Specification

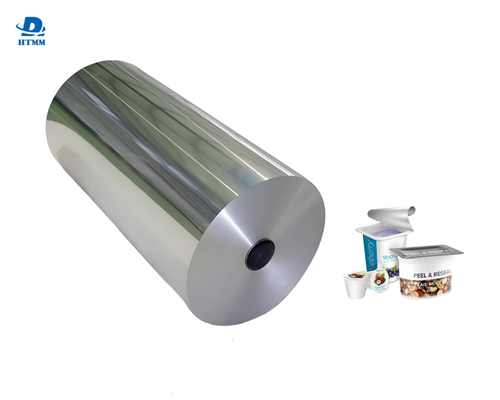

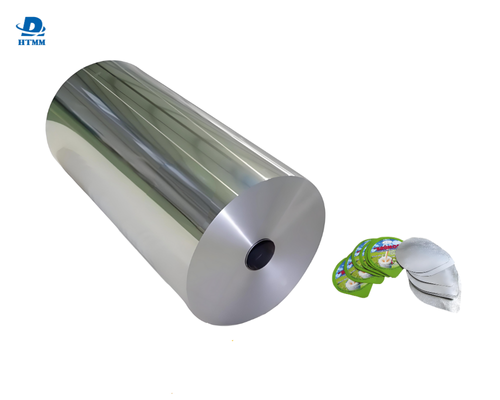

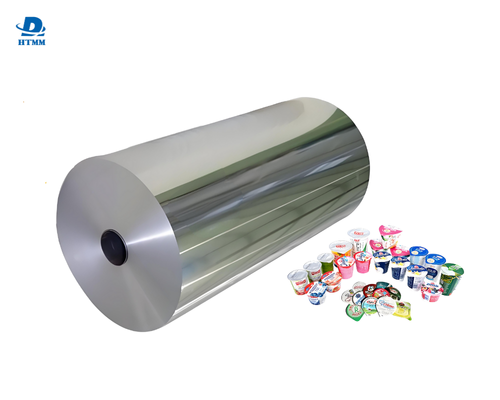

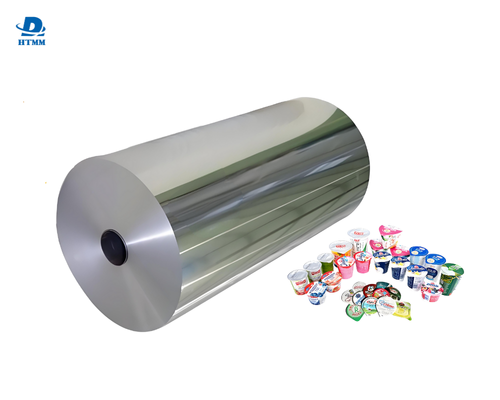

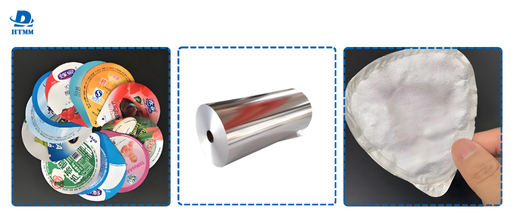

In the yogurt packaging industry, the Aluminum foil jumbo serves as the raw material from which yogurt packs are transformed into an individual, single-serve, foil lid. These lids are usually laminated with a film (either PET or PP film) layer that heat seals to the yoghurt cup. The aluminum foil acts as an effective barrier against moisture, oxygen and light, that is beneficial so yoghurts maintain freshness and quality for as long as possible.

Details include:

| Common Aluminum Foil Specifications for Yogurt Lids |

| Alloy Type |

Temper |

Common Thickness (µm) |

Width Range (mm) |

Surface Type |

Application |

| 8011 |

O |

30 – 45 |

200 – 1500 |

One side bright, one side matte |

Yogurt cup sealing |

| 8079 |

O |

25 – 40 |

200 – 1600 |

Bright or embossed surface |

Yogurt and dairy lids |

| 1235 |

O |

20–40 |

200–1300 |

High purity, soft surface |

Flexible food packaging |

These alloys are deemed appropriate for their great formability, sealing, and hygiene properties. The 8011 aluminum foil is the most frequent material selected for yogurt cups because of its tensile strength and overall barrier performance.

Advantages of Aluminum Foil for Yogurt Cups in the Food Industry

Barrier Performance: Aluminum foil restricts light, oxygen and/or moisture from getting into the package helping to maintain yogurt freshness.

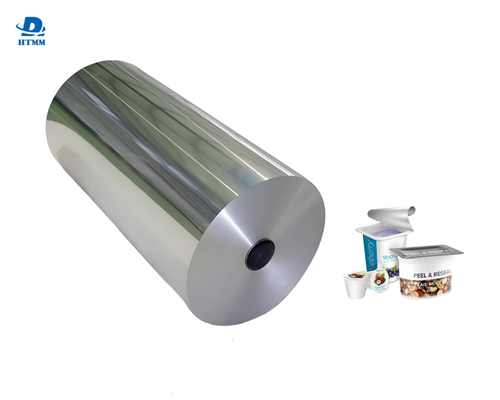

Heat-Seal Ability: Provides a very secure heat-seal with PP or PS cups, protecting against leaks or contamination.

Sanitation Qualities & Non-Toxic: Aluminum foil is considered food safe and is widely used to cover dairy products.

