8011 aluminum foil is well-regarded for its flexibility and formability, making it a good choice for household foil and a flexible packaging material where ease of handling and dead-fold properties are key.

8079 aluminum foil is known for its superior moisture and gas barrier properties and higher puncture resistance, this is why it's typically chosen for blister packs in the pharmaceutical industry and for sensitive food packaging applications.

1235 aluminum foil is known for its high purity (99.35% aluminum) giving it excellent barrier performance; 1235 has significance in high-end flexible packaging applications that require absolute protection against oxygen and moisture.

3003 aluminum foil, with the help of managed manganese, offers additional strength and is used in heavier-duty, thicker foils, such as in container lids and for industrial usage. Knowing these baseline differences will help packaging professionals to choose the correct material satisfying the performance, cost, and processing criteria for their requirements.

Upon closer inspection of 8011 aluminum foil, its versatility comes through in household and industrial applications. This alloy is well balanced composition and provides excellent elongation properties for converting into Jumbo Rolls of Aluminum Foil for high-speed packaging lines. The tear resistant properties of the 8011 and soft temper will allow for easy processing, as well as strength through as the foil goes through various lamination and printing processes.

Food manufacturers prefer this alloy in packaging for chocolate and dairy products for the non-reactive materials and good barrier properties. The excellent thermal conductivity of the alloy, for either freezing or oven, makes it versatile, and the foil shows tremendous adaptability and flexibility in meeting the demands across temperatures, whether hot or cold.

Compared to some of the specialized and non-specification grades of aluminum foil, 8011 provides an incredible cost performance value, and robustness for substantially protecting many standard packaging needs without the additional costs of specialty alloys. The abundance of familiarity with household foil products is evidence of the balance of performance characteristics for large volume production in meeting everyday consumer needs while achieving economies of scale.

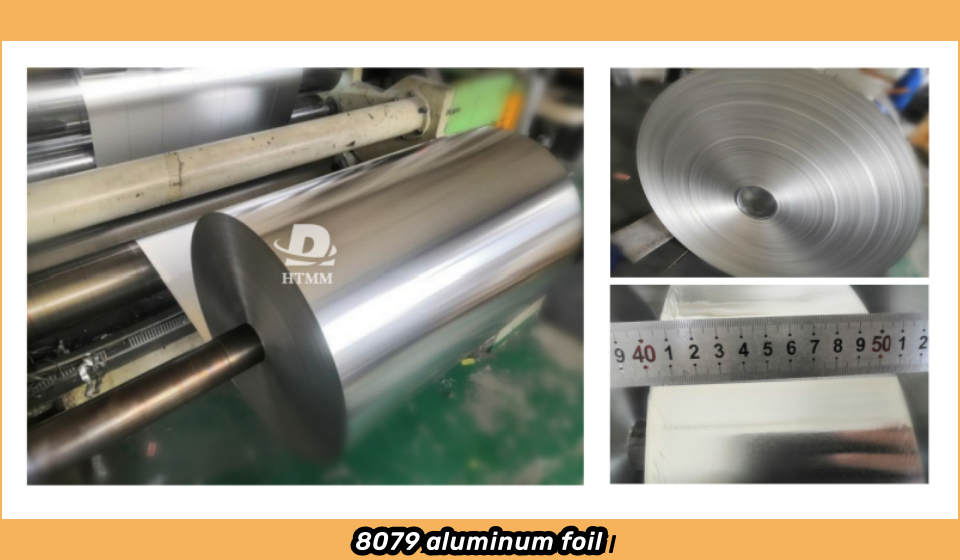

The foil alloy 8079 differs from other aluminum foil alloys in that it has certain specific properties that enable it to deal with more difficult packaging situations. In particular, 8079 foil has higher levels of iron and silicon than does 8011 foil.

These improvements in puncutre resistance and barrier performance are essential benefits in the packaging of pharmaceutical products as well as sensitive food items. Additionally, the 8079 allele's mechanical strength allows deeper blisters to be formed in instance of pharmaceutical packaging while still minimizing the risk of the foil breaking during the molding process.

