Specification

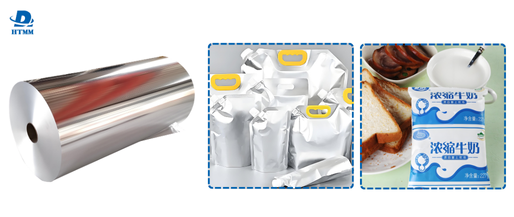

Aluminum Foil is not only cost-effective but also provides complete food protection. It is unrivaled as a barrier layer, completely excluding light, gases, oil and fat, volatile compounds and water vapor. Aluminium foil is temperature resistant, thermally stable and an extremely good conductor of heat. It is also strong, durable and safe for use in contact with all foodstuffs.

Details include:

| Type |

1235 laminated foil |

| Grade |

Food Grade |

| Alloy |

1235 8011 8079 |

| Temper |

O |

| Thickness |

0.0055MM-0.03MM |

| Width |

200MM-1600MM |

| Surface |

One side bright, One side matt |

| Packaging |

Free Fumigated wooden box |

| Applicable Laminated Types |

PET/AL/PE, BOPP/AL/PE, PAPER/AL/PE, NY/AL/PE |

| Application |

To be used for food packaging/ Cigarette Packaging after lamination,Snack packaging, coffee pouches, dairy wraps, beverage sachets, pharmaceutical packaging |

Excellent Barrier Performance

1235 laminated foil provides exceptional barrier properties against light, moisture, and oxygen, which contribute to extending the shelf life of perishables.

Soft Temper (O Condition)

The O-tempered state ensures flexibility and properties that are good to process, suitable for lamination, sealing, and forming applications.

Excellent Thermal and Electrical Conductivity

The alloy has excellent conductivity and maintains temperature stability for both cold and hot packaging.

Non-toxic and Odorless

Unlike other aluminum foil, 1235-O aluminum foil is considered safe for direct contact with food and alter the taste, texture, or aroma of the food packaged in it.

Excellent Laminating Material Compatibility

It adheres to paper, plastics, and adhesives, forming robust films of multi-layer composites of laminated packaging that are commonly found in pouch, lids, and wrap packaging systems.

FAQ: What is the difference between 1235 and 8079 aluminum foil? 1235 foil has greater levels of purity and is softer while 8079 is a stronger option with puncture resistance.

Is 1235-O aluminum foil safe for direct food contact? Yes, it is safe, non-toxic, and conforms to international food safety standards.

What is the most common thickness for soft packaging? Soft flexible laminated packaging typically uses 0.006 mm to 0.009 mm.

What materials can be laminated with 1235 foil?Commonly used with aluminum foil to enhance barrier properties are: PET, PE, BOPP, NY, and paper.

Can 1235 aluminum foil be printed or coated?Yes, it can be printed or colored, or with heat-sealing lacquer or other type of coating if needed.

What is the primary function of 1235 laminated foil packaging?Barrier protection against oxygen, moisture, and light is provided to keep products fresh.

Is 1235 aluminum foil recyclable?Yes, it is 100% recyclable and eco-friendly.

What industries use 1235-O aluminum foil most often?Food, beverage, pharmaceutical, and daily chemical industries.

How should 1235 laminated foil be stored?Keep laminated foil in a dry, clean area, away from moisture and corrosive materials.

Does HTMM offer custom solutions for laminated foil products?Yes, HTMM offers custom sizes, coatings and lamination combinations available to meet your specific packaging needs.