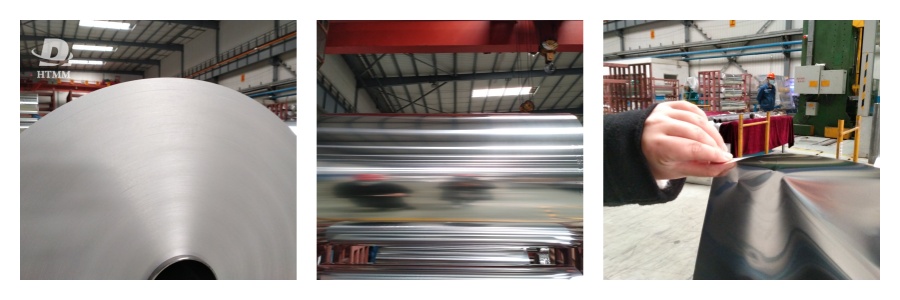

Structure is very important for food safety. High quality foils use primary aluminum between 99.5-99.9% pure aluminum. It meets Food and Drug Administration standards for direct food contact. Cheaper foils may contain recycled materials that carry a higher risk of contamination. Production methods are also important - foils produced through a continuous rolling process at consistent speed and temperature as opposed to a batch process will have a more uniform thickness and a lower risk of contamination. Appropriate lubricants are also used during rolling. Physical testing can also determine quality - the higher the percentage of expansion during flexing/bending before cracking, the more durable the foil.

Ensuring proper quality control throughout production preserves the performance of the aluminum foil in the intended application. Major brands perform frequent tests to verify that thickness, degree of purity, barrier properties and other standards are consistently met. Rigorous supplier qualifications and third-party audits inspect conditions. Traceability systems such as barcode labeling allow product details to be identified if ever required. Together, these measures provide confidence that aluminum foil reaching customers and customers worldwide delivers the safety, versatility and sustainability qualities expected of high-quality aluminum.

Many people take household aluminum foil for granted as a tool for storing and preparing food. However, foil's ability to preserve freshness is due to its unique material qualities as the world's second most extensively used metal after steel. This in-depth tutorial delves into the scientific concepts that enable foil to seal in tastes, maintain nutrients, and increase the shelf life of leftovers, baked goods, and more.

Household aluminum foil's barrier qualities make it a useful storing material.Household aluminum foil's ability to keep food fresh is due to its better barrier properties:

There are 5 Key Advantages of Factory-Direct Household Aluminum Foil

1.Price Advantage, Extremely High Cost-Effectiveness

• By bypassing intermediaries and reducing distribution markups, the final selling price is more competitive.

• For the same budget, you can get a thicker, wider, or longer product, significantly improving practicality and cost-effectiveness.

2.Stable Quality, Strict Quality Control

• Direct connection to the production line ensures consistent product quality standards and high batch stability.

• Customization options are available for specific alloys (e.g., 8011), thicknesses (e.g., 12µm, 18µm), and surface treatments to meet diverse usage needs.

3.Flexible Specifications, Customization Support

• Width, length, core size, and even printed markings can be customized to meet specific requirements.

• Suitable for special applications (e.g., outdoor camping, commercial catering) or as corporate gifts.

4.Stable Supply, Ample Inventory

• Direct access to factory inventory ensures guaranteed supply for bulk purchases, avoiding the risk of market shortages.

• Safety stock and dedicated logistics arrangements can be negotiated for large clients.

5.Direct Technical Support and After-Sales Service

• Access to product usage advice and technical parameter specifications directly from the factory.

• Shorter communication channels and more efficient problem-solving in case of quality disputes.

Sustainability is another focus, from utilizing renewable energy to minimizing use of resources. Aluminum foil is infinitely recyclable— foil scraps and post-consumer foil are harvested and reconstituted back into usable coil at our facilities. Our efforts have resulted in Platinum certification from independent verifiers.

With several facilities worldwide, including locations strategically positioned near key markets, HTMM offers reliable global supply of customized foil solutions. Our sales and technical experts are on hand to advise clients across all stages—from initial concept and trials to large-scale production and shipping.

An integrated ERP system also streamlines ordering, quoting, inventory, and fulfillment for a smooth customer experience. Meanwhile multi-lingual staff can liaise effectively with global clients in their preferred language.

For those seeking private label partnerships, HTMM operates toll manufacturing programs to produce custom foil solutions under other brands. Comprehensive services include product development, branding, packaging design, certifications, and global distribution to major markets.

Quality, variety and value - this is what you can expect from working with us as one of the best aluminum foil manufacturers. Whether you need basic wraps for home cooking, heavy-duty performance for production baking or ultra-robust foil for punishing industrial uses, we have an option that will exceed your needs. Benefit from our experience supplying international brands and a local factory to source domestic aluminum foil rolls tailored for Russian applications and standards. Contact us today to discuss your specific requirements and how we can assist your foil packaging needs.