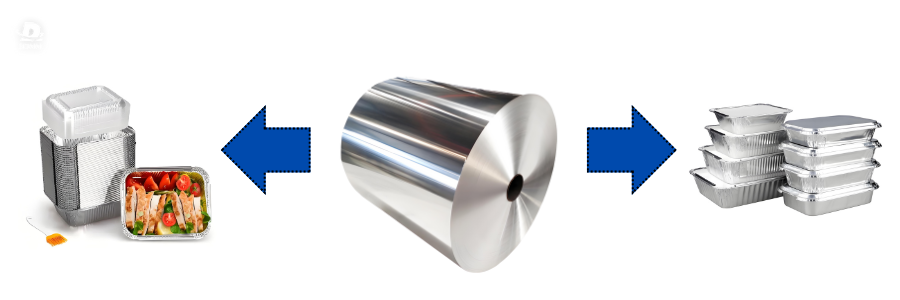

How 3003-H24 Alloy Makes up the Leading Aluminum Food Packaging Production Alloys

3003 Aluminum Foil is a manganese alloy system (1.0-1.5 % Mn) with an order of magnitude higher yielding strength than pure aluminum alloys 1060 or 1100. The H24 temper indicates that the foil has been strain hardened with partial anodization, so users receive a fine balance of properties:

Structural Integrity: It has a yield of 17 ksi and tensile strength of 20 - 26 ksi, so while stacking is typical in shipping, freezing, and display, food containers are not damaged in a state of deformation.

Thermal Properties: It has structural integrity in temperatures from -25°C to 250°C basin temps, making it ideal for a full range of product applications that would be used in the oven to the table.

Barrier Properties: It is >100% barrier to light, oxygen, and moisture. The foil effectively prevents exposure to transpiration in packaged foods, with less than 30% loss of shelf life.

The 50 mic (0.05mm) thickness, unlike thinner foils, provides puncture resistance for sharp or heavy foods while facilitating deep-drawn product designs, such as trays and clamshells.

The Science of Lubrication: Controlling Friction for Perfecting the Forming Process.

Lubricated Aluminum Foil is a specific surface treatment to create a lubricated surface that eliminates the friction generated when you are stamping at high speeds. For container foil, this process is critical, because the lubricant:

Mold Release: (generally food-grade oil or synthetic esters) inhibits the foil from adhering to the stamping dies and reduces separation and tearing during smaller production runs with high speed process forming.

Surface Characteristics: Provides a scratch-free, smooth surface finish that is imperative for consumer grade containers.

Tool Life: Wear to stamping dies and tooling will be reduced with the use of lubrication , maintenance costs are in the ~15% range.

Without lubrication, the 3003 Aluminum Foil level of ductility was possible to seize, or demonstrate micro-fracturing in the most complicated molds and draws.

Ethiopian Market Applications: 50 Mic Foil Utilization

In Ethiopia, Lubricated Aluminum Foil 3003 H24 50 Mic is driving growth under two core container foil segments:

Takeaway & Catering Events: Disposable tray manufacturing for large-scale events and urban food delivery where heat retention is needed for stews, or wat and tibs.

Frozen Meals: Microwave-able frozen injera and vegetable containers use lubricated foil for the retained heat for even reheating.

The Ethiopian container foil market is focused on thicknesses greater than 40 microns for better durability while transporting across challenging topographies, which are meant to mimic the resistance of the 50 mic standard.

Sustainability and Compliance: Beyond Performance

3003 Aluminum Foil promotes circular economy objectives:

Recyclability: It can be infinitely recycled and retains a material property of 3003 Aluminum Foil and uses less in landfall sites.

Food Safety: We comply with FDA and ISO guidelines for direct contact with food because none of our products have BPA’s or phthalates on them.

Carbon Footprint: Ethiopian importers will keep purchasing rolls with over 70% recycled content to satisfy eco certification requirements.

Final thought: The increased use of 3003 Aluminum Foil, and in particular, Lubricated Aluminum Foil 3003 H24 50 mic, demonstrates the ever-growing importance of high-performance, sustainable container foil in the world. In markets like Ethiopia this alloy provides not just strength and performance of manufacture but also the environmental imperative, at the same time. As packaging follows the current evolutions, we believe the 3003 Aluminum Foil will remain at the forefront of combining innovation and performance.