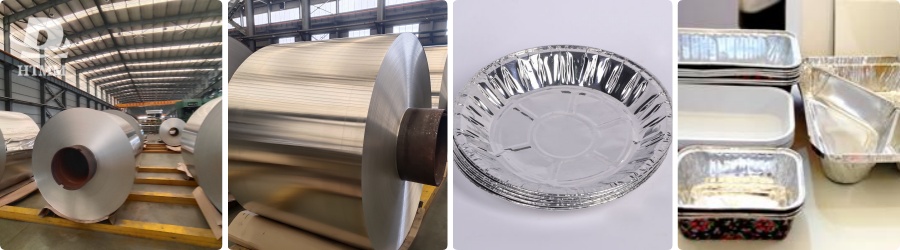

What is Container Foil?: The performance building blocks

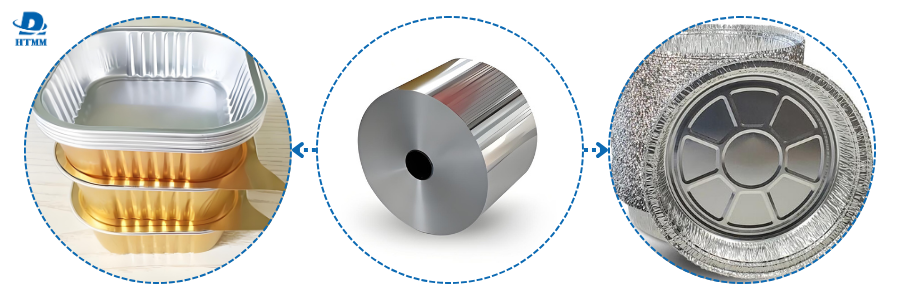

Container foil is a special grade of aluminum foil specifically manufactured for forming-in trays, pots, dishes, and lids. It most distinguishing property is that it has particular mechanical properties that are not present in thinner household foils - the most critical of which include strength, formability and rigidity. These characterstics help to maintain the integrity of the container during the forming, filling, sealing, transportation and into the consumer hands.

Aluminum Food Container Foil Key Properties & Benefits

Excellent Barrier Qualities: This is the number one benefit! Aluminum foil has an absolute barrier to moisture, oxygen, gases, light (to include UV) and micro-organisms. This barrier prevents food from drying out, absorbing contaminants, oxidation (leading to rancid), or spoiling from light. It keeps freshness, flavor, and aroma a whole lot longer than other possibilities!

Excellent Conductivity: Food aluminium container foil has fantastic thermal conductivity because it offers optimal heating and freezing. It heats evenly and fast in conventional ovens so that food is heated thoroughly or cooked well. On the other hand, food aluminium container foil also freezes quickly which keeps food out of the "danger zone" and preserves the food's texture and quality. This ability for aluminium food container foil to accommodate heating and freezing is a great benefit for all ready meals.

Lightweight and Spatial efficiency: Foil containers by design are light weight reducing transport costs and environmental footprint when compared heavier materials such as glass or clay. Foil containers are nested or stacked reducing space when storing items which also conserves space.

Sustainability and Recyclability: Aluminium is infinitely recyclable and does not lose any quality in the process. Container foil products can be recyclable when there is collection infrastructure in place. Using recycled aluminium to manufacture food container foil products is a great advantage since it uses less energy than manufacturing the primary metal.

Safety and Hygiene: Aluminium foil is biologically sterile and supplied as a non-porous substrate, which eliminates the growth of bacteria and the migration of materials into the food, and conforms to the rigorous new food and safety criteria.

When is 35 Micron (H22/H24) foil Appropriate?

This film construction - 35 microns, 8011/3003, H22/H24 - is the workhorse for semi-rigid container foil products. The semi-rigid containers provide more structural support than a thin, flexible foil pouches but not as much as a heavy-gauge tray. Typical applications include:

Ready-meal trays: This thickness represents the standard for a broad range of frozen and chilled ready meals. The thickness provides sufficient rigidity for stacking of the trays, and heat from the oven (even with fan assisted), and offers a good barrier for shelf life.

Take away containers: Used for individual portions of curries, rice dishes, pasta etc. The thickness means they hold their shape while hot or cold during transport.

Pie dishes and quiche pans: This thickness offers adequate support for filled pastry dishes while cooking or serving.

Deli containers: Used for salads, cold meats, dips and sides.

Pet food trays: Provides robust packaging for wet and semi-moist pet foods.

Shallower baking trays and roasting dishes: More suited for items like roasted vegetables, small cuts of meat, and baked items where depth is not extreme.

In stock at this time in these alloys and tempers is the 35 Micron Aluminum Foil In Roll Jumbo, which offers the optimum balance: deep-drawability for forming, enough post-formed stiffness for functionality, consistent and reliable barrier properties, and price competitiveness for high volume production.

Container Foil vs. Paper Containers: It’s clear from the beginning.

While each material presently serves the food packaging market, aluminum foil containers create distinct advantages over paper or paper-based products, particularly in demanding circumstances:

Barrier Performance:

Foil: Completes an almost total barrier to moisture, oxygen, light, and aromas. Critical for shelf life of moisture-sensitive foods (prevents sogginess or drying out) or fat-rich foods, (prevents grease migration).

Paper: Is naturally permeable. Needs some PE, PLA, or some other plastic coatings or laminations to provide any barrier at all. Even when coated, barrier mattresses will be less than that which foil offers against moisture, oxygen, or aromas. Unless coated heavily, paper will readily allow for grease to penetrate into the food.

Heat Performance:

Foil: Can invoke directly from freezer to oven (conventional, convection, often even grill/broiler) without risk of melting, warping significantly (that is, within spec), or leaching. And, foil is even better when it comes to heat distribution.

Ovenable paper. Plastic-coated paper containers often have limited temperature tolerances (typically <200°C) and will melt, deform, or develop fumes if overheated. Uncoated paper is not food safe for use in the oven with wet foods. Susceptible to burning.

Grease resistant:

Foil: Inherently 100% greaseproof and oil resistant. No leakage or staining.

Paper: Needs to be plastic or fluorochemical coated to resist grease. This adds complexity and issues relating to the environment. Performance can vary and change.

Rigidity and moisture resistance:

Foil (Semi-Rigid): Retains shape when wet or containing liquids. Resists drooping. H22/H24 35 micron gives excellent integrity usability.

Paper: Loses a fair degree of rigidity when wet or exposed to moisture or humidity, and can become soggy, leak or collapse, especially with liquidy foods, unless heavily coated/treated.

Sustainability (End-of-life):

Foil: infinitily recyclable when collected separately from food waste in the correct streams. The efficiency of the recycling process depends heavily on local infrastructure.

Paper: Biodegradable/compostable if not coated or coated with certified compostable alternatives (e.g. PLA). Plastic-coated paper tends to not get recycled and go to landfill due to the complexity (requires separation). Compostable papers will be compostable in an industrial facility.

.png)

When looking at food aluminum foil containers and paper versions of comparable items, it really does indicate there are marked advantages in key areas of barrier protection, heat resistance, grease resistance and the structural integrity of the package when subject to load and moisture, the latter for applications where performance is critical. The fact that there is 35 Micron Aluminum Foil In Roll Jumbo In Stock is comforting and enables manufacturers to ensure they have the material available to produce the quality, functional food containers demanded in today's world. When considering the original specification for any type of food packaging (e.g. container foil), it has to be high quality.