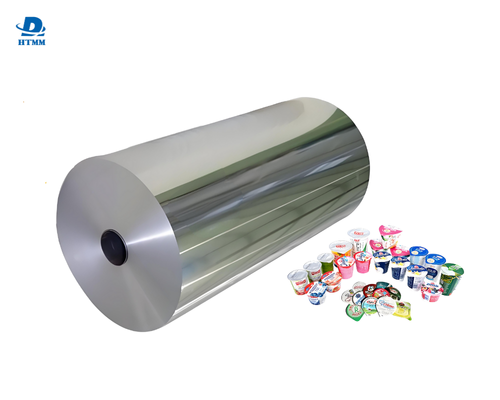

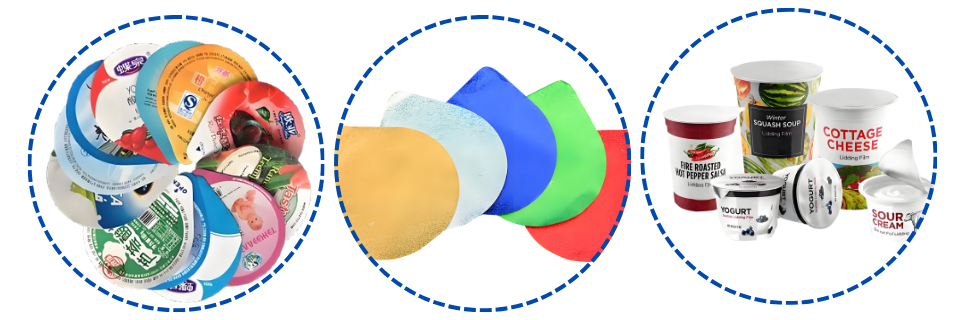

Aesthetic appearance: Aluminum foil can be printed on with multicolor graphical designs and logos to help enhance brand recognition and product visibility on store shelves.

Sustainable Material: Aluminum foil is the most sustainable option, fully recycles better than single use plastic film generating less waste and contamination to the ecosystem, and contributes more toward trending sustainable package growth.

| Advantages of Aluminum Foil for Yogurt Lids Compared to Other Materials |

| Feature |

Aluminum Foil |

Plastic Film |

Paper Lid |

| Light & Moisture Barrier |

Excellent |

Moderate |

Poor |

| Heat Seal Strength |

High |

Medium |

Low |

| Hygiene |

Food-safe |

Varies |

Moderate |

| Printability |

Excellent |

Good |

Average |

| Recyclability |

100% Recyclable |

Limited |

Recyclable |

| Shelf Life Extension |

Strong |

Moderate |

Weak |

Compared to paper and plastic films, aluminum foil yogurt lids provide unique protection while keeping dairy products safe and tasting fresh during shipping and storage.

Global Demand for Lids for YogurtAluminum foil demand from yogurt lids is growing rapidly in the international dairy market, particularly in Asia, Europe, and South America, where consumption has grown with single-serve yogurt cups and food safety awareness.

Asia Pacific: Increasing yogurt consumption has increased the need for aluminum foil packaging materials.

Europe: Strict environmental regulations encourage recyclable aluminum lids over plastic.

South America: The desire for premium dairy packaging and packaging display motivates increasing demand.

The global trend suggests that the aluminum jumbo roll for yogurt lids will remain at the forefront of the international sustainable packing movement.

Questions and Answers About Aluminum Foil Yogurt Lids1. What alloy is best to produce yogurt aluminum foil lids?The most common alloys for yogurt aluminum foil lids are 8011-O, 8079-O, and 1235-O.

8011-O: It provides good strength and barrier properties.

8079-O: This alloy is known for its high elongation properties, or greater flexibility.

1235-O: Preferred for its high purity and ductility.

2. What thickness should yogurt lid aluminum foil be?Common thicknesses can range from 25 to 45 microns (µm) depending on the yogurt container, sealing layer, and mechanical strength.

25-30 µm: Use for light weight applications

35-45 µm: Used for yogurt lids.

3. What surface treatments will aluminum foil yogurt lids have? Aluminum foil will have any surface treatments before lamination or printing.Primer coat for better ink adhesion.

Lacquer coat for heat sealing

Embossing for decorative texture, or easy tearing

Polishing or bright finish for gloss

4. What is the function of the heat-seal layer in yogurt lids? The heat-sealing layer (typically PET, PP, or PS film) is laminated to the aluminum foil to ensure the aluminum foil can seal tightly with the yogurt cup without leaking. Also, it allows the lid to peel easily without the yogurt cup tearing which creates the users preference of convenience and hygiene.

5. In what ways do aluminum foil lids help in food safety and freshness? Aluminum foil has total barrier qualities to light, oxygen, water vapor and odor. It protects against bacterial contamination, oxidation of flavor and loss of flavor - thereby maintaining yogurt freshness longer.

6. What are the standard size widths and cores for jumbo rolls of aluminum foil for yogurt lids? Width: 200 mm - 1600 mm (customizable)

Core ID: 76 mm or 152 mm (paper or aluminum cores)

HTMM can customize the roll gauge based on your slitting machine specifications.

7. Can aluminum foil yogurt lids be printed or embossed?Yes. Aluminum foil has a fantastic printable surface to allow multi-color flexographic, rotogravure or digital printing to be applied. Embossed foil lids can also be made in order to create texture, design style and to differentiate your brand.

8. Can the foil be customized to the cup material (PP, PS, or PET)?Yes. The sealing lacquer or film would be matched to the yogurt cup plastic type to achieve a successful seal. For example:

For PP cups → aluminum + PP film

For PS cups → aluminum + PS lacquer

For PET cups → aluminum + PET film