The Growing Demand for Quality Container Foil

The Saudi Arabian market has seen an unprecedented growth in the demand for aluminum container foil products. With the rise of food delivery services and takeaway culture, manufacturers need to make informed decisions about their container foil alloy selection.

Understanding Container Foil Basics

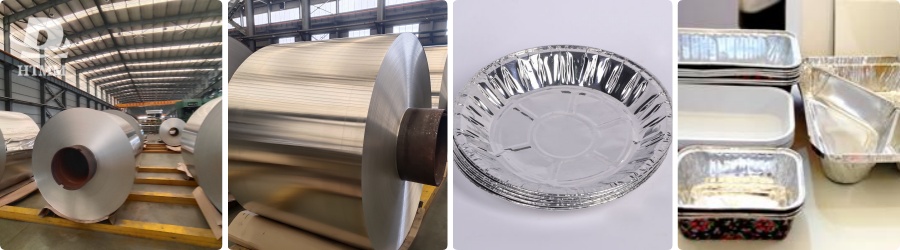

Container foil alloy composition plays a vital role in determining the strength and durability of the final product. HTMM, a leading Henan aluminum foil supplier, emphasizes that the right alloy selection is as crucial as choosing between container foil 50 micron and 60 micron thicknesses.

The 50 Micron Option: Advantages and Applications

Container foil 50 micron thickness is particularly popular in the Saudi market for several reasons. This thickness offers a good balance between strength and cost-effectiveness, making it suitable for many standard food packaging applications.

When to Choose 50 Micron Thickness

Many Saudi manufacturers opt for container foil 50 micron when producing containers for lighter food items. The container foil alloy used in this thickness provides adequate strength for most everyday applications while maintaining cost efficiency.

The 60 Micron Alternative: Enhanced Durability

Container foil 60 micron thickness offers enhanced durability and is often recommended by HTMM for specific applications. This thickness provides extra protection and stability for more demanding uses.

Applications of 60 Micron Container Foil

In the Saudi market, container foil 60 micron is preferred for premium packaging solutions and heavy-duty applications. The thicker gauge ensures better handling during transportation and storage.

Cost Considerations in Container Foil Selection

When comparing container foil options, manufacturers must consider both immediate and long-term costs. While 50 micron options might seem more economical initially, certain applications might benefit from the durability of 60 micron solutions.

Market Trends and Consumer Preferences

.png)

Saudi consumers increasingly demand high-quality packaging solutions. This has led to a growing appreciation for properly selected container foil products that maintain food freshness and presentation.

The Role of Container Foil Alloy Selection

The container foil alloy choice significantly impacts the performance of both 50 and 60 micron products. HTMM's expertise in alloy formulation ensures optimal performance across different thicknesses.

Temperature Resistance and Stability

Both container foil 50 micron and container foil 60 micron options must withstand various temperature conditions common in Saudi Arabia's climate. The right thickness choice depends largely on specific usage requirements.

Production Efficiency Considerations

Manufacturers must consider how different container foil thicknesses affect their production processes. HTMM provides technical support to optimize production efficiency regardless of the chosen thickness.

Environmental Impact and Sustainability

The thickness of container foil can affect recycling efficiency. Both 50 and 60 micron options from HTMM are designed with environmental considerations in mind.

Quality Control and Standards

Maintaining consistent quality in container foil production is essential. HTMM's quality control processes ensure reliability in both 50 and 60 micron products.

Storage and Handling Requirements

Different container foil thicknesses may require specific storage and handling procedures. Understanding these requirements helps maintain product quality throughout the supply chain.

Market-Specific Considerations

Saudi Arabia's unique climate and market conditions influence the choice between container foil 50 micron and 60 micron options. HTMM's expertise helps manufacturers make informed decisions based on local requirements.

Cost-Benefit Analysis

A thorough analysis of both options helps manufacturers determine the most suitable container foil thickness for their specific needs. This includes considering both immediate costs and long-term benefits.

Future Trends in Container Foil Technology

The container foil industry continues to evolve, with HTMM leading innovation in both 50 and 60 micron products. Understanding future trends helps manufacturers make forward-thinking decisions.

Making the Final Decision

When choosing between container foil 50 micron and container foil 60 micron, manufacturers should consider all factors discussed above. HTMM's technical support team can assist in making the optimal choice.

The selection between container foil 50 micron and 60 micron options requires careful consideration of multiple factors. Working with experienced suppliers like HTMM ensures access to quality products and expert guidance in making this crucial decision.