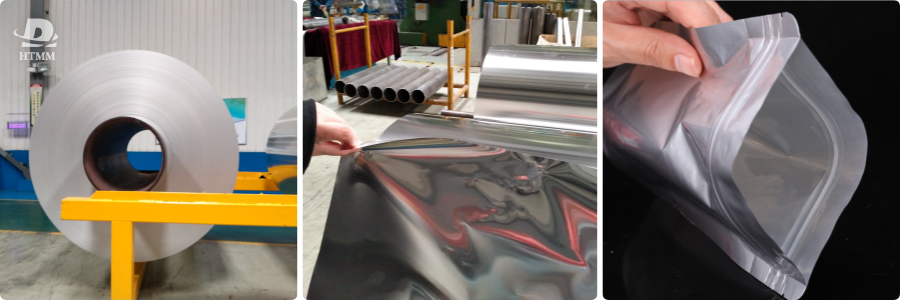

And in technical terms, this kind of ultra-thin aluminum foil is generally processed by high-precision rolling technology, and the raw material is selected from high-quality aluminum alloy. It is the selection of advanced raw materials--Aluminum 8079 Alloy which enable the product to still have excellent mechanical strength and corrosion resistance at an ultra-thin thickness. Simultaneously, aluminum foil can reach a high consistency and stability of 7 microns, 8 microns and 9 microns by finely controlling the rolling process, which supplies an effective basic material idea for lamination processing. Industry insiders said that the technology does not only save energy even in the production process, but also makes the final packaging products more flawless in appearance and performance, further highlighting the irreplaceable nature of the material for high-end packaging.

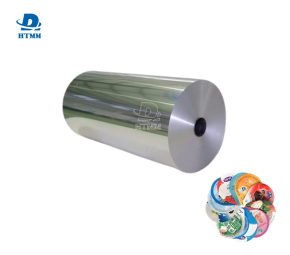

Application: this super-thin aluminum foil has great market performance in flexible packaging and high-end printing, and has been selected as the preferred packaging materials by many well-known brands. Due to its good barrier properties and reflective properties, this material is widely used for packaging processing of food, cosmetics and pharmaceutical products to ensure that the product obtains the best freshness and original appearance during transportation and storage. In particular, the industry consensus in the flexible packaging field is that 8079 Aluminum Foil For Flexible packaging has outstanding barrier and moisture-proof effects, which can greatly prolong the shelf life of products and enhance consumers' confidence in the brand and help enterprises establish a high-quality image.

It can be said that the process of producing high-end ultra-thin aluminum foil is excellent from the standpoint of production technology. High-efficiency rolling equipment and strict temperature control system make the aluminum foil couldn't avoid surface defects and thickness fluctuations during processing, which enables stable and consistent product quality. After many processes, the final product not only meets the high requirements of the lamination process, but also achieves the international leading level in various indicators, such as gloss, flexibility and puncture resistance. It is known as The Best Metal 8079 Aluminum Foil because the industry recognizes this product as one of the best performing aluminum foils on the market. Not only is this title an endorsement of the technical strength, but also, to a large extent, it is an endorsement of the product's performance in the application and the industry.

.png)

Feedback from the market indicates the laminated products with this particular ultra-thin aluminum foil have received a worldwide good reputation, especially in Europe, America, Southeast Asia and the Middle East. The related products are on fire and the market is growing. 8079 Aluminum Foil, as a high-performance packaging material, has excellent mechanical properties and outstanding barrier effect, which provides reliable technical guarantee for many brands. This aluminum foil able to meet the strict hygiene, environmental protection and safety standards, has become the main tool for many companies around the world to improve product added value from food packaging, pharmaceutical packaging to high-end gift boxes. Stable quality and high-end image make a lot of customers make it the preferred raw materials, at the same time driving the whole industry to a higher level.

In a long run, as the consumers' needs for the product quality and packaging will be further raised, the vast application of ultra -thin aluminum foil for lamination process will open to us. Based on the product served with superior performance and advanced production process of Aluminum 8079 Alloy, the product is currently at the forefront of the flexible packaging technology field, and must occupy the market in more technology-intensive and value-intensive application scenarios. Whether it is the emergence of new recyclable packaging materials, or used in precision instruments and high-end decoration application, it expected to be promoted qualitatively leap with this super-thin metal foil. Industry experts say The Best Metal 8079 Aluminum Foil not only represents a material innovation, but also a high standard of determination and confidence to packaging and have a better quality of the whole industry. HTMM aluminum foil product will surely lead a new round of packaging revolution in the future through continuous innovation and process optimization, adding new vitality and impetus to the global manufacturing industry.