What is the Difference Between the Alloys 8011 and 3003?

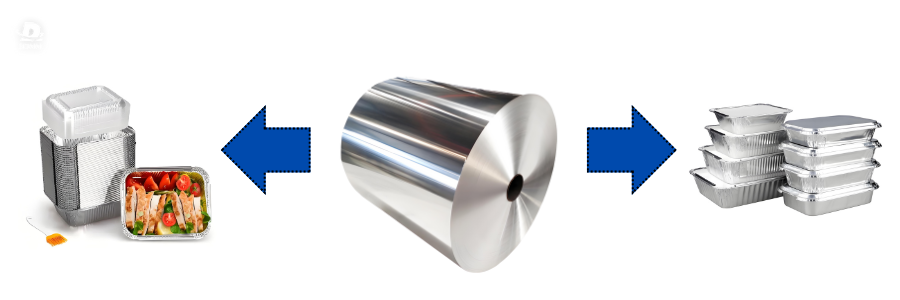

Aluminum foil containers can be made from a variety of alloys, however, the most common two alloys remain 8011 and 3003. Each alloy has its own unique attributes that lend themselves to different uses.

Aluminum Foil Container 8011 is suited for the home and light food packaging industry, for example it has a higher percentage of iron and silicon content which provides a good balance of strength, barrier characteristics and flexibility required for disposable containers, takeaway boxes and wrapping applications. The excellent formability of 8011 allows them to be easily pressed into shapes while incorporating sharp edges without cracking, which is necessary for manufacturers producing in volume.

Aluminium Foil Container 3003 is a typical Al-Mn series foil, but with higher mechanical strength and corrosion resistance. Generally, when processed into foil it is known as 2025 Alloy 3003 Aluminium Foil, which enhances the value of rigidity and strength compared to 8011 foil container. 3003 foil can be used for industrial food packaging, airline catering trays which must hold a lot of weight, and baked containers which have more extensive and demanding cooking applications which would break down 8011 foil.

The Dubai Market and Alloy Usage

Both 8011 and 3003 Aluminium are significant in Dubai's food packaging. Aluminium Foil Container 8011 3003 Dubai, as a term, represents the two demands of cost-effective and high-performance packaging.

Aluminium Foil Container 8011 is a more frequently used for people’s day-to-day requirements, like the small disposables trays, takeaway meal boxes, and cartridge rolls for restaurants and catering services. 8011 also, is a good and functional foil for fast-moving customers products since their affordability and great processing makes the items an obvious choice.

Aluminium Foil Container 3003 is an alloy normally chosen for heavy-duty applications such as the food trays used by the airline industry, ovenable containers, and bulk catering packs. The heavier applications require stronger, and sturdier containers capable of holding heavy portions of food without losing structural integrity when heat is added.

The Dubai market demonstrates a balanced demand for both Aluminium Foil Container 8011 and Aluminium Foil Container 3003, depending on the needs of the food service provider.

Key Types of Aluminium Foil Containers in Dubai

Dubai food and beverage businesses cover a massive spectrum; from house consumption, to hospitality or catering production. The types of foil containers we see the most in Dubai include the following:

Takeaway and Delivery Trays: Small to medium-sized trays made up solely of 8011 foil; predominantly utilized by restaurants and fast-food establishments for convenient delivery of prepared food.

Oven Safe or Baking Containers: Larger trays that are typically constructed using 3003 foil; and intended to be extremely tolerant of elevated levels of heat for prolonged time for the purposes of baking, roasting, reheating, etc...

Airline Catering Containers: Containers utilizing Alloy 3003 Aluminium Foil with a nominal mass make up and durable construction for mass catering in the aviation sector.

Frozen and Ready-Meals Packaging: Use of both alloys depending on the need for lightweight storage or heavy-duty resistance.

The consumption of Aluminium Foil Container 8011 and 3003 Dubai shows the increasing reliance on aluminum foil packaging in the region’s fast-paced food business. While Aluminium Foil Container 8011 is a primary choice for economical weight, Aluminium Foil Container 3003 is the consumer choice for heavy-duty and high-performance applications. Aluminium Foil Container 8011 and 3003 serve Dubai’s food industry's needs for affordability, safety, and sustainability, from a domestic home kitchen all the way to large scale catering and airline service. The demand for hygienic, eco-friendly packaging will only add value to the global and UAE domestic reliance on 8011 and 3003 aluminum foil containers.