This will account for the story of this revolutionary brand, how its various elements influence your packaging strategy. Highly versatile, our Alu foil 8079-O sheets can ensure food freshness and also protect the integrity of pharmaceutical and cosmetic products. Get ready to make a surprise as we show you the many options this small but mighty gift has to offer.

Food grade aluminum foil is applied in very many applications in the food industry and beyond. The major uses of food grade aluminum foil are as follows:

-As part of the food packaging process, it involves covering and sealing various types of food products, for example, sandwiches, snacks, cheese, and baked goods.

-Containers, Trays, and Bowls, Before Serving the Food

Design of bags, pouches, and cases of packaging materials

Using baking papers and lined baking trays will reduce the sticky problem and make it easier to clean up.

Wrap up the ingredients to grill, roast, or even steam in them to maintain moisture and flavor.

Prepare makeshift cooking tools before usage in aluminum foil containers or trays

Food service is the closing and sealing of food containers for caterers, restaurants, and many other institutions that deal with prepared food.

This product provides clean peelable surfaces for food service and presentation.

Pharmaceutical and cosmetic packaging comprises seals and closures for prescription bags, vitamins and nutritional supplements.

Packaging and Sealing Bags for Personal Care and Cosmetics

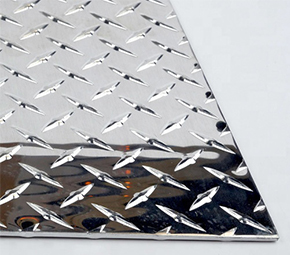

Industrial applications include making barriers for electrical and electronic components.

Isolation and Protection of Various Manufacturing Materials and Equipment.

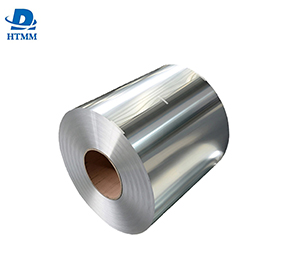

Thin, flexible varieties of food-grade aluminum foil, typically 5-15 microns thick, are best suited for flexible packaging.

An 8011 and 8079 grade for food-grade aluminum foil standards suitable for flexible packaging are these that have previously been molten to attain 5-15 microns thickness- inverse relation to their melting points. This thin film thus achieves the proper balance of flexibility, barrier performance, and cost of a flexible packaging application within the food, pharmacy, and, other applications.

Alloy 8011 is one of the low-pure aluminum alloys, which contains 98.5 to 99.5% aluminum with some copper and silicon.

8079 alloy-a high-purity aluminum alloy-usually ranges from 99.7% to 99.9% aluminum with very few impurities present.

Alloy 8011 has alloying elements that render it less pure than alloy 8079.

Alu foil 8079-O is counted as pure aluminum foil; it has very few impurities.

The 8011 alloy is resistant to corrosion and hence finds use as a food and beverage packaging.

Alu foil alloy 8079-O withstands corrosion better than alloy 8011 because it is a more pure form of aluminum.

The alloy 8011 is very malleable and ductile, which makes it applicable in diverse packaging requisites.

Alloy 8079: the hardness of alloy 8079 is tough whereas it is pretty brittle.

Applications:

.png)

8011 Alloy: Aluminum foils are often used in food packaging applications, such as containers, pouches and deep containers.

Alloy 8079: Alloy 8079 is very often assigned to those even special and pure applications like pharmaceutical, cosmetic, and electronic works.

8011 and 8079 aluminum alloys were reviewed for composition, purity, corrosion resistance, and structure, which were identified as the reasons behind the application potentialities in both packaging and industrial applications.

Together with high purity for corrosion resistance applications, alloy 8079 is best-suited for general food packaging while alloy 8011 generally finds use in general food packaging applications.

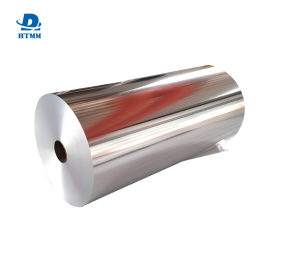

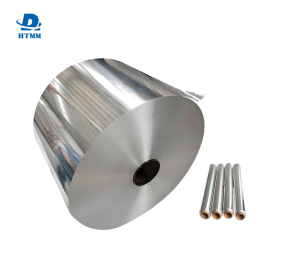

To achieve a smooth package, the 7 μm thickness of 8079-O Aluminum Foil is recommended.

Light and Light: The lightweight and 7 micron-thick aluminum foil provides the flexibility of adaption to a wide variety of products, including handbags, inner bags, and pouches.

This sheet shows softness and flexibility, which allow effortless picking, shaping, and forming of intricate designs.

Light, moisture, and water barrier properties: Thin 8079-O aluminum sheets are lightweight, but they perform excellently in protecting from light, water, and moisture.

Barriers are of maximum importance for the preservation of packaged goods, including food, pharmaceuticals, or other perishables.

Strength and Durability: The 8079-O aluminum sheets are lightweight but strong and tear-resistant and durable enough to withstand transportation and use.

This durability maintains the integrity of flexible packaging and resists manipulation and compromise of functionality.

8079-O alloy is having great workability, enabling welding of thin aluminum sheets, bending, and integration into complex designs on packaging.

8079 O 7 micron flexible packaging foil is an economical substitute to aluminum foil and other heavy barrier materials used in flexible packaging applications.

That cost efficiency is crucial for flexible packaging products sold in mass or bulk markets.

Lamination: 8079-O flexible packaging foil + with Plastic film or sheet

This layer is exploited in this composite structure to impart any specific function or decorative properties into the laminate through its barrier property.

This laminate structure makes use of the barrier properties available in aluminum foil to add a rich set of desired functional or decorative properties.

One of the thinnest aluminum foil at 7 micron, 8079-O is suitable for a wide range of food and pharmaceutical applications as well as industrial and consumer packaging, and many other industrial applications.

HTMM is an Aluminum foil manufacturer, we are a high quality aluminum foil manufacture, using 8079-O aluminum foil as the material, thickness of aluminum foil is 7 microns.

Aluminum foil 8079-O is designed clear and, it gives superior protection from light, moisture and air. Be it an expensive cosmetic, delicate medicine or delicate food, these strong barricades ensure your product stays intact with its integrity, taste and aroma. The 7 micron foil structure is as thin but strong weighs providing best in-class design while enabling complex and easy-to-use package designs to be fabricated without performance degradation or excessive power dissipation.

But whether it comes to the technological details of 8079-O aluminum foil, their advantages are much beyond this. At the same time, like any other responsible manufacturer, we profess our commitment towards sustainability and environmental responsibility. Aluminum foil is 100% recyclable, making it a great green option for businesses and consumers alike. Moreover its light weight makes it cheaper in transportation cost and carbon footprints, making it appealing for an alternative to packaging.

Explore the great properties and customizability of 8079-O 7 micron aluminum foil, and let us partner with you in making your packaging better. Reach out to us now and learn how high quality foil can enhance your products appearance to customers today.