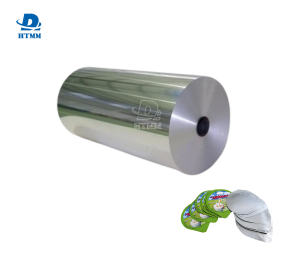

Understanding Alloy: Use Alloys 8011, 1235 and 8079 for Packaging Needs

Flexible packaging aluminum foil provides unique alloys to meet different combinations of packaging needs:

1235 Alloy: Offering 99.35% purity, this foil has excellent flexibility and surface brightness. It is best suited for more complex forming applications and as the most common material used for chocolate wrappers, pharmaceutical blister packs, laminate films (where crease resistance is important).

8079 Alloy: With a high iron content, 8079 foil has superior resistance to puncture and greater elongation; this alloy is the best choice for abrasive products (frozen foods and sharp-edged snacks) and pharmaceutical blister packs that have high mechanical integrity.

8011 Alloy: A balanced "workhorse", combining moderate strength and formability. Common applications include dairy lidding foils (yogurt lids), pouches for oily foods and composite constructions requiring effective barrier performance economically.

Certification Note: Food-safe versions of all three alloys allow for direct food contact and comply with FDA, EU Regulation 10/2011, and ISO.

Thickness: 6-10 Microns in Lamination Systems.

Aluminum foil thickness ultimately determines barrier performance, durability and cost. Each micron thickness tier has different applications for lamination:

6 - 7 Microns: Thin but strong, providing lamination with PET or OPP films to create a high barrier pack for items that need moisture protection (e.g. candy bars, cigarette inner wraps, and pharmaceutical sachets). Resulting in wight saving packs using less material with a high barrier.

8 Microns: As used in all snack (chips, nuts) and coffee laminate. It is laminated with either kraft paper or LDPE or both. When these materials are used, a satisfactory balance of cost and packaging protection is achieved. Blocking UV light and oxygen with some tear resistance during fill.

9 - 10 Microns: Typically used in challenging "hard to pack" products (coffee, spices and oily snacks). Laminated with a heat sealable PE or polyester these thicknesses have more resistance to abrasion and will not have grease migration and prolong shelf life (>30% vs thinner foil).

Benefits of Lamination:

Barrier Synergy: Due to foil's non-permeability plus the polymer's sealability, the amount of O₂/moisture entering the final package is nearly zero.

Printability: High-surface-quality aluminum alloys (e.g., 1235) allows for high color vibrancy of rotogravure branding on outer layers.

Precision in Practice: Choosing the Width of Aluminum Foil

The width of aluminum foil is determined by the type of packaging machinery and the dimensions of the end product:

Narrow Width (200–500 mm): Used for sachets, blister packs or small pouches. Precision slitting (± 1mm tolerance), allows for unbroken integration with high-speed form-fill-seal machines.

Standard Width (1, 000–1, 450 mm): Fits the bulk of packaging lines for snack bags, butter wraps, or medical pouches. Consistency here is important to prevent misalignment during the lamination process.

Large Jumbo Rolls (up to 1, 850 mm): Allow for optimal throughput across large batches. Limits the number of splice points, typically resulting in about ~15% less waste.

Pro Tip: Always check the machinery specifications—using incorrect width can easily lead to jams, wrinkles, and/or seal failures.

Packaging for the Future: Trends and Compliance The transition to thinner but stronger foils (like 7-micron 8079 to replace 10-micron) tells the industry a lot about efficiency improvements. At the same time, recyclable laminates that use foil/paper structures qualify for circular economy models.

Final Thought: Optimize flexible packaging aluminum foil by coalescing three elements – foil alloy to provide product-specific performance, aluminum foil thickness to balance barrier vs weight, and aluminum foil width for to suit the machine. With the new 6-10 micron foils and 8079, brands are enjoying unprecedented shelf life and sustainability; in packaging, we'll always see that precise engineering influences real impacts .