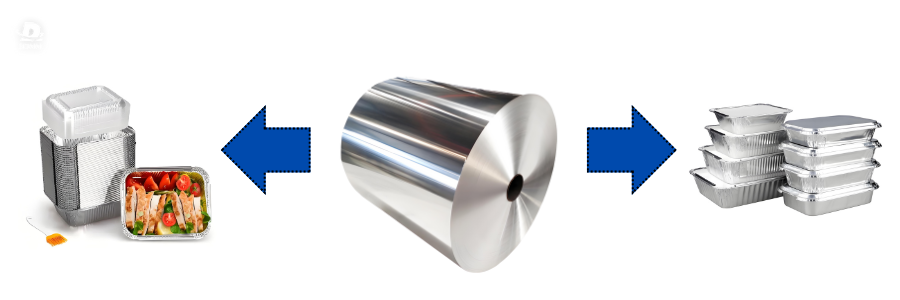

40 micron aluminum foil is actually aluminum foil with a thickness of 0.040 mm or 40 microns. This thickness is particularly suitable for making aluminum foil containers (different shapes, different uses). This is due to its excellent performance in durability, shape retention and processability, and this thickness is the most suitable thickness among aluminum foil raw materials. The specific information is as follows:

Thickness: 40μm/0.040mm/40microns

Main uses: Container foil raw materials can be used to produce disposable aluminum foil trays, packaging containers, frozen food containers, etc.

Standard alloys: 3003 H24 aluminum foil, 8011 H24 aluminum foil, 8006 H24 aluminum foil

| Item | Explanation |

| Thickness | 40 microns |

| Situation | H24 (partially cured) |

| Standard width | 300mm ~ 1000mm |

| Alloy type | 3003, 8011 |

| Main uses | Container foil manufacturing |

Why do customers always choose 40 mic aluminum foil?

Excellent heat resistance and durability

40 mic aluminum foil is thin but heat-resistant and can be put into the oven. When used as a container foil material, it has heat and freeze resistance. It is very friendly to food contact.

Moderate and commonly used thickness

It has stronger shape retention than 20~30 mic foil and better flexibility than 50 mic+. The thickness of 40mic is moderate, the durability is very strong, and the formability is very good.

Excellent sealing performance

40mic aluminum foil can prevent food from being exposed to external air or moisture after packaging. At the same time, the excellent barrier and moisture resistance provide great benefits for maintaining hygiene and freshness.

Which alloy should I choose? 3003 H24 vs 8011 H24

There are two most common container foil alloys, 3003 H24 and 8011 H24. Both container foils are very commonly used, so which alloy should you choose? At this time, what you need to do is to distinguish the differences between the two alloys of aluminum foil and see which one is most suitable for your aluminum foil container production. You can refer to the following table for selection:

| Item | 3003 H24 Aluminum Foil | 8011 H24 Aluminum Foil |

| Corrosion Resistance | excellence | very good |

| Formability | excellence | commonly |

| Robbery | middle | height |

| Price | slightly high | relatively inexpensive |

| Main Uses | advanced packaging, complex shaped containers | general food containers, mass produced products |

When making disposable aluminum foil containers with complex shapes: 3003 H24 is recommended.

For common aluminum foil container manufacturing and cost savings: 8011 H24 is recommended.

If you need to make aluminum foil containers used in aerospace: 8006 H24 is recommended.

So make the most appropriate choice based on your specific use and the complexity of your disposable container. If you still don’t know how to choose according to the suggestions, please contact us and we will help you solve various questions.

What are the technical requirements as a raw material for container foil?

From the customer’s point of view, it is not just the thickness that is important, but the entire production process.

Technical requirements:

High tensile strength: prevent rupture during packaging production

Uniform surface: ensure suitable coating and printing

Compatibility with machinery: high efficiency of container forming machines

Non-toxic: meet food safety standards

Common questions raised by customers about 40mic aluminum foil:

How stable is the container foil, is it easy to tear? → HTMM aluminum foil has a stability of more than 99%, is not easy to tear, and can be used with confidence.

Will the disposable aluminum foil container produced by container foil deform after freezing and heating? → It remains stable in the range of -40 to 250 degrees, is not easy to deform, is resistant to high temperatures, and can also be frozen.

How to solve the quality issues that customers are most concerned about?

Reasons: uneven thickness, tension control problems during molding

Solution: Adopt precision rolling process, thickness error within ±3%

Reasons: lack of tensile strength or microcracks

Solution: HTMM's high-purity alloy and strict quality control

Discoloration or dyeing

Reasons: unbalanced oxide layer or oil residue

Solution: Oil-free aluminum foil can be used

40 mic aluminum foil, also known as 40mic container foil, can be used to make disposable food containers with appropriate thickness, which can be used for daily catering, take-out services, restaurant use, large gatherings, food preparation, aviation catering industry, etc. The demand for container foil rolls is huge, so after understanding the various information of 40mic container foil, making a decisive choice can help you stand out in the aluminum foil container manufacturing industry.