Specification

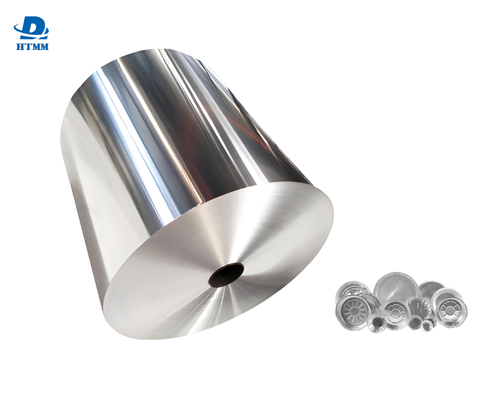

The average specification for the 8011 aluminium foil used to manufacture container type products is summarised in the following table:

Specification Category Details for 8011 Container Foil

Alloy 8011 (Al-Fe-Si alloy)

Temper (Common) O (Annealed), H22, H24, H26

Thickness Range 0.03 mm to 0.20 mm (30 to 200 microns)

Width Range 100 mm to 2000 mm (as coil)

Standard Core Diameter 76 mm (3"), 152 mm (6"), 405/505/508 mm

Surface Treatment Lubricated, non-lubricated, color-coated, embossed

Key Quality Standards Compliant with ASTM, EN, ISO, GB/T standards; meets FDA, SGS for food contact

Minimum Order Quantity (MOQ) Typically 3 to 5 metric tons for standard products (varies by supplier

Customization Services Available for thickness, width, surface finish, lubrication, printing, and alloy temper to suit specific container production needs

Details include:

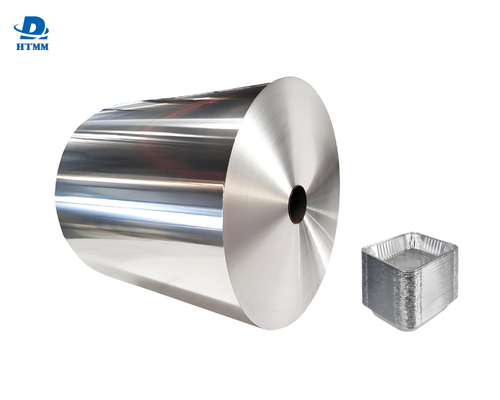

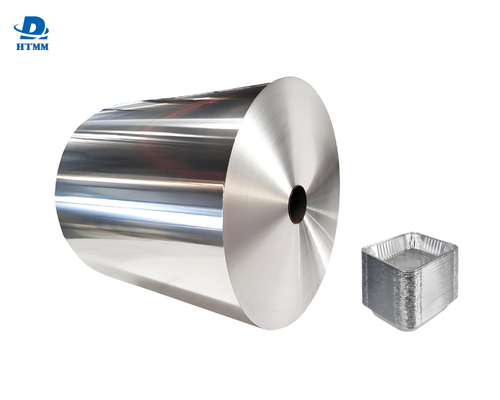

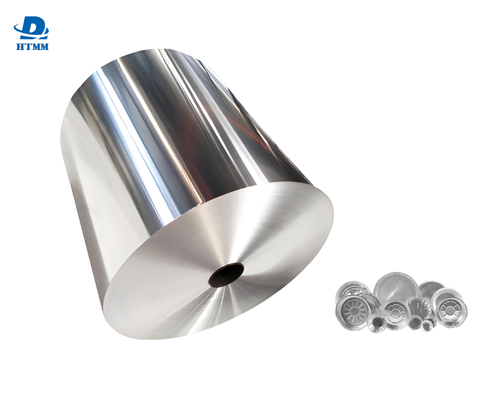

| Type |

Aluminium Foil for Food Container Application |

| Application |

For different food container applications, Such as dishes, plates, trays etc |

| Grade |

Food Grade |

| Alloy |

3003/8011/8006 |

| Temper |

H22 H24 H18 O |

| Thickness |

0.03MM-0.15MM |

| Width |

200MM-1300MM |

| Surface |

Both sides bright |

| Packaging |

Free Fumigated wooden box |

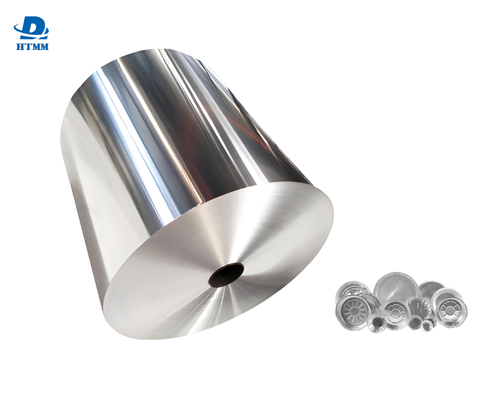

8011 aluminum foil has many application opportunities. This alloy is used in various ways: as a disposable tray or container for food service and meal delivery systems; as a foil pan or baking tray in the home; as a packaging material for food delivery, pre-cooked meals, and frozen meals; as an enclosure for pharmaceutical products using blister or strip packing; and as an industrial semi-rigid container used for technical and industrial products.

The 8011 aluminum foil is traded around the globe. The highest volume of consumption has not been specified; however, the three largest consuming sectors of this alloy are North America and Europe, which are mature markets with high levels of prepared food consumption and the need for environmentally-friendly materials; the Asia/Pacific region, which is growing rapidly due to urbanization and growth of food delivery services; and the Middle East and Australia, which are both growing markets in hospitality and food service industries.

Frequently Asked QuestionsWhat advantages does alloy 8011 have over pure aluminum when it comes to containers?(8011)aluminum, enhanced with the addition of Fe and Si elements, have considerable improvements in terms of yield and tensile strengths versus pure aluminum. Containers made from 8011 will have more rigidity and be puncture-resistant than containers made from pure aluminum; however, they will remain lightweight. It is safe to use 8011 aluminum foil in (microwaves)(ovens) – excellent heat resistance means it can be used for baking.

Microwave containers should be specially designed to be safe; for instance – no metal parts that might create arcing. 8011 foil offers greater flexibility during formation than 3003 or 3004, making it the most commonly used general-use alloy for container manufacturing; this means that if you just want to make cheap containers/packaging and/or use them for light-duty applications (i.e., only have a few items), use 3003; use 3004 if you want to make or package heavier items or if you are making longer/more complex (deeper-drawn) containers.

8011 aluminum foil will not only be recycled as-is many times but will also retain its original properties after many recyclings. Because 8011 aluminum foil can be completely recycled, it is one of the most environmentally-friendly choices you can choose to use for (packaging)(packages)(containers). A good manufacturer will certify the aluminum foil they produce meets food-contact standards set by international regulations, including the United States Food & Drug Administration; they may also let you know that their products have been verified independently by SGS.

.png)