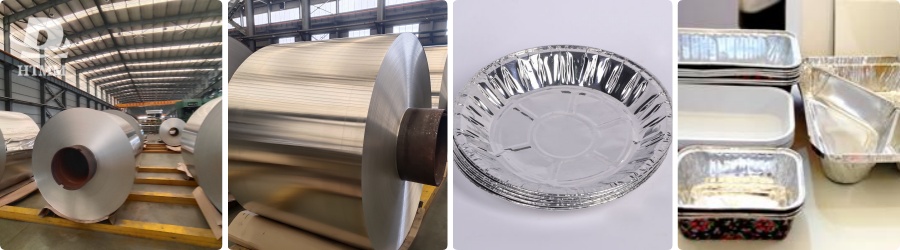

The lubricated food container foil provides a smooth and easy experience for container manufacturers unlike traditional aluminium foil which could be really tricky to work with. The lubricant coating used on the foil gives it lubrication such that it passes through high-speed machines without tearing or damage occurring during any of the shaping or forming process.

These digital twins allow for increased mobility and improve production rates, while maintaining a consistent high-grade finish to the final containers produced. The jumbo roll lubricated food container foil will help manufacturers in achieving complex shapes and sophisticated designs without any worry about faults.

Ease of use is only one of the many benefits of this revolutionary foil. The aluminium core makes them highly puncture- and tear-resistant, and prevents deformation. That’s a big change, and it doesn’t come with a reduction in quality— this solid construction means improved product protection and shelf life, resulting in more value for the consumer.

Today, sustainability plays an important role while manufacturing the containers and jumbo roll lubricated food container foil does this very well. Aluminium is extremely recyclable and the lubricant does not affect its recyclability. Its innovative nature and growing demand for environmentally responsible packaging solutions, makes this product all the more appealing.

In addition to the aforementioned practical benefits, the jumbo roll lubricated food container foil is also one of the most versatile types of consumables available. Its versatility makes it possible to create many different types of containers, from simple trays to more complex shapes, and allows manufacturers to customize their product offerings based on the unique demands of their customers.

The jumbo roll aluminium lubricated foil is a prime example of this creative approach within the dynamic container industry. Unmatched level of efficiency, world-class quality, and environmental sustainability are a trifecta that no other product can put on the table, and therefore, this phenomenal product has remained the top-of-the-line solution for container manufacturers passionate about the upcoming age.

Proper lubrication of aluminum foil is a key factor that can greatly influence the performance and efficiency of high-quality food container placement equipment, so ensuring it is prepared in this way in the above will save countless trouble. Aluminum foil grades used for food-grade containers, aluminum foil 8011 H24 and aluminum foil alloy 3003 H24, need special lubrication methods so that the shaping and forming phase can proceed smoothly and with little effort. A very thin layer of lubricant is evenly spread over the entire surface of the aluminum foil. This serves to reduce the risk of tearing and creasing and increase its flexibility.

The lubrication process enables complex shapes of containers to be manufactured at higher production rates, without jeopardising the foil’s important barrier properties, all while meeting stringent food safety standards. The specific nature and quantity of lubricant utilized can be manipulated by manufacturers to provide excellent food-grade aluminum foil handling performance while maintaining smooth speed and enhancing the durability and overall quality of the foil, instead of increasing its production costs.

The alloy used in aluminum foil plays an important role in the food packaging industry when it comes to acceptable food containers. Two of the most common grades, 8011 H24 and 3003 H24, have their own unique benefits and drawbacks for manufacturers and end-users.

Alloy Composition:

Aluminum foil alloy 8011 H24 and aluminum foil alloy 3003 H24 differ only in the alloy used. They are a group of pure-grade aluminum alloys with a minimum aluminum content of 99.0% making them an excellent selection for any application where corrosion resistance and electrical conductivity is a key concern.

On the other hand, 3003 aluminum foil is a more sulfa alloy with additional elements like manganese and silicon. These attributes consolidate and improve the strength, formability, and corrosion compound in the material and create a beneficial consideration for applications such as food packaging.

Barrier Properties:

Aluminium foil is also largely used for food packaging, as it is one of the most important barrier properties where it will help preserve the freshness, taste and nutrients of the packaged products.

The 8011 H24 customizable aluminum foil container foil offers excellent barrier properties, effectively blocking light, air, and moisture, which helps to protect the food from external factors that could lead to spoilage. For this reason, it can be the best packaging for sensitive or perishable items that need a strong barrier.

It still provides good barrier properties, preventing light, oxygen and moisture from affecting contents in a way in which 8011 is not available (8011 is higher purified than 3003 H24 aluminum foil). 8011 has a slightly lower purity, so it performs a bit worse as a food packaging material.

Formability and Workability:

Aluminum foil must have good formability and workability, which are important for the production of food containers.

3003 H24 aluminum foil is usually much more formable and workable than 8011 H24. The extra alloying elements in 3003 also improve its malleability, resulting in more complex container designs and easier insertion into high-speed packaging lines.

On the other hand, the 8011 H24 customizable aluminum foil container rolls that is purely-graded may not provide the same formability, which may make the container manufacturing process slightly more difficult and necessitate greater care and experience compared to using the other aluminum foil.

Cost Considerations:

Cost difference between 8011 H24 and 3003 H24 aluminum foil for food container Because 8011 H24 aluminum foil and 3003 H24 aluminum foil use different aluminum alloy composition and different production processes, it will have cost difference.

The price of the pure-grade 8011 H24 foil is relatively high because producing high-purity aluminum is generally more energy-intensive and often involves specialized equipment, equipment which has a higher cost. In contrast, 3003 H24 foil, possessing marginally lower purity, is typically more suitable for large-scale food packaging use from an economic perspective.

In conclusion, the decision to use 8011 H24 or 3003 H24 aluminum foil for food containers is a matter of application requirements and a balance of barrier properties, formability, and cost considerations. These are factors that food manufacturers need to consider when selecting the right grade of aluminum foil for their packaging needs.

Common shapes of aluminum foil containers