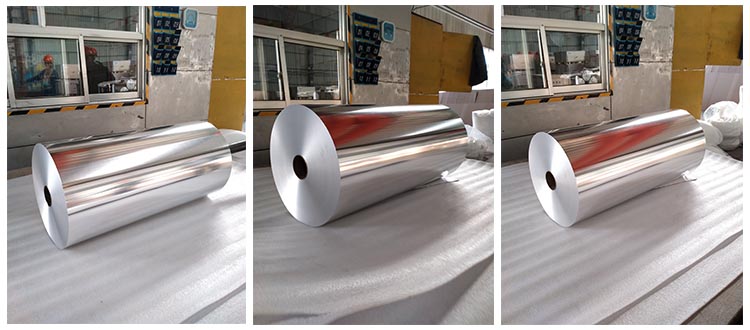

Jumbo Roll Food Packing Aluminium Foil For Lamination 8011

Jumbo Roll Food Packing Aluminium Foil For Lamination 8011

1. In the lamination of FPC flexible circuit boards, silicon aluminum foil determines the quality of lamination, and lamination is also the most important process in FPC board factories. Therefore, pay special attention when purchasing FPC laminated silicon-aluminum foil: *Silicone and aluminum plate should be resistant to high temperature and not easy to deform *flatness should be good *no oil leakage *long service life

2. The test method of silicon aluminum foil is as follows: Appearance inspection: The surface is smooth and clean, without cracks, cracks, particles, bubbles, pinholes and foreign impurities. Thickness: Micrometer measurement, take five points to measure, read the data and record. Size: Measure with a ruler or tape measure, take two equal sides to measure, read the data and record. Temperature resistance: The silicon aluminum foil is heated continuously for temperature resistance test (temperature: 185°C; pre-pressing: 10S; molding time: 120S; pressure 100kg/cm2 for continuous operation for 5 ~7 days), no brittleness is allowed. Silicone oil precipitation: the silicon-aluminum foil is continuously heated for temperature resistance test (temperature: 185℃; preload: 10S; molding time: 120S; pressure 100kg/cm2 for continuous operation for 5 -7 days).

6.5 Micron Alloy 1235 Roll Aluminium Foil For Cigarette Packaging Aluminum foil is still quite a waste of resources. Many cigarette factories have switched to simple aluminum foil