The superior strength of the 8079 foil creates opportunities for food manufacturers dependent on foil packaging that are producting sharp or irregularly based foods during the filling and handling processes. Both of these improvements in properties and features should be considered when selecting aluminum foils. While some other alloys will experience decreased barrier properties in thinner gauges, 8079 provides consistent barrier properties in multiple laminating processes, reducing waste and the risk of spoilage or product loss.

In fact, the consistent performance characteristics of 8079 established it as the preferred aluminum foil for converters who frequently laminate foil of many different substrates with adhesive systems or multilayered laminate constructions. In summary, the specialized properties of foil alloy 8079 explain the reason for the aluminum foil becoming the major foil of choice for applications where foil failure cannot occur, such as the packaging of medical devices or the packaging of premium food products with an extended shelf life.

Pure performance is what 1235 aluminum foil is all about, and at the same time, it is literally the gold standard for critical barrier performance in flexible packaging. The aluminum alloy is primarily 99.35% aluminum and as a result of this high aluminum content, we are minimizing other elements that can create impurities which can impact barrier performance or create pinholes in thin gauges.

This purity creates the value for 1235 aluminum foil for ultra-high barrier applications such as coffee capsules, retort pouches, and sensitive pharmaceuticals where a small amount of oxygen transmission can damage the integrity of the product. 1235 has excellent surface characteristics and can yield better metallization substrates, leading to barriers incorporating aluminum foil composites even further. In terms of formability, 1235 aluminum foil offers marginally better formability compared to 8011 and 8079, allowing for more intricate designs for package formation with little cracking or stress marks.

All aluminum foils provide very good barrier properties, but when purity is evaluated with consistency, 1235 delivers gains in actual performance in laboratory tests (although we would not guarantee that any of the various polymer and foil laminate combinations exist in reality). Packaging engineers work with the most sensitive products—where product protection is product livability—are keenly aware of the purity and performance of 1235 aluminum foil and continue to communicate the value of the 1235 aluminum foil which continues to perform in the most difficult of applications.

The production format is an important consideration for alloy selection in the use of Jumbo Rolls of Aluminum Foil for production scale packaging. All four alloys 8011, 8079, 1235, and 3003 can be produced in jumbo roll formats, however, their processing characteristics vary.

The 8011 alloy is a better fit for high speed converting lines because of the balanced attributes of the the alloy, which makes it easier to print and lamination processes. Converters value the 8079 for its ability to remain intact during the kind or aggressive unwinding and rewinding processes without excessive web breaks and downtime. Beyond product specific use requirements, the quality of the 1235 as a surface material provides more always the same surface quality in the vacuum metallization process for certain types of products requiring synthetic high-barrier wall.

When specifying jumbo rolls it is important for the converter to evaluate not only the alloy's performance attributes for the end use material, but more importantly how it will react or behave during converting processes such as elongation characteristics, tensile strength and work-harden characteristic. As a foil manufacturer it is our responsibility to help our customers as much as we can by aligning alloy specifications and processing data with each customer or end-use application including the equipment of the converter, to assist all parties in obtaining the best value of the project and supply chain from the mill to the packaged product.

In the end, the choice of aluminum foil alloy comes down to a detailed analysis of mechanical properties, cost-to-benefit analysis, and application performance requirements. While most technical applications will benefit from the use of 8011 aluminum foil as the general workhorse, if the package is an extreme circumstance packaging; glass, steel or aluminum foil and extended laminating permit use 8079 aluminum foil for structure.

1235 aluminum foil option is still without parallel when plastic voids are not permitted and purity must equal equal performance for ultra-high barrier applications, on application where maximum heavy duty and structure are needed we have 3003.

Being a manufacturer of all of these alloys in jumbo rolls of aluminum foil, we support our customers by properly discussing and advising the appropriate product and testing with material samples. Each alloy selection affects packaging performance, packaging efficiency, and eventually, success in the marketplace. We want to encourage packaging professionals to speak to our technical team about determining the best aluminum foil alloy, considering application requirements, processing parameters and performance expectations to arrive at far more optimized material solutions for their packaging operations.