Specification

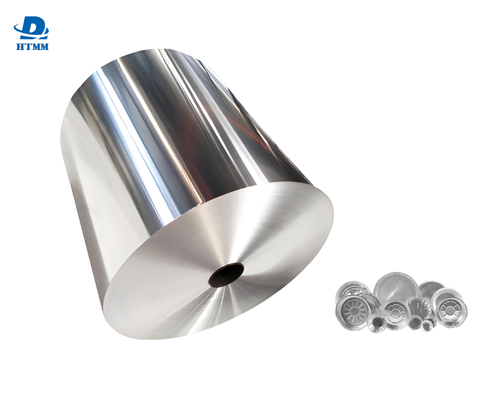

Aluminium foil has a variety of uses as an Intermediate Material in the manufacturing of Food Containers for Stamped, Folded and Embossed Forms. Of these Aluminum Alloys, 8011 provides the best balance of mechanical properties along with excellent forming properties.

Details include:

| Type |

Aluminium Foil for Food Container Application |

| Application |

For different food container applications, Such as dishes, plates, trays etc |

| Grade |

Food Grade |

| Alloy |

3003/8011/8006 |

| Temper |

H22 H24 H18 O |

| Thickness |

0.03MM-0.15MM |

| Width |

200MM-1300MM |

| Surface |

Both sides bright |

| Packaging |

Free Fumigated wooden box |

Use of Aluminum Foil in the Manufacturing of Food ContainersFood containers manufactured from either One-Time Use or Multiple Use Aluminium Foil are used to produce products such as: Food Trays, Lunch Boxes, Baking Pans, Airline Meal Trays and Take Out Food Containers. Before Used as Raw Material for these products; Aluminium Foil must be: Rolled, Annealed, Slited, and Stamped to its final thickness, strength and Surface Finish.

The alloy 8011 alloy is the material of choice for both fully automatic and semi-automatic food-grade aluminium foil container production due to its desirable properties when deep-drawn shaped and its excellent ability to maintain shape after being processed. The 8011 alloy foil food containers can be heated in either a conventional oven, steamed, or directly over an open flame, subject to the necessary degree of control. All these attributes enhance the customer experience.

The Performance Characteristics of the 8011-H22 alloy are well suited to making food containers.

The 8011-H22 alloy foil has a very high degree of Formability; with an optimal combination of Strength and Elongation, it provides the ability to manufacture complex formed shapes without cracking.

Food containers made from 8011-H22 exhibit very high Design Support and Rigidity, helping to facilitate effective stacking, storage, and shipment of food products.

Food container produced from the 8011-H22 alloy foil have a bright, clean, smooth surface, making them attractive to customers and meeting all of the sanitary requirements of food contact materials.

The 8011-H22 alloy foil is Food Safe and is in compliance with the International Standards for contact with food.

The 8011-H22 alloy foil performs very well in both High Temperatures and Low Temperatures.

Due to the many benefits of Food Container Aluminum Foil 8011 in H22 temper, it has been extensively developed for manufacturing rectangular trays, round containers, multi-compartment lunch boxes and bakery pans.

Uses Of 8011-H22 Aluminum Foil8011-H22 aluminum foil is used primarily for:

Meal trays for airline food service

Containers for take-away foods

Baking/cooking trays and cake pans

Grilling/roasting trays

Multi-compartment food containers

Packaging containers for ready-to-eat meals

Food Container Aluminum Foil 8011 is suitable for producing these types of food containers by providing good forming characteristics and sufficient strength.

Factors To Take Into Account When Producing Food Container Aluminum FoilTo produce the highest quality food container aluminum foil, the following considerations are important when producing aluminum foil foodcontainers:

Controlling thickness of aluminum foil: Controlling the thickness of aluminum foil will provide consistent forming results and prevent weak points from forming.

Surface cleanliness of aluminum foil: The minimum amount of contaminants on the surface of the aluminum foil will improve both food safety and presentation.

Mechanical properties of aluminum foil: The selection of the correct temper (e.g. H22) will allow the user to achieve the appropriate balance between strength and formability.

Rolling and annealing processes: The rolling of aluminum foil should be consistent; also the process of annealing should be consistent to achieve a uniform grain structure in the aluminum foil.

Edge quality of aluminum foil: It is important to have clean edges to reduce the risk of tearing during stamping or forming processes.

8011 Aluminum Food Container Foil FAQ 1. What's the main use of 8011 Food Container Foil?The main application of 8011 Aluminum Foil is to produce food containers, such as disposable and reusable aluminum food containers, trays, pans.

2. Why is the 8011 alloy the best option for use in food containers?The combination of excellent food safety compliance, good formability and strength makes it an ideal choice for food containers.

3. What are the benefits of using 8011-H22 foil?The balanced elongation and rigidity of this alloy makes it well suited for container forming.

4. Is 8011 direct food contact approved?Yes, 8011 Aluminium Foil meets international food-safe standards.

5. Can I use 8011 Food Container Foil in an oven?Yes, it can withstand heat, so it's great for oven use.

6. What thickness do I need for food containers? A typical thickness of 8011 Food Container Foil used when making food container products ranges from 0.05 mm to 0.12 mm depending on how the container design is constructed.

7. Can I recycle an aluminum container?Yes! 8011 aluminum containers can be recycled and are eco-friendly.

8. What type of surface will buyers want to see?It is important for buyers to see smooth and clean surfaces that do not have any pinholes or oil stains.

9. Do you provide special widths and specifications?Yes. HTMM will produce any width, thickness or temper of aluminum foil for food packaging according to your specifications.

10. How long will it take to deliver my order of 8011 aluminum foil?It normally takes between 30 and 45 days to deliver the order depending on the quantity and requirements.

.png)