In this article, we will explore the main advantages and uses of pharmaceutical aluminum foil in the medical packaging industry and explain why this material has become the standard choice of packaging experts.

Barrier Protection and Maintenance

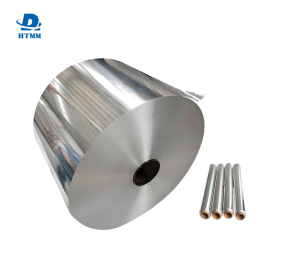

PACKAGING APPLICATION Aluminum pharmaceutical foil has been widely used in the medical packaging industry and serves as an effective barrier against a wide range of environmental threats. The nature of aluminum foil used for pharmaceutical packaging is such that it is highly resistant to light, oxygen, humidity, and other potentially damaging factors, so when the medical product is captured within The protection offers by the foil will ensure that it remains untainted.

.jpg)

This protective barrier ensures stability, potency, and efficacy of a multitude of medical and pharmaceutical products, ranging from sterile surgical supplies to perishable biopharmaceuticals.

In addition, the barrier properties of aluminum foil used for pharmaceutical packaging are especially useful in situations where the packaged articles are exposed to transportation, handling, and distribution. By protecting the contents from environmental influences, the aluminum foil giant rolls reduces the risk of contamination, corrosion and the like, ensuring the products remain effective and reliable.

Security Evidence and Proof of Security

Tamper-evident and tamper-resistant packaging is crucially essential for the pharmaceutical and medical fields, which are tightly controlled. Patients, healthcare professionals, and regulators require assurance of the authenticity and security of medical products that they have not been subject to adulteration or tampering throughout the supply chain.

That unique aluminum foil giant rolls crinkling sound and visual trepidation is an excellent match for packaging solutions that make it easy to see if a product has been tampered with or opened. Through the use of aluminium foil seals, lidding or other tamper-evident features, manufacturers have the opportunity to offer consumers a visible and distinct indication that a product’s quality has been preserved.

Aluminum foil giant roll is also used for its high barrier properties in the construction of tamper-gees and blister packs. The physical integrity and strength of the material avoids punctures, tears, and other physical damage, which would result in unauthorized access to the contents, in addition to protecti ng the packaged medical products.

Sterilization and Aspetic Packaging

In particular, the medical and pharmaceutical fields require the absolute barrier protection and microbial elimination provided by applied aluminum foil, and this barrier is a necessary state in the creation of necessary sterile or aseptic environments provided for by applied aluminum foil. The high temperature resistance, compatibility with common sterilization technologies (including gamma irradiation and autoclaving) and others make it a suitable option for packages that demand high level of microorganism control.

Aluminium foil-based packaging may be employed in the field of medical device to wrap medical product, so as to keep the products sterile, sterile dry, free from contamination. For products such as surgical instruments, wound dressings and injectable drugs, where even the smallest compromise of sterility can have a profound impact on patient safety and treatment efficacy – this is critical.

Moreover, the barrier performance of the aluminium foil maintains the sterile condition inside the packaging which avoids the entry of micro-organisms, dust and other impurities (UV light) which could lead to the break down of the packed objects.

Chemical compatibility and non-reactivity

Particularly, in the medical and pharmaceutical industry, the compatibility of the packaging material with the material that is packaged is of the greatest concern. Some drugs, biologics, and medical devices are vulnerable to being chemically affected or reacting with the packaging materials, potentially causing degradation and contamination of the product or in the worst case scenarios, the leaching of noxious compounds.

Aluminum foil has been known as a suit able packaging material for medical and pharmaceutical purposes because the foils are chemically inert, solvent averse, or reagent averse. The chemical resistance and neutrality of the foil enables the products to remain pure, bioactive and efficient for the entire shelf life of the packaging and there will be no interaction or contamination whatsoever.

It is this chemical compatibility, together with aluminum’s barrier properties, that renders it to be a critical packaging material for packaging of sensitive drugs, biologics and medical devices that need preservation of the integrity and safety of the product.

Versatility and Adaptability

The flexibility and the ability to be molded of aluminum foil have additionally led to its use throughout the medical packaging industry. Because the material can be easily formed, shaped, and incorporated into many packaging formats, it enables molders to deliver tailored solutions to the specific needs of medical devices.

Simple lidding/overwrapping features, as well as sophisticated multi-layer flexible designs, allow aluminum foil to fit form bags and pouches as well as plastic, metal and paper containers. This flexibility gives the manufacturers of medical and pharmaceutical supplies the ability to tailor the packaging to their own product’s requirements to ensure they are protected, presented and dispensed appropriately.

Moreover, the resistance of the aluminum foil to both plastics, papers and laminates, enables to manufacture hybrid solutions, which will combine the best properties of each of these compounds with consequent improvement in the performance and use flexibility of the medical packaging.