated to 640°C and hot rolled into long coils. The hot rolled coils then undergo a intermediate annealing process to refine the grain structure. Next, the coils are cold rolled in multiple passes to reduce thickness down to the ultra-thin gauges required for cigarette foil like 0.006mm. The cold rolled foil coils are then tension leveled to remove thickness variations before winding onto rolls. A light lubricant may be applied to the foil surface to aid further processing.

Lamination Provides Protection and Functionality

On its own, raw 1235 aluminum foil provides an effective moisture and gas barrier but lacks other required properties for end-use applications. Therefore, foil substrates undergo further processing like laminating or coating. In cigarette packaging, a polymer film like biaxially oriented polypropylene (BOPP) or casting vinylidene chloride (PVDC) is typically adhesion laminated to one or both sides of the aluminum foil. This integration imparts needed characteristics such as printability, puncture resistance, sealing performance and recyclability. It also protects the foil's bare aluminum surface.

Emirates Tobacco Extends Sustainability Efforts

A prominent example is Emirates Tobacco, the largest listed company in the UAE. Seeking to further minimize its environmental footprint, Emirates Tobacco recently transitioned several top-selling cigarette brands from paperboard to laminated aluminum foil packaging. The new flexible packaging requires less raw material per pack versus rigid boxes, resulting in an estimated annual reduction of 6000 tons of paperboard. Additionally, the ultra-thin 1235 aluminum foil substrates are fully recyclable alongside associated polymer films post-consumer. The sustainability gains have positioned Emirates Tobacco as an industry leader while adhering to the nation's climate goals.

Extended Shelf Life from Superior Barrier

Aluminum foil's high barrier properties are a core advantage over alternative substrates for flexible packaging. Independent laboratory tests have confirmed 1235-O aluminum foil laminated structures maintain extremely low moisture and oxygen ingress even after 6 months of ambient shelf conditions. In contrast, paperboard or uncoated plastic films often start showing degradation after just a few weeks on shelf due to permeability to moisture, gases and infrared light. The extended shelf life afforded by 1235 aluminum foil translates directly to reduced costs from inventory shrinkage or out-of-stocks for consumer product companies and retailers.

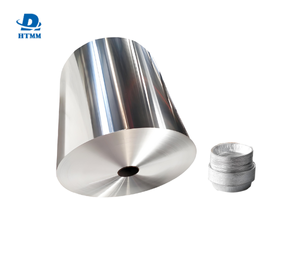

Global Supplier with Robust Manufacturing

As a global supplier of 1235 aluminum foil, HTMM operates world-scale rolling facilities accredited with the highest quality and environmental standards. With an annual production capacity over 300,000 tons, HTMM can reliably meet even the largest order volumes for 1220mm wide jumbo reels up to 5000m in length. Multiple regional conversion centers further process foil rolls through slitting, sheeting and laminating operations to fulfill diverse customer specifications. Backed by a strong R&D team, HTMM also develops customized product solutions to open new segments for aluminum foil.

In summary, 1235 aluminum foil laminated structures have emerged as the packaging material of choice for the tobacco industry’s transition to more sustainable flexible formats. Key players like Emirates Tobacco recognize both the enhanced functionality and reduced environmental impact versus legacy paperboard or plastic overwrap systems. HTMM’s leadership in 1235 aluminum foil and related value-added laminates have made it a trusted partner supporting this paradigm shift. Looking ahead, flexible packaging accelerated by aluminum foil is poised for expanded usage across multiple industries throughout the MEA markets.