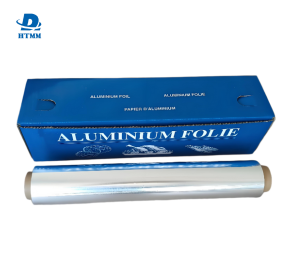

Then we will discuss the outstanding performance advantages of 8079 aluminum foil and why discerning packaging manufacturers in various industries have listed this special packaging material as their preferred packaging material.

Knowing the 8079 Aluminum Foil Alloy

8079 aluminum foil alloy is carefully designed to provide the highest quality packaging materials for the packaging industry. What makes 8079 aluminum foil unique, unlike other general-purpose aluminum foil grades, is its precise combination of alloying elements.

High-purity aluminum is the foundation of 8079 alloy, and its excellent strength, ductility and corrosion resistance are essential characteristics for the packaging industry. , while it also adds other elements - including manganese, silicon and iron - to enhance the overall performance of 8079 aluminum foil jumbo rolls.

The precise composition of 8079 alloy, combined with the specialized manufacturing technology used to create aluminum foil, gives it unique mechanical, chemical and physical properties. This gives it a variety of performance advantages, making it ideal for a variety of demanding applications.

Mechanical Integrity and Durability

The great mechanical strength and durability of performance advantages of 8079 aluminum foil

are among its best qualities. Together with the foil's exact thickness and temper, the strategic alloying elements give the material an extraordinary strength-to---weight ratio that lets it resist notable mechanical stresses and strains without sacrificing its integrity.

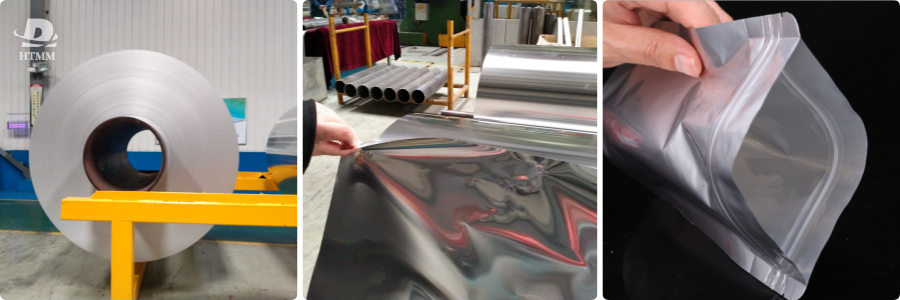

This increased strength also makes performance advantage of 8079 aluminum foil a perfect fit for use cases requiring the foil to hold its shape in tougher environments, including specific types of rigid food containers, heavy-duty baking pans, and as a robust packaging option for delicate electronic products.

Additionally, the reinforced construction and resistance to tear, puncture and cracking makes it dependable for the storage and transportation of products, even those with sharp edges or points.

Barrier protection and maintenance

8079 flexible packaging foil also has excellent moisture resistance and shading performance, which means the compound will not be greatly shaken due to moisture and sunlight. The foil is also naturally resistant to light, oxygen, and moisture, and is thus on excellent minifier of the effects of these on the packaging content.

This protecting barrier is essential especially in cases where the packed article is responsive to degradation as occurs in the food, pharmaceutical and electronic arts. Its excellent properties help preserve the original flavor and quality of the contents, and are further enhanced by keeping the product out of contact with light, moisture.

Additionally, the barrier characteristics of the flexible packaging foil also serve as a barrier against ingress of contaminants, odors and the like into the packaged goods to thereby further increase the overall protection and integrity of the packaging.

Thermal transferring resistance

The thermal performance of 8079 aluminum foil is added to the mechanical properties and other aspects of this product. The great conductor Aluminum is a very efficient heat conductor, which is especially useful in processes where temperature control is important.

In food service applications and some packaging applications, 8079 aluminum foil width is sometimes used in the forming of containers for food packages, particularly if the goods being food package are bulky and difficult to fit in a standard flat bag.

Furthermore, the resistance of the foil to high temperatures, means it can confidently be used for applications that are exposed to hot temperature, like the sterilization of medical products in their packaging or the lining of insulated vessels used for transit of heat sensitive products.

Recyclable and Sustainable

Recyclabilityand sustainability ofpackaging materials have become crucialfactors in many businesses in a world with greater environmental awareness. In this aspect, 8079 aluminum foil is an excellent option because aluminum is one of the most reusable materials on earth.

Without exception, Aluminum is the only material in the consumer/ household marketplace that can be completely recycled over and over again without losing any of the essential properties or quality. This is what makes 8079 “O” aluminum foil so environment-friendly, which can be simply recycled, processed and reused, minimizing the environmental burden of packaging.

As the market of end-use applications for flexible packaging grows, demanding packaging that is more adaptive, high performing and sustainable, 8079 aluminum foil presents as an ever-more appealing and favourable material of choice. From high strength and protective barrier to chemical compatibility and heat transfer take a deeper dive into the aluminum alloy in the domain of foil for countless packaging applications and industrial markets in the future.

.jpg)