Specification

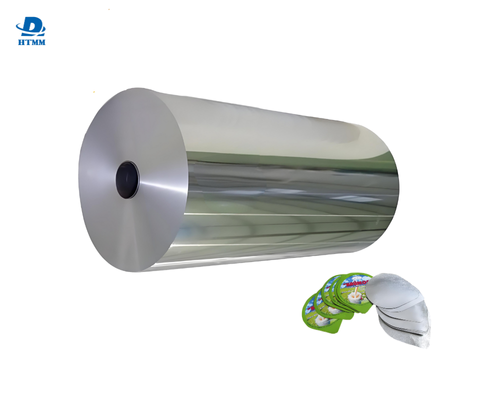

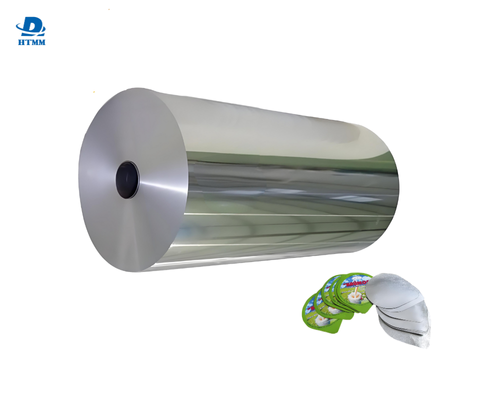

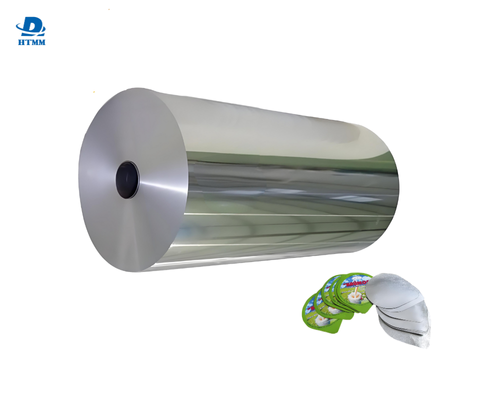

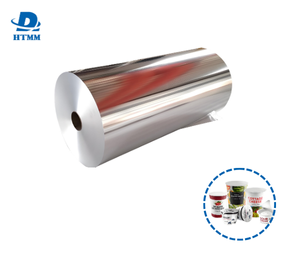

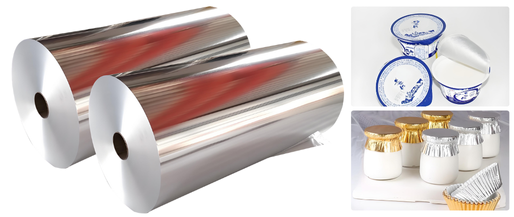

Heat-sealing aluminum foil is intended to create an airtight, safe, and tamperproof closure for a wide range of food and beverage packaging applications. Aluminum foil, with the addition of a heat-seal lacquer or as a laminate, can provide a permanent bind to plastic, paper or glass containers under heat and pressure. This also protects the product from contamination, moisture, and oxidization, which is important for extending the shelf life of a product, ranging from yogurt, coffee, sauces, ready-to-eat meals, and more.

Notably, the hot sealing aluminum foil 8011 1235 series is highly regarded for its mechanical properties, chemical stability, and conformity to international food safety regulations. Both alloys offer superior flexibility, light weight, and recyclability that facilitate sustainable packaging.

Details include:

Type |

Heat Sealing Aluminium Foil(Lid Foil) |

| Application |

To be used for food contact lid, by heat seal with PET |

| Grade: |

Food |

| Alloy |

8011 1235 8079 |

| Temper |

O |

| Thickness |

0.025MM-0.05MM |

| Width |

150MM-1000MM |

| Surface |

One side bright, One side matt OR Both sides bright |

| Packaging |

Free Fumigated wooden box |

Benefits of Heating-Sealing Aluminum Foil Include: Food-Grade Compliant Product: All material meets international food contact standards (FDA, EU).

Excellent Barrier Properties: Good barrier properties of moisture, light, and oxygen to maintain flavor and quality.

High Sealing Strength: Consistent sealing strength over varying temperatures.

Excellent Printability: Smooth surface for colorful designs and logos.

Recyclable and Environmentally Friendly: 100% recyclable and eco-friendly packaging.

Customization of Production: Thickness, width, and type of lacquer can all be modified.

Strong Support for Exporting: Safe export packaging, timely delivery, and technical support offered by HTMM.

FQAs: 1. What alloys are used most frequently for heat-sealing aluminum foil? The most used alloys are: 8011-O and 1235-O have sealing ability, barrier protection, and flexibility.

2.What thickness will heat-sealing aluminum foil come in for regular thickness? Common thickness ranges from 15 to 45 microns depending on the exact application – thinner for packaging applications, thicker for container seals.

3. Are aluminum foils made to order on the customers packaging line? Yes, HTMM customizes all widths, thicknesses, core diameters, and coatings to fit various sealing machines.

4. Can the aluminum foil touch food? Yes, HTMM makes food grade aluminum foil that has been tested for cleanliness and migration for first food contact.

5. How is heat seal performance accomplished? Heat seal performance is accomplished using a heat seal lacquer that is coated or laminated to a supporting line of PP, PS, or PET and activated in a controlled environment with heat.

6. What surface finishes are available? One side bright / one side dull, embossed, or coated - the finish depends on what to be used for your final product and the requirements for sealing.

7. How should the aluminum foil rolls be stored, prior to production? Aluminum foil rolls should be stored in a dry, well ventilated environment, with as constant temperature (15C to 35C) as possible, to prevent oxidation or moisture absorption.

8. What are the dominant application spaces for 8011 and 1235 foils? 8011 Foil - yogurt lids, pharmaceutical applications, beverage seals.

1235 foil: Snack bags, layers of lamination, candy and chocolate wrappers.

9. What will the minimum order quantity be?Typically, our MOQ is 3 tons per size, but we can accommodate trial orders for new clients.

10. What test methods does HTMM use to verify foil quality?HTMM performs pinhole tests, tensile strength tests, seal tests, and surface review on every production run.