Specification

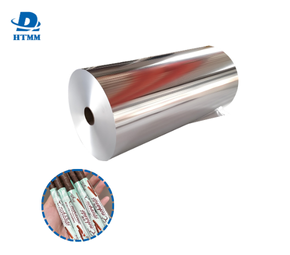

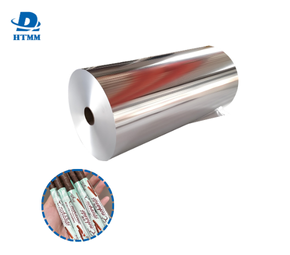

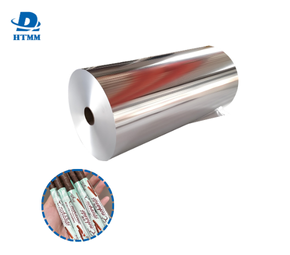

8079-O aluminum foil is the preferred barrier material for pharmaceutical blister packaging.

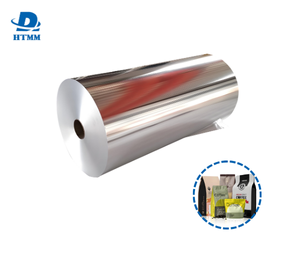

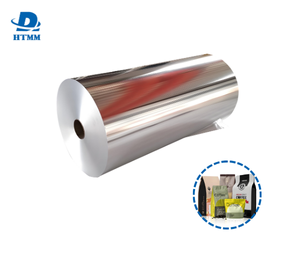

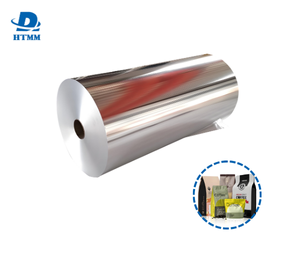

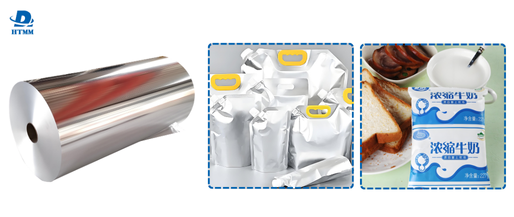

Its excellent barrier properties enable it to effectively maintain odor and freshness in flexible packaging products such as coffee and snacks (e.g., stand-up pouches).

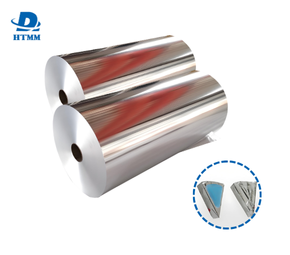

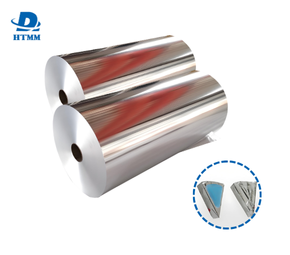

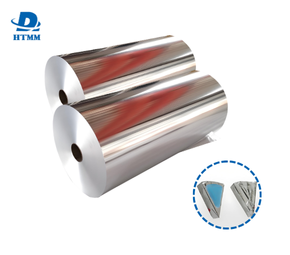

Liquid packaging composites used in dairy products and beverages require absolute integrity.

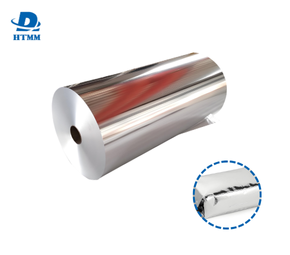

8079-O aluminum foil provides consistent quality for technical applications such as insulation materials and cable shielding.

Details include:

| Type |

8079 aluminum foil |

| Grade |

Food Grade |

| Alloy |

1235 8011 8079 |

| Temper |

O |

| Thickness |

0.0055MM-0.03MM |

| Width |

200MM-1600MM |

| Surface |

One side bright, One side matt |

| Packaging |

Free Fumigated wooden box |

| Applicable Laminated Types |

PET/AL/PE, BOPP/AL/PE, PAPER/AL/PE, NY/AL/PE |

| Application |

To be used for food packaging/ Cigarette Packaging after lamination,Snack packaging, coffee pouches, dairy wraps, beverage sachets, pharmaceutical packaging |

Top-Selling Countries/RegionsOur 8079-O aluminum foil rolls have maintained steady growth in the European market and earned a strong reputation.

Germany, France, and the UK are the main demand markets for pharmaceutical and high-end food packaging applications.

The North American market has also seen significant growth, primarily driven by the recognition of consistent quality in flexible packaging by the US and Canada.

The Asian market has also achieved robust growth and continues its upward momentum.

Countries such as Japan, South Korea, and India prioritize superior manufacturing processes and reliability.

The Middle Eastern market, including the UAE and Saudi Arabia, is experiencing increasing market acceptance due to the booming packaging industry.

Leveraging our extensive experience in manufacturing in Australia and New Zealand and our rigorous quality control, we have established a strong market position in these two countries.

We are further expanding our market share in emerging markets in Southeast Asia and Africa through strategic partnerships and the superior performance and value of our aluminum foil products.

FAQ:What distinguishes the 8079-O alloy from other aluminum alloys for flexible packaging applications? The 8079-O alloy offers an ideal combination of iron and silicon content, which results in increased strength and barrier properties as compared to other alloys, while offering superior formability with exceptionally few pinholes for enhanced reliability in demanding packaging applications.

Can your foil be used for pharmaceutical blister packaging? Yes, our 8079-O foil is produced in certified facilities and manufactured to pharmaceutical standards, with a controlled thickness and excellent forming characteristics to make perfect blisters while providing complete protection of the product.

What is theorder minimum for custom widths? There is no minimum order quantity for custom slit widths, but the order minimum is three tons, which may be split between specific specifications to meet your production needs while maintaining costs.

How consistent is the thickness of the foil across the jumbo rolls? We maintain a thickness tolerance of +/- 3% through a system of real-time monitoring, so you have outstanding consistency throughout every jumbo roll and across production runs.

What certifications does your 8079-O foil have? Our foil has FDA, EU and ISO certifications for food contact, and we maintain full traceability and documentation to meet international regulatory needs.

Do you supply foil with specialized surface treatments?Yes, we provide a number of surface treatments, including corona treatment and chemical priming, to increase lamination and printing adhesion to meet your application requirements.

What is the lead time for shipment of a container load?Typical lead times are in the 25-35 days range. Expedited options are available for urgent needs, where we ensure there is no supply gap for your production.

What is your price compared to a local company?Our initial price may be slightly higher, but our superior quality provides a better yield and fewer production concerns, which results in a lower total cost of ownership.

Do you provide technical support for processing issues?Our technical team provides comprehensive consulting support for web breaks, wrinkling and adhesion issues. We provide remote and site technical assistance.

What sustainable processes do you use?We utilize energy-neutral rolling technology, culminating with a water recycling system that encompasses production efficiency, sustainability and waste values and alternatives of foil that have recycled content.