Flexible packaging aluminum foil 1235 O is made from the well-known 1235 aluminum alloy and annealed to the O temper, the foil is a soft, flexible piece that is strong yet pliable. This new product starts with the 1235 alloy, a high purity, highly formable material, and features the O temper, which is produced by a special annealing process that imparts the required softness and malleability,at the same time, the oil is thoroughly removed in the annealing furnace, so that the 1235 aluminum foil for flexible packaging can be compounded with other materials and used safely in food.

Flexible Packaging Aluminum Foil 1235 O: A New Perspective on Package Manufacturing and Performance.Alloy 1235 aluminum foil for flexible packaging represents a significant breakthrough in packaging technology, presenting a range of advantages that differentiates them from their rigid aluminum foil predecessors. Improved flexibility means that it can easily be used in everything from stand-up and retort pouches to complex laminates. This flexibility allows brands to experiment with unique and creative packaging concepts, opening up opportunities for better branding, improved product visibility, and an elevated customer experience.

In flexible packaging, the main challenge lies in creating complex and eye-catching designs that appeal to consumers. And this is where the 1235 alloy really shines,compared with 8011 and 8079 alloys, 1235 alloy has better versatility and formability.

On the other hand, the 8011 and 8079 alloys, which are commonly employed in industry, have a comparatively high rigidity and are not well-suited to complex shaping, leading to less scope for innovative designs for packaging.

This new level of flexibility creates tremendous new opportunities for companies in every industry. Some of the best applications for which the alloy 1235 O flexible packaging aluminum foil is used effectively, include:

Stand-Up Pouches – The malleability and flexibility of the foil allows for intricate designs to be incorporated providing not only streamlined branding but also better product presentation, catching someone’s eye and enhancing the whole experiences of the product packaging.The food safety of 1235 O aluminum foil makes this material perfect for food and drug packaging.

.jpg)

Retort Pouches: Its thermal conductivity is assisting with retort processing, which is progressively being utilized to ensure the quality of packed food items and product shelf life.

Coextrusions and Laminated Structures: The 1235 O food grade flexible packaging aluminium foil roll offers excellent formability and as such can easily be combined with other thermoplastic films to create laminates that capitalise on the barrier properties of aluminum in addition to the flexibility of flexible films。This type of material is widely used in various snack packaging bags.

Additional Applications: The versatility of 1235 O food grade flexible packaging aluminium foil roll also enables the design of custom-shaped blister packaging, offering tailored protection and aesthetic appeal for various products, from pharmaceuticals to consumer electronics.

Lidding and Sealing Solutions: The malleability and heat-sealability of the foil also make it suited for lidding and sealing applications to provide closure that is tightly sealed and protects the products.

Aluminum foil 1235 O has long been a highly reliable choice in aluminum foil, but Flexible Packaging Aluminum Foil 1235 O boasts more than just flexibility. It retains the wonderful oxygen, moisture and light barrier properties of those materials to help ensure the product inside can still be protected and stay fresh. Its thermal conductivity also makes it a perfect fit for applications that require either heat sealing or retort processing.

Maintaining high purity and consistent composition of the 1235 alloy creates a strong barrier layer that effectively protects the contents of the package, increasing the shelf life of the product and protecting its integrity. Such performance advantage is especially important when shipping sensitive goods like food, pharmaceutical and electronic products, where the merest breaking of the barrier could have adverse effects.

The barrier properties of 8011 and 8079 are also good and they also provide good performance for food packaging, but the barrier properties of 1235 alloy are even better which makes this alloy as preferred grade for flexible packaging applications.

In the current era of packaging innovation, sustainability is not one to overlook, and the Flexible Packaging Aluminum Foil 1235 O also excels in this area. Our foil is made of inherently recyclable material, and is designed to fit easily into existing recycling channels as a solution that lasts and aligns with the circular economy, and decreases the environmental footprint of packaging waste.

The high purity level and uniform composition of the 1235 grade ensure easy integration with existing aluminium recycling streams, thus supporting the circular economy and reducing the environmental footprint of packaging waste. On the other hand, the presence of some impurity elements in 8011 and 8079 alloys may make them difficult to reintegrate into the recycling process.

With an increasing demand for sustainable and environmentally friendly packaging solutions, the 1235 alloy's superior recyclability and complementarity of circular economy principles make it an optimal choice for progressive businesses in the flexible packaging market.

As a result, these unparalleled qualities make the 1235 alloy the one and only option for flexible packaging applications with considerably higher advantage when compared to the widely used 8011 and 8079 alloys. With its excellent workability, full recycled materials, high impact strength and corrosion resistance, the 1235 alloy offers companies innovative options for all types of cute shielding and sustainable product preservation.

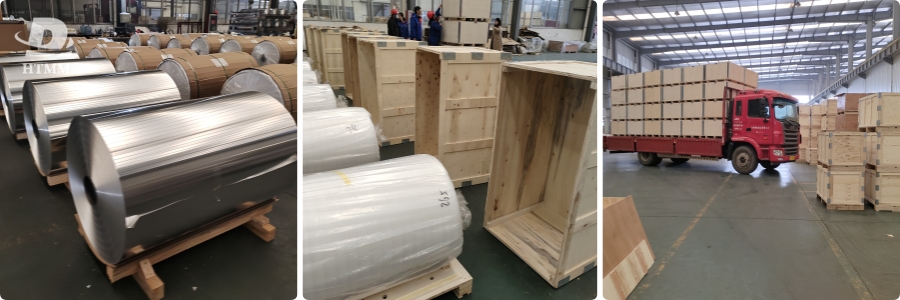

And with this, we conclude the latest contribution to the flexible packaging community, the Flexible Packaging Aluminum Foil 1235 O, a reflection of both the life-long journey of improvement at HTMM Aluminum Foil Company and also one of the most remarkable answers to the quest for sustainable and practical packaging in the modern-day! By producing this exceptional material, HTMM Aluminum Foil can help food packaging companies around the world test and set the limits of future flexible packaging, creating new levels of performance with less waste.