.jpg) How Many Meters In 1kg Aluminium Foil ?

How Many Meters In 1kg Aluminium Foil ?

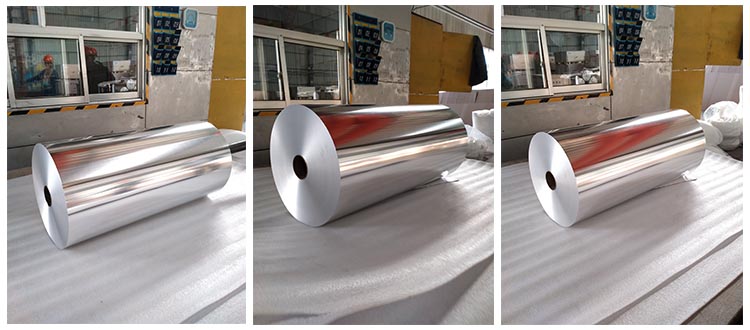

The calculation method of aluminum foil length depends on the length, width, density and thickness of aluminum foil. If there is a composite plastic film, you also need to know the density of the plastic film and the density of the glue. The composite material is collectively referred to as the basis weight (meaning basis weight). Use the simplest The most direct method is to use a microbalance to test the weight per square meter of the aluminum foil and then convert the length of the total weight.

Method two, the density of aluminum foil is known to be 2.71 (using 1mm thick aluminum foil as the standard),

Thickness 0.1mm, aluminum foil net weight 3KG, width 1000mm, calculation method:

Basis weight of 0.1mm aluminum foil: 0.00271*100=0.271

Converted square meters per kilogram: 1 (referring to 1 kilogram)/0.271=3.69003690036 square meters/kg

3 kilograms: 3*3.69003690036=11.070110701 square meters, which is 3 kilograms=11.070110101 meters

Theoretical single roll weight formula: Theoretical single roll weight = (raw aluminum foil thickness × aluminum foil density + dry amount of coating agent) × specification × length (1) aluminum foil density: 2.7 × 103kg/m3 (2) dry weight of coating agent: ordinary Plain foil: 0.006kg/m2 Single-sided printing (including overprinting) foil: 0.007kg/m2 Double-sided printing foil: 0.008kg/m2 High coating amount (6~8g/m2) VC plain foil: 0.010kg/m2 (3 ) Example: Use 0.02mm original aluminum foil raw material to produce single-sided printing foil, slitting a coil with a width of 90mm and a length of 1000 meters. (0.020×10-3×2.7×103+0.007)×0.090×1000=5.49(kg) (4) Change formula length = aluminum foil weight/[(raw aluminum foil thickness × aluminum foil density + coating agent dry amount) × specification] Area = aluminum foil weight / (raw aluminum foil thickness × aluminum foil density + dry amount of coating agent)

Which Side Of Aluminum Foil Should Contact Food ?

The two sides of aluminum foil are different. One side is very shiny, the other side is darker.It is the matte side of the aluminum foil that comes into most contact with food.

The most commonly used aluminum foils are 8011 aluminum foil, 8079 aluminum foil, 3003 aluminum foil, and 1235 aluminum foil.

The surface of 8011 aluminum foil is smooth and clean, uniform in color, flat and free of pinholes and spots. It has excellent light-shielding properties, barrier properties, and moisture resistance. Moreover, the 8011 aluminum foil has high blast resistance, strong puncture and tear resistance, and strong mechanical properties. The most important thing is that 8011 aluminum foil is a non-toxic, tasteless, safe and hygienic raw material. It is a food-grade aluminum foil raw material and can be directly in contact with food. 8011 aluminum foil is widely used as packaging material after compounding, printing and gluing.

8011 aluminum foil is the most common material of aluminum foil. It is usually used in pharmaceutical packaging, lunch box aluminum foil, food flexible packaging, beer sealing foil, adhesive tape foil, barbecue aluminum foil, etc. Its state is 8011-0 (soft).

8079 aluminum foil can be used as a yogurt lid, because 8079 aluminum foil has good moisture resistance, light shading, easy tearability, and safety and hygiene. It is often used for sealing with 8079 aluminum foil, and it is a very popular aluminum foil raw material in the market.

8079 aluminum foil is also widely used in cold-forming medicinal aluminum foil raw materials for various peony packaging enterprises because of its good heat-sealing strength and good sealing performance.

8079 aluminum foil has excellent moisture resistance, barrier properties, sealing properties, electrical conductivity and light-shielding properties, and is suitable for aluminum foil for battery soft packaging.

3003 aluminum foil has good anti-rust properties, easy forming, and corrosion resistance. It is a good raw material for making aluminum foil lunch boxes.

Moreover, 3003 aluminum foil is a commonly used aluminum foil raw material for packaging, and the commonly used states are H14, H16 and H18.

The surface color of 1235 aluminum foil is uniform, clean, and has no color difference on the surface. Moreover, 1235 aluminum foil has good rust resistance, easy formability, and weldability, so it is widely used in cables, adhesive tapes, and battery foils. Cable foil: alloy state: 1235-O, aluminum foil for capacitors: alloy state: 1235-O, battery foil: alloy state: 1235-H18, 1060-H18, 1070-H18, tape foil, 1235-O.

It is your best solution to choose aluminum foil alloy according to your application.If you have any questions, we will serve you.