The Growing Demand for Takeaway Containers in Saudi Arabia

The catering market in Saudi Arabia has grown rapidly in recent years. With people's increasing pace of life and work, the demand for takeaway and delivery food services has increased significantly. Many restaurants and food shops have started offering takeaway and delivery options to meet customers' needs. As a result, the demand for disposable takeaway containers has also grown strongly. Aluminum foil is widely used as the primary raw material for making takeaway containers due to its many advantages.

Properties and Applications of Aluminum Foil

Aluminum foil is a very versatile material with good formability, tight gauge control, and high purity. The most commonly used alloys for foil production include 3003 H24 aluminum foil which has excellent strength and softness properties. 3003 foil provides strength for shaping containers while maintaining flexibility. It can be easily formed into containers, trays, bowls and other types of food packaging through various methods like die cutting, thermoforming etc. Its dead fold properties allow creasing without cracking.

The light weight and low cost of aluminum foil make it an economical choice for disposable food packaging. The shiny surface of foil provides an attractive look for food presentation. Its moisture barrier property helps preserve the freshness, taste and quality of food. Aluminum is completely recyclable and reusable, giving foil packaging sustainability advantages over alternatives. Its barrier to light also helps protect foods from color fade. Aluminum foil is widely used to package snacks, fast foods and takeaways due to these advantages.

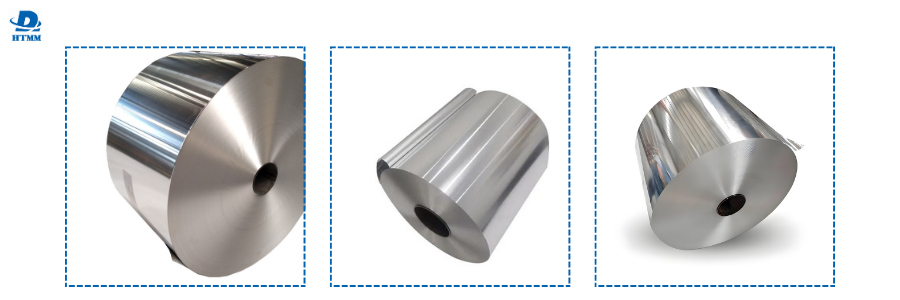

Raw Material Requirements for Jumbo Roll Aluminum Foil

For production of large volumes of takeaway containers, jumbo rolls of aluminum foil are usually required by container manufacturers and converters. HTMM is a leading global supplier of high-quality aluminum foil, including 50kg jumbo rolls of 3003 H24 alloy in thicknesses from 15mic to 80mic. Jumbo rolls allow efficient, continuous production of containers on automated lines. The rolls have excellent gauge consistency and surface properties for optimum conversion. For catering containers, foil thicknesses between 20- 40mic are commonly used. Thinner gauges below 20mic are flexible but less durable for containers holding hot or wet foods. Thicker foil above 40mic lacks optimal formability.

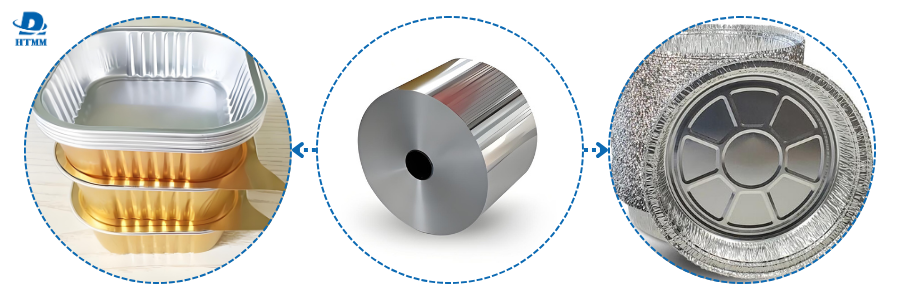

Production Process of Aluminum Foil Takeaway Containers

The global aluminum foil provider supplies foil in heavy duty jumbo rolls suitable for container production. The foil is first uncoiled from the parent roll and slit or sheared into narrower parent rolls of required widths. These parent rolls are then fed into multi-cavity presses or rotary dies for high-speed, synchronized forming and creasing of container shapes. Advanced triple-draw dies allow production of complex 3D designs. Formed foil sheets are then die cut to release individual containers. Some types of containers may undergo additional operations like folding, crimping or assembly. The formed foil takeaway containers are then neatly packed for delivery to customers.

Advantages of Using Aluminum Foil in Takeaway Containers

HTMM's high-purity, premium grade foil is preferred for takeaway container applications due to its superior functionality and performance advantages. One of the main benefits is excellent formability allowing production of attractive containers with complex patterns using multi-cavity dies. The foil retains its shape well without any wrinkles. Its dead fold properties ensure containers can be neatly folded without cracking.

Aluminum foil is very lightweight, allowing minimal shipping costs. Yet it has strong barrier properties to preserve food quality during storage and transport. This retains customers and helps build brand loyalty for caterers. Foil is highly durable and resistant to impacts, ensuring containers maintain their shape and protect contents even when stacked or carried. It can withstand temperatures from below freezing to above 200°C, accommodating both hot and cold foods.

Aluminum is fully recyclable, giving foil packaging sustainability benefits. It takes over 99% less energy to produce aluminum foil from recycled material compared to primary production. This reduces environmental impact. Aluminum foil is also non-toxic and FDA approved for direct food contact, reassuring consumers about food safety.

Growth Potential for Aluminum Foil Takeaway Containers

The catering market in Saudi Arabia is expected to continue growing in size with increased spending on food deliveries and takeaways. This rising demand profile indicates huge potential for aluminum foil to grow as a key raw material for disposable food packaging. Foil provides an optimized combination of functionality, cost and sustainability highly valued in the single-use container market. The environmental benefits of aluminum also align well with the Kingdom’s progressive ‘Vision 2030’ strategy promoting green initiatives.

HTMM is well-placed to meet any future demand surge with its extensive global production capabilities and track record as a major foil supplier to the region. The company will continue innovations to develop even more optimized foil grades, widths and finishes for this strategic market segment. HTMM’s focus on superior service, quality and sustainability also make it a preferred partner to container producers catering to the booming Saudi catering industry.

In summary, aluminum foil is the ideal raw material choice for large-scale takeaway food container manufacturing given its excellent formability, barrier properties, lightweight and recycling advantages. Jumbo rolls of premium 3003 H24 alloy foil from global supplier HTMM ensure reliable, high productivity conversion into professional-quality packaging solutions. With the fast growth of food delivery and takeaway services in Saudi Arabia, aluminum foil is poised for substantial market expansion supported by favorable demand drivers. HTMM is well equipped to efficiently meet any future requirement increases with next-generation foil products.