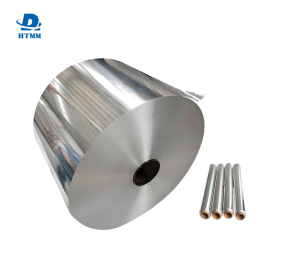

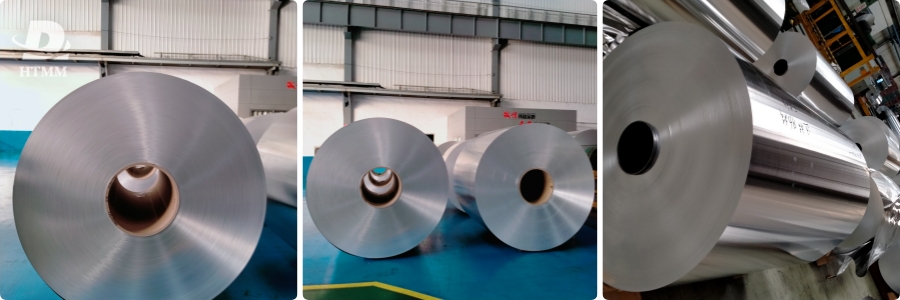

7-Micron & 9-Micron 8079 Aluminum Foil Jumbo Rolls

Now, let us review the differences between 8079 aluminum foil jumbo rolls of 7 and 9 microns:

Thickness and Basis Weight

The clearest difference between the two foils is their thickness. The 7 micron foil is much thinner than the 9 micron equivalent, with a basis weight (the weight of foil per unit area) of around 19 g/m² versus 24 g/m² for the 9 micron foil.

Such differences in thickness and basis weight have varying implications for foil performance and the appropriateness of its application.

Strength and Durability

9-micron 8079 aluminum foil jumbo roll is more durable than 7 micron aluminum foil. This thickness increase gives it a higher tear/ puncture resistance which is ideal where heavy loads, sharp edges or other aggressive conditions to the foil may occur.

Owing to the additional durability, this type of foil is especially helpful in industrial packaging applications, where foil could serve to wrap or line heavy machinery, protect sensitive components from the environment, or serve as a core for tamper-evidence seals.

While the 7 micron aluminum foil also has reasonably impressive strength given its reduced thickness, it might be more prone to accidental damage or perforation. This may be an important factor for applications where the foil should remain undamaged during handling, transportation, or storage.

Barrier Properties

7 micron and 9 micron 8079 aluminum foil jumbo roll excellent barrier property which protect the contents from the light, oxygen and moisture. Nevertheless, the thicker 9-micron foil could form a slightly more robust barrier for sensitive or perishable goods.

The improvement to the barrier can be critical in such fields as pharmaceuticals, where the physical security of the packaging is crucial for the safety and efficacy of the sealed medication. This can also be helpful in the food and beverage segment as the foil can be utilized to preserve the freshness and quality of the packaged products.

The basic ideas of formability and convertibility

These thickness variations can also affect the formability of the foil itself, which additionally affects its convertibility, or its ability to be easily formed, shaped, or converted into various packaging components.

The 7-micron foil has a thinner structure which in general provides more flexibility and conformability. It can thus facilitate its use to produce ornate or custom-shaped packaging or specialty lots wherein the foil may need to be molded around uneven surfaces or depressions.

In contrast, the 9 micron aluminum foil is arguably less formable than the 7-micron foil, requiring somewhat more time and specialized equipment to achieve the desired shapes or configurations, although it is still very formable. On the other hand, this thickness can also give higher dimensional stability and in applications to get the foil to keep the form it needs to have.

Cost and Sustainability

When comparing 7 micron and 9 micron 8079 aluminum foil jumbo rolls, there is another important aspect to consider, cost and sustainability factor.

In most cases, the price of 7 micron aluminum foil is higher than that of 9 micron aluminum foil because the thinner 7-micron aluminum foil requires stricter production control and technical requirements to meet the qualified standards. This has long been an important consideration for companies and manufacturers who pay attention to budget and material costs.

The use of less material in the 7-micron foil can also reduce the environmental impact. Since aluminum is a highly recyclable material, the production of thinner foils typically translates to reduced energy use and greenhouse gas emissions during manufacturing.

Therefore, companies with different philosophies have different views on 7-micron aluminum foil: companies that value economic benefits will not choose 7-micron aluminum foil first, while companies that value environmental protection and sustainable development prefer this environmentally friendly material.

How to Choose the Right Thickness of Aluminum Foil?

There is no definitive answer when it comes to choosing between the 7 micron vs 9 micron 8079 aluminum foil jumbo rolls. The decision between these two thicknesses will depend on several factors, including the use case, the necessary protection, processing requirements, and overall budget and sustainability considerations.

On the other hand, if you require a stronger, more durable barrier with superior barrier properties for your application, the 9-micron 8079 aluminum foil may better meet your needs. The increased density also offers them expanded protection for delicate or high-value products and greater resilience also to physical damage during handling and shipping, however, they do add some weight.

If flexibility and formability production are key factors driving the purchasing decision, then the 7 micron 8079 aluminum foil could be the better option. Since it has a thinner profile, it also becomes easier to handle while designing custom packaging solutions, and its relatively low use of material amounts to substantial cost-saving.

In conclusion, if you still have difficulty determining which between the 7-micron and 9-micron 8079 aluminum foil jumbo rolls to choose, try to think if the former works for your needs, and if it does not, then check the latter. Having a clarity and knowledge of the differences between the Two products is helpful for making best decisions which align with your business goals and optimize your packaging process in matter of performance per requirement.