One of the most important things that you should pay attention to is the material and thickness of the coating. Aluminum foil is often coated to provide oil and water resistance, heat resistance, adhesion, etc. Common coatings include polyethylene (PE), polypropylene (PP), silicon monoxide (SiO), and extruded aluminum. Polyethylene packaging is versatile and affordable for general food packaging. The PP coating provides better oil protection during cooking. CO2 fluids offer heat resistance up to 350°C, making them suitable for baking, food packaging and foil applications. Evaporated aluminum layers create a very thin barrier to heat application. In addition to the type of paint, the weight or thickness of the paint can also affect properties - heavier layers perform better but cost more. Evaluating your specific program needs will help determine the best coverage options.

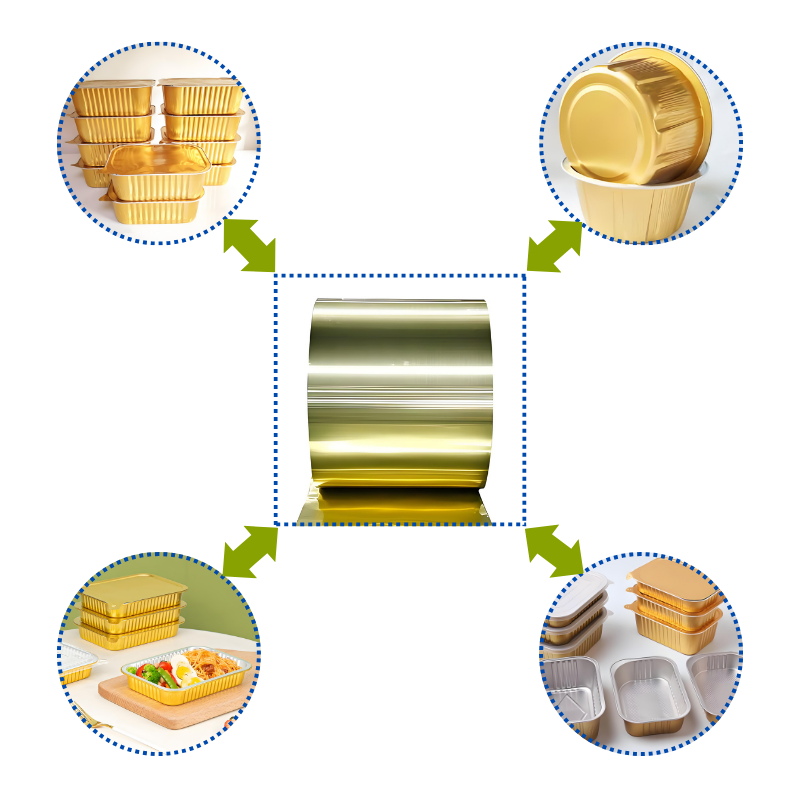

The intended end use of the chip is another key factor. Aluminum foil has a wide range of applications in food, industrial, household and other sectors. In the food industry, chip safety certification is essential, as is compliance with FDA regulations. Aluminum foil thickness Foils used for cooking or baking must withstand high temperatures. Industrial laminates may require strength, wear resistance or special surface properties. Internal laminates need proper design and economy. Consider using foil for food packaging, packaging, baking/cooking surfaces, insulation or other purposes. This shows which performance quality should be prioritized when choosing a chip.

Color and surface finish are also important properties depending on the type of foil used. For food packaging, foil is often clear and is available in standard silver or gold colors for added color. Industrial or household foil paints are available for identification purposes. Matte or textured finishes create a smooth or unmarked surface. Aluminum foil width On the other hand, it is a good idea to use a reflective surface to increase heat reflection. Choose colors and textures that match your desired visual impact or functional needs. Thin and clear films designed for food contact must use FDA-approved inks.

Another thing to consider is the width, thickness or gauge of the chip. Wide foils larger than 750 mm are more suitable for transformers, while foils smaller than 600 mm are used for commercial packaging. Choose a standard width to match your transformer or package lines. Film thickness is measured in microns - thicknesses greater than 20 microns provide stronger insulation, but cost more. When choosing the thickness of the chips, you need to consider the power you need and your budget. Thinner laminates offer fewer functions but produce less waste.

Finally, roll size or cutting capacity is an important practical consideration. Larger mother flowers reduce processing contamination compared to smaller logs. However, the large diameter requires enough space for handling and storage. Most food and household films have a width of 500-1000 mm and a weight of 50-300 kg. Industrial aluminum, available in widths over 1000 mm, has a high load capacity. Choose aluminum tubes that match the logistics and storage dimensions of your processing line.

Ultimately, several factors must be carefully considered to select the aluminum foil that best suits your needs. As a leading manufacturer, we offer a wide range of coated aluminum foils to meet all requirements. Contact us for custom solutions or technical advice on choosing the right aluminum foil. Our goal is to provide quality products and services to help your business grow.