Aluminum foil is used to make flexible packaging, which is the most suitable choice for the flexible packaging industry. If you are looking for reliable 8079 laminated foil and purchase it in large specifications at factory prices, the following content can help you.

Why is 8079 aluminum foil an ideal choice for flexible packaging?

8079 aluminum foil itself has excellent barrier properties, including excellent moisture, gas and light resistance. It has an unshakable position in the food, pharmaceutical and cosmetic packaging industries.

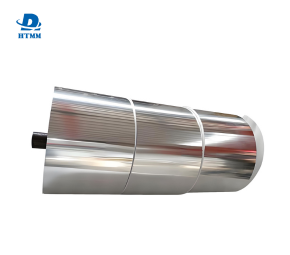

Among them, the flexibility and strength of 8079 aluminum foil are used to make flexible packaging materials that can withstand various handling and storage conditions. In addition, it can provide a clean and flat surface, which is essential for applications that require strict contamination control.

How important is thickness to performance?

Aluminum foil is used to make flexible packaging, and the optimal thickness is 12 microns. 12 micron thick laminating foil is the standard choice for many applications. The advantages are as follows: 1. It achieves a perfect balance between protection and cost-effectiveness. 2. This thickness ensures that the aluminum foil is smoothly compounded during lamination, sealing and molding processes.

After 12 micron 8079 aluminum foil is made into laminated foil, its mechanical properties, heat resistance and insulation are improved. Customers appreciate its advantages of maintaining good structure without adding volume.

What are the advantages of choosing laminated foil?

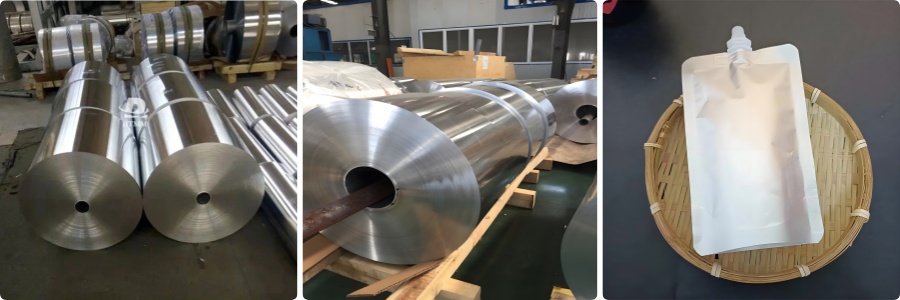

Laminated foil combines the barrier properties of aluminum with the strength of plastic or paper layers, thereby improving sealing, shelf life and printability. These good properties are particularly prominent in the food and pharmaceutical packaging industry, where this laminated foil helps prevent contamination and extend the shelf life of products.

Packaging that comes in direct contact with food cannot do without these properties, and 8079 laminated foil can safely meet these requirements, which can be regarded as the biggest advantage of this foil and the most important consideration for packaging manufacturers.

Using 8079 aluminum foil in a laminated structure can also reduce the weight of the package while increasing its protective properties. It is the most commonly selected packaging material for disposable pouches, small packages and blister packs.

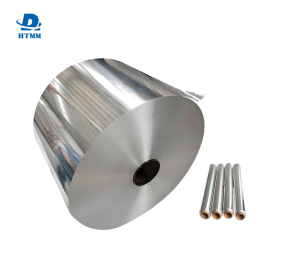

Why choose Factory price wholesale 8079 alloy aluminum foil jumbo roll for sale?

When buyers purchase flexible packaging materials, the first consideration is quality and price. When buyers purchase directly from manufacturers, they can wholesale 8079 alloy aluminum foil jumbo rolls at factory prices. The benefits are: lower unit costs and ensure better supply control.

In addition, purchasing large rolls of aluminum foil can also achieve greater customization of slitting, rewinding and laminating operations. Customers can adjust the size of the aluminum foil according to their exact machine needs, making it more conducive to your production needs.

How does customization improve supply chain efficiency?

Customized 12 micron 8079 aluminum foil can be customized in terms of width, thickness and surface treatment. The right packaging material will improve production efficiency, simplifying the production line and ensuring compatibility with downstream processes such as coating, printing or sealing.

In the process of using 8079 aluminum foil for flexible packaging, any deviation from the required specifications may lead to product loss or rework. So, the best way to solve this problem is customization.

Trustworthy suppliers always wholesale 8079 alloy aluminum foil jumbo rolls at factory prices and provide quality assurance. They also support customized orders, whether in width or thickness, to meet customer needs with the most accurate dimensions.

12 micron thick 8079 aluminum foil has become the first choice for laminated aluminum foil applications in flexible packaging due to its high-quality characteristics. These premium features are tailored for safety, hygiene and mechanical strength, which can bring the greatest economic value to all packaging production industries that require laminated foil. For buyers seeking long-term supply at the right cost, sourcing customized jumbo rolls directly from Chinese aluminum foil manufacturers is the most effective solution.