Specification

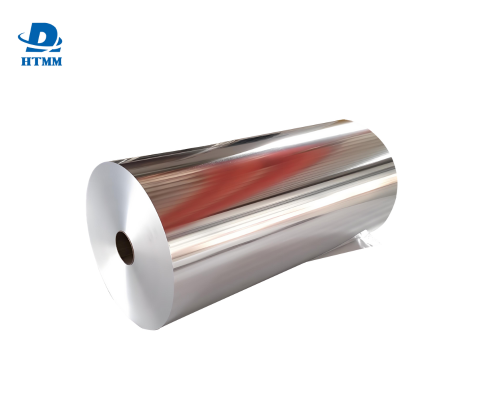

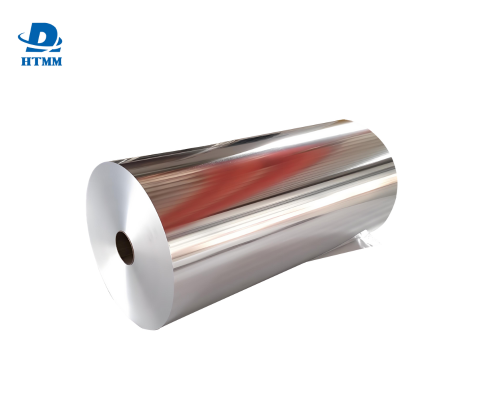

In addition to being recyclable, 8079 aluminum foil can easily be shaped into many forms, allowing for the production of a variety of snacks including crispy chips, savory nuts, sticky candies and dried fruits. 8079 aluminum foil is also well liked by snack manufacturers because of its ability to keep up with the fast-paced lifestyle of modern consumers. 8079 aluminum foil Jumbo Rolls can be customized to any width and thickness for smooth operation along any high-speed wrapping, sealing and printing equipment.

Details include:

| Type |

Flexible packaging aluminum foil |

| Grade |

Food Grade |

| Alloy |

1235 8011 8079 |

| Temper |

O |

| Thickness |

0.0055MM-0.03MM |

| Width |

200MM-1600MM |

| Surface |

One side bright, One side matt |

| Packaging |

Free Fumigated wooden box |

| Applicable Laminated Types |

PET/AL/PE, BOPP/AL/PE, PAPER/AL/PE, NY/AL/PE |

| Application |

To be used for food packaging/ Cigarette Packaging after lamination,Snack packaging, coffee pouches, dairy wraps, beverage sachets, pharmaceutical packaging |

Today’s consumers are concerned about protecting the environment, which is why many manufacturers are turning to 8079 aluminum foil for their packaging materials. Because it is 100% recyclable, using 8079 aluminum foil in their packaging allows brands to take a more environmentally safe approach to their environmental impact.

Protection Against Contamination: The inert properties of 8079 aluminum foil prevent any chemical reactions from taking place between the packaging and the ingredients that are used to make packaged snacks, providing a layer of protection against dust, bacteria and other outside contaminants throughout the transportation and storage processes of packaged snacks.

Heat Resistance: 8079 aluminum foil can withstand extreme heat levels of as much as...

Design & Aesthetic Appeal: Through the use of the smooth surface of the 8079 Aluminium foil, a bright coloured image of brand logos, nutrition labels & other attention-grabbing imagery can be printed with excellent clarity and enhance product visibility when displayed upon a store shelf.

Different spec levels for different snack types:Thin gauge (6 - 8 µm) - best suited for chips & similar dry, light weight snacks, as it is critical to keep the total weight and cost of the packaging as low as possible. These thin aluminium foils are usually found in flexible pouches or lidding films.

Medium gauge (10 - 12 µm) - This gauge is best for snacks that contain some moisture (nuts, candy), or require heat sealing. Medium gauge aluminium foils are much more tear-resistant compared to thin gauge foils.

Thick gauge (15 µm +) - This is for the heavy-duty or retortable type of snacks, and require the product to be very durable and able to withstand extreme heating/cooling or pressure during processing.

Benefits of HTMM in Manufacturing 8079 Aluminium Foil for Snack Packaging:HTMM is distinguished in the marketplace for its unwavering commitment to producing superior quality products and providing customer-driven solutions. This is especially important to HTMM in its manufacturing of 8079 aluminium foil for snack packaging. The following list outlines some of the benefits to HTMM that make them the best aluminium foil manufacturer for snack packaging products:

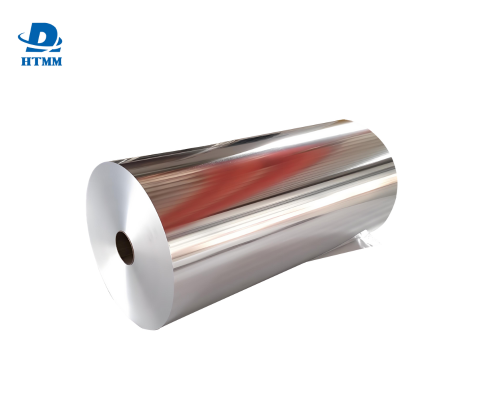

The Key for Snack Packaging Will Be to Control the Thickness and Width of the Snack Packaging MaterialsTo provide consistent sealing and packing for snack packaging, the thickness and width of the packaging material must be consistently controlled. HTMM uses advanced imported rolling mills and slitting machines to manufacture its 8079 aluminum foil to ensure that it meets the following:

Superior Surface PropertiesHTMM's 8079 aluminum foil has a smooth, pinhole-free surface. Pinhole openings in the surface of the aluminum foil reduce the aluminum foil's barrier function, making it prone to spoilage before the expiration date. By implementing a rigorous quality control process that includes a 100% visual inspection and testing, HTMM guarantees that every roll of aluminum foil produced has the high surface quality required for printing and sealing.

Cost-effective and Timely DeliveryHTMM has optimised mining and production efficiencies and built long-standing relationships with its raw material suppliers to deliver 8079 aluminium foil Jumbo Rolls at industry standard costs. In addition, HTMM takes advantage of an effective production schedule and a worldwide logistics network to provide timely delivery of standard between 7 and 12 business days, and custom orders 15 to 20 business days, for manufacturers to meet fast-paced manufacturing timelines.

FAQ:

The question of how long 8079 aluminum foil lasts or when it should be thrown away has no definitive answer because 8079 aluminum foil does not expire! When properly stored, in a cool dry place with ample ventilation and kept away from water & direct sunlight, the 8079 aluminum foil will continue to be usable indefinitely due to the high level of aluminum contained in the foil used for producing it (which prevents oxygen from occurring).

Is it Safe to Use 8079 Aluminum Foil to Wrap Up Microwaveable Food?Yes, it is safe! 8079 aluminum foil is capable of withstanding temperatures in excess of 230°C and will not adversely affect the microwaveable food inside – simply check the package for a "microwave-safe" label and refrain from placing any very acidic or excessively salty products in 8079 foil for prolonged time periods.

What is the Price Difference between 8079 Aluminum Foil & Plastics? Although the initial price of 8079 aluminum foil is higher than the price of plastics, over time it will actually save you money as a result of extending the shelf life of snacks and preventing spoilage. Therefore, 8079 aluminum foil can be regarded as an investment over time.

What is the Difference Between 8079 and 8011 Aluminium Foil for Snack Packaging? In summary, the differences are: 8079 aluminum foil has a greater percentage of aluminum than 8011 aluminum foil (99.7% or higher), along with better barrier properties; thus making it better suited for packaging moist or vapour containing products than does 8011 aluminum foil. Additionally, while 8011 aluminum foil costs less, it has lesser ductility and barrier performance compared to foil made of 8079 aluminium.

How do I find the best thickness of 8079 alloy aluminum foil to use when packaging snacks? Use an appropriate thickness depending on the type of snack. Dry snacks = 6-8 μm; moderately moist snacks = 10-12 μm; heavy-duty or retortable snacks = 15+ μm. Test samples of aluminum foil with the product in order to verify that your product will maintain freshness.

Can aluminum foil 8079 be laminated to another substrate (e.g. plastic, paper)? Yes. Typical lamination examples include foil laminated to polyethylene terephthalate (PET) and polyethylene (PE) for enhanced rigidity, puncture resistance, and resealability of many snack pouches that must be repeatedly opened and closed.

What is the average weight of a standard 8079 alloy aluminum foil jumbo roll? A standard 8079 alloy roll weighs between 1-3 tons and has a width of 1000-2200mm and a thickness of 6-15 μm. Custom weights can be made upon request.

Does HTMM provide technical guidance for using 8079 alloy aluminum foil?Yes. An experienced team at HTMM is available to assist you with Aluminum Foil Specification, Storage, Processing, and Troubleshooting to obtain optimum results using 8079 Aluminum Foil.

Is it acceptable to use 8079 alloy aluminum foil to package organic snacks?Yes, because 8079 aluminum foil is recyclable, non-toxic, and contains no harmful chemicals, it meets the requirements to be used for organic food packaging.