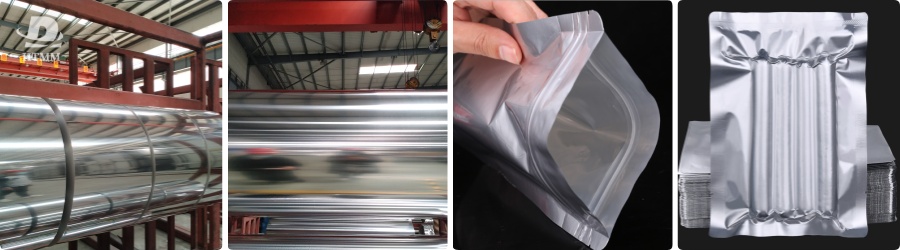

In particular, Alufoil 1235-O offers a good balance of strength and thickness, opening up many areas of application. With a thickness of only 0.07 g/m2, this non-stick paper adheres to food without losing its cooking properties. By improving the quality of the paper while maintaining its shape, designs can be easily created on canvas and cardboard. In addition, the 7-micron thickness of aluminum alloys in large parts can be transformed into special insulation parts and products made of high-tech metals.

At a basic level, specific properties are required, such as energy-to-weight ratio, strength-to-weight ratio, speed and power. Aluminum foil thickness 7 microns Sustainability in the printing industry; people still need to use advanced material handling technologies and new detection technologies.

Most FMCG products are now packaged in Alufoil 1235, which is drawn through deep-cooling foils or converted into flexible coatings. 7 micron aluminum foil use Its anti-reaction and corrosion-resistant properties ensure long-term packaging stability and energy savings throughout the manufacturing process. Compared to its size, this paper also has exceptional thermal properties for applications requiring insulation or heat sealing.

It is commonly used by leading brands for packaging chips, biscuits, chocolate, bakery products and other food products. The non-stick surface allows for better and tighter packaging, extending shelf life and enhancing the aesthetics of retail stores. In addition to food products, these conventional foils are also used as substrates in various industries and are then processed into technical foils by coating, printing or coating according to specific requirements.

All in all, the success and performance of Alufoil 1235-O in the past decade is due to its ability to adapt to a wide range of requirements. At HTMM, our vision is to be the company and driver behind the quality of aluminum models. With its durability and new limits, we believe that Alufoil 1235-O will make future applications relevant today.