Aluminum also provides an uninterupted barrier to light, gases, and moisture a key factor in food preservation. Furthermore, it is fully recyclable and contributes to global sustainability. Containers foil is widely used in airline food packaging,home cooking and a large chain of cake shops. It is suitable for both cold storage and oven heating, speeding up and simplifying food packaging, and eliminating the need for extra storage containers or packaging layers.

The Application of 3003 H24 Aluminum Foil in Food Container Production

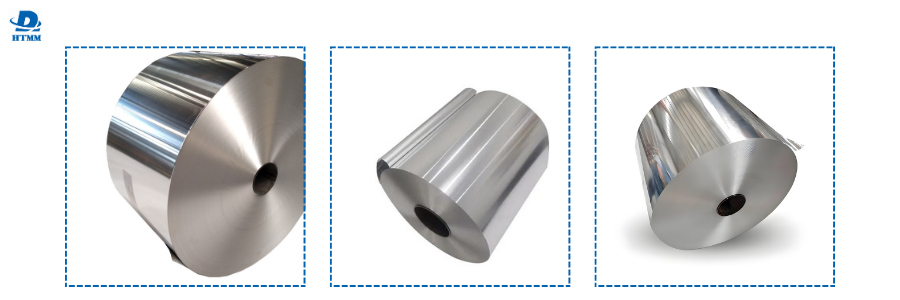

3003 H24 aluminum foil is one of the most commonly used materials for food packaging, it is a non-heat treatable aluminum, belongs to aluminum-manganese alloy, and is best suited for making various food containers. H24 aluminum foil is strain hardened and partially annealed, with a semi-hard state, which means it is strain hardened to 1/2 hard state for higher strength.

This special alloy is the raw material of choice for aluminum foil containers because it is non-toxic, safe for food handling, does not spoil, maintains food freshness and remains stable over the entire temperature range

Moreover, a lot of them choose aluminum foil as the metal raw material to make the containers lubricate alloy 3003. This type has a surface coating or lubricant to minimize friction during high-speed stamping required in mass production. It can avoid breaking or crease, improve the surface quality of final products, and increase production efficiency.

Selecting the Proper Thickness and Width for Your Application

| Application Type | Aluminum Foil Thickness |

| Self Service Containers | 0.03 – 0.05 mm |

| Medium-Strength Containers (e.g., lunch boxes, frozen meal trays) | 0.06 – 0.1 mm |

| Heavy-Duty Use (e.g., roasting pans, industrial containers) | 0.15 – 0.2 mm |

| Foil Width Considerations | 200 – 1,000 mm |

The thickness and breadth of the container foil selected in the container directly affect the performance and cost of the food containers. The usual thickness of 3003 H24 aluminum foil is 0.03-0.2mm. For instance:

Self Service: 0.03 – 0.05 mm Light weight food containers (dessert tray, take away lid)

Medium-strength containers (generally lunch boxes and frozen meal trays): 0.06 – 0.1mm

(for heavy intensive use kinds of use, e.g., roasting pans, industrial containers): 0.15 – 0.2 mm

Foil width is usually determined by the food container design and forming equipment. In typical production lines, aluminum foil with a width of between 200 and 1,000 mm is used. Manufacturers should work with their foil suppliers and/or equipment suppliers to make sure materials and equipment are specified together.

To maintain consistency in quality, we expect high quality aluminum foil for container 3003 H24 to be smooth, flat, free of pinholes and uniform thickness. A lubricated surface especially, is important for high-speed punching where you are using aluminum foil for container with lubricate alloy 3003 to maximize efficiency with production and minimize defects.

Benefits of Using Container Foil in the Food Industry

The ongoing acceptance of container foil in food applications continues to flourish for the many advantages:

Hygiene and Safety: Aluminum is sterile, non-toxic, and acceptable for direct food contact with all food.

Heat and Cold Resistance: Endures extreme heat to extreme cold or deep freeze without losing structural integrity or leaching any harmful chemicals.

Formable: Can be formed into different shapes without breaking, and you can bend it 90 degrees, especially container foil 3003 H24.

Environmental advantages: 100% recyclable without significant degradation of the recycled product.

Efficient Processing: There is little to be done in the conversion if container foil plate is use with lubricate alloy 3003 which can facilitate fast, smooth forming.

The application of 3003 H24 aluminum foil in real world situations

Below are a few examples of where high quality aluminum foil for container 3003 H24 might be used:

Airline catering trays: Require a lightweight but sturdy container that can withstand re-heating.

Baking Containers: Can tolerate high oven temperatures without melting or leaching any contaminants into food.

Ready-to-Eat Meal Trays: Can withstand the freezing and storing of food, as well as incorporating microwave heating.

BBQ and Takeaway Boxes: They allow for hot food to be transported, enables retaining hot temperature after sealing, but also assists in preventing any leaking.

When it comes to specific reliable, safe and better performing food packaging materials, container foil has no equal. 3003 H24 aluminum foil as a full developed material, has been ideal for the production of good quality food containers and is have lot of advantages in solid strength, reasonable formability and safe over all prosecutions. Makes for an ideal aluminum foil container raw material, as well as an additional enhanced aluminum foil for container with lubricate alloy 3003, facilitates good production by a final consumer fresh container product.

If your product involves frozen foods, catering food services, or food delivery services, you can be confident that using container aluminum foil for container 3003 H24, you are acquiring performance, quality and peace of mind.