Specification

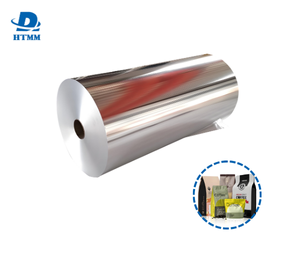

Aluminum foil raw materials are crucial to the packaging industry because they provide reliable, flexible, and environmentally friendly solutions for a wide range of applications.

Aluminum foil is the material of choice for manufacturers worldwide due to its superior barrier properties, lightweight design, and customizable nature.

HTMM's goal is to provide high-quality aluminum foil, customized to your specific needs. Please contact us for more information.

Details include:

| Type |

Flexible packaging aluminum foil |

| Grade |

Food Grade |

| Alloy |

1235 8011 8079 |

| Temper |

O |

| Thickness |

0.0055MM-0.03MM |

| Width |

200MM-1600MM |

| Surface |

One side bright, One side matt |

| Packaging |

Free Fumigated wooden box |

| Applicable Laminated Types |

PET/AL/PE, BOPP/AL/PE, PAPER/AL/PE, NY/AL/PE |

| Application |

To be used for food packaging/ Cigarette Packaging after lamination,Snack packaging, coffee pouches, dairy wraps, beverage sachets, pharmaceutical packaging |

Frequently Asked Questions (FAQ)

1.What distinguishes 8011 from other food-grade foils such as 1235 or 8079? In general, 8011 foil provides a better mix between strength and deep-drawing formability than the softer 1235. It is perfect for container applications that need many draws since it has better pinhole resistance than certain other alloys.

2.What thickness is ideal for a typical food container? The depth and application of the container determine this. 0.05 to 0.06 mm is typical for shallow trays (such as those used for pastries). For improved stiffness, 0.07mm to 0.09mm is advised for deeper containers (such as

those used for prepared meals).

3.Is it possible to use 8011 container foil in microwave ovens? In most cases, no. Aluminum foil reflects microwaves and can result in arcing, or sparks, which can harm the oven and start a fire. It is made to work with both convection and traditional ovens.

4.Is it possible to print on the foil? Yes, in response. Premium, food-safe inks can be used to print on and treat the surface. This is perfect for nutritional data, cooking directions, and branding.

5.How long is your lead time? The lead time for standard requirements is normally 15 to 20 days following order confirmation. Depending on the complexity, customized orders could take anywhere from 25 to 30 days.

6.Do you offer samples? Yes, we do offer complimentary samples. Customers simply have to cover the cost of shipping. This enables you to evaluate the appropriateness and quality before to making a large purchase.

7.Which certifications are attached to your products? Our 8011 container foil is certified by ISO 9001 and ISO 22000 and meets FDA (USA) and EC 1935/2004 (EU) standards for materials that come into contact with food.

8.How is the foil wrapped to guard against deterioration in transit? The answer is that coils are put on wooden pallets after being firmly covered in stretch film and strengthened with steel straps and waterproof paper. This guarantees that they are shielded from physical harm, dust, and moisture.

9.What is your 8011 foil's pinhole standard? Our premium-grade 8011 foil ensures a superior barrier because of its extremely low pinhole count, which usually meets industry specifications of fewer than a particular number per square meter (e.g., < 50 pinholes/m² for a specific thickness).

10.Can you make foil that is coated to make it easier to release? Answer: Definitely. For packaging sticky goods, we can cover one side of the foil with food-grade silicone or other non-stick coatings.

11.What distinguishes the H18 temper from the O temper? The soft, very formable O temper (annealed) is perfect for deep-drawing intricate containers. The totally hard H18 temper is ideal for shallow trays or lids where rigidity is essential since it offers high strength and stiffness with limited formability.

12.How can you guarantee that each batch is of the same quality? To ensure batch-to-batch consistency, we use a strict Quality Control system that includes online thickness gauging, spectrometric analysis of alloys, and routine mechanical property testing (elongation, tensile strength).

13.What terms do you have for payments? We provide a variety of payment options, most often T/T (Telegraphic Transfer), with a 30% down payment and the remaining 70% due upon a copy of the bill of lading. For long-standing customers, an L/C (Letter of Credit) is also appropriate.

14. Is it possible to cook with aluminum foil? Indeed, because aluminum foil can tolerate high temperatures well, it is frequently used in cooking to line baking trays and wrap